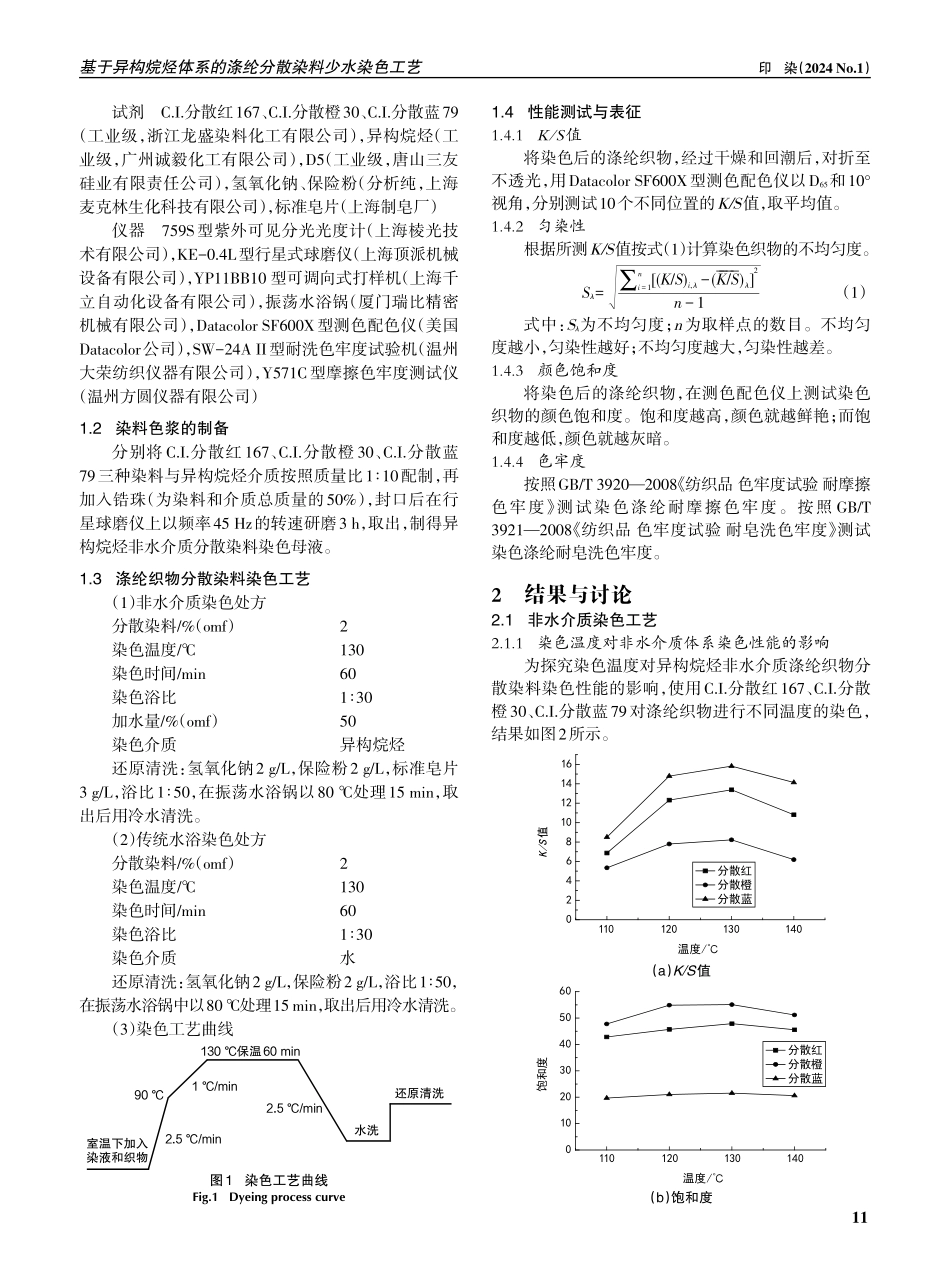

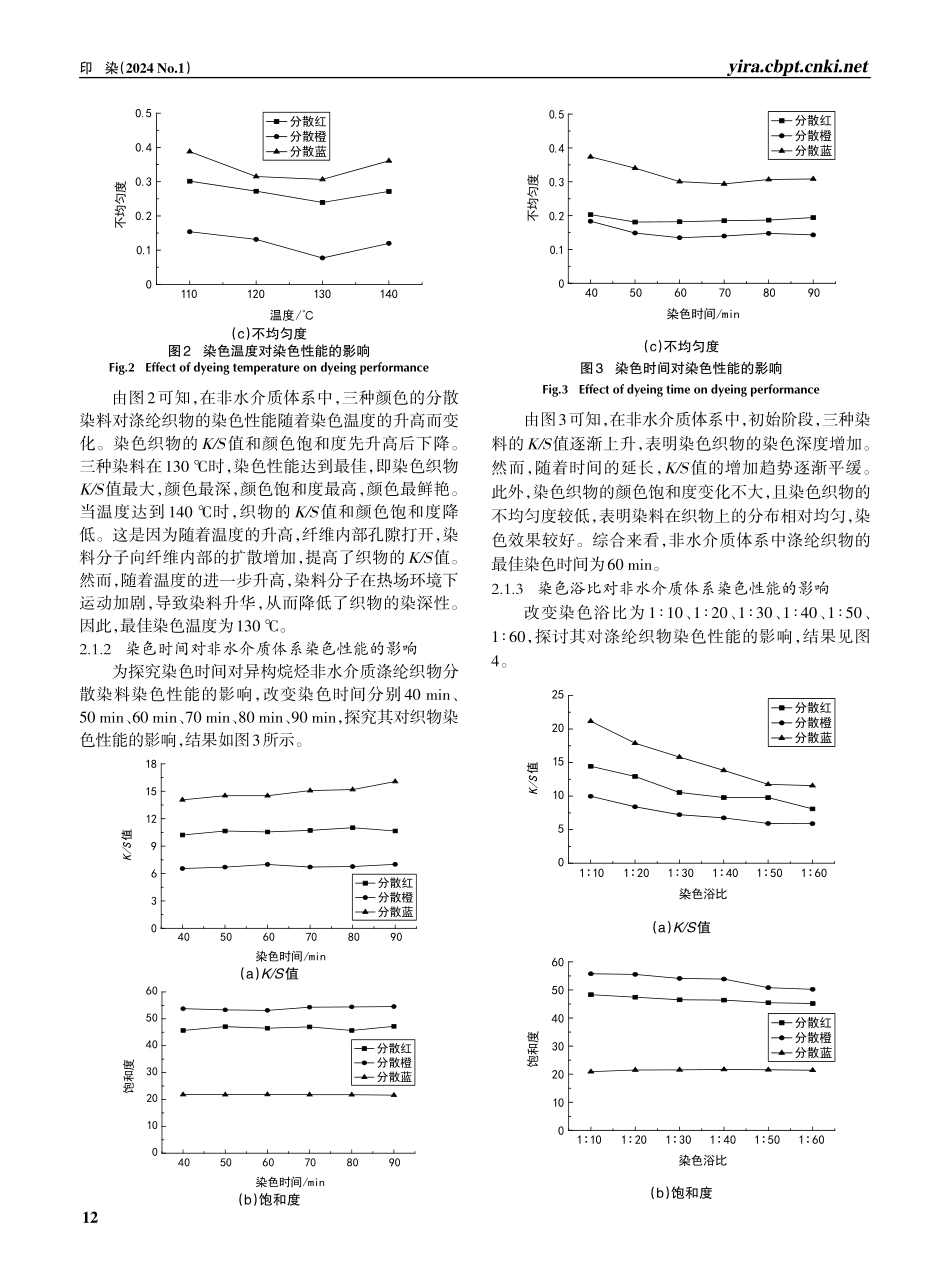

印染(2024No.1)yira.cbpt.cnki.net基于异构烷烃体系的涤纶分散染料少水染色工艺张尚坤1,2,张生强3,史建平3,徐爱如3,马颖媛1,2,胡毅1,2æèççöø÷÷1.浙江理工大学纺织科学与工程学院,浙江杭州310018;2.浙江理工大学生态染整技术教育部工程研究中心,浙江杭州310018;3.湖州福美达纺织有限公司,浙江湖州313012摘要:采用一种新型异构烷烃介质对涤纶织物进行分散染料少水染色,探究了染色温度、染色时间、染色浴比以及水的添加量对织物染色性能的影响,并与传统水浴染色织物的色牢度进行对比。结果表明:在染色温度为130℃,染色时间为60min,染色浴比1∶30,加水量为50%(omf)时,织物的K/S值最大,颜色饱和度最高,匀染性最好;同时,新型异构烷烃介质少水染色织物的耐皂洗、耐摩擦色牢度均与传统水浴的染色水平相当。关键词:异构烷烃;少水染色;涤纶织物;分散染料;染色性能中图分类号:TS193.638文献标志码:ADOI:10.3969/j.yinran.202401012LesswaterdyeingprocessofpolyesterwithdispersedyesbasedonisomericalkanesystemZHANGShangkun1,2,ZHANGShengqiang3,SHIJianping3,XUAiru3,MAYingyuan1,2,HUYi1,2æèççççöø÷÷÷÷1.CollegeofTextileScienceandEngineering,ZhejiangSci-TechUniversity,Hangzhou310018,China;2.EngineeringResearchCenterforEco-DyeingandFinishingofTextiles,MinistryofEducation,ZhejiangSci-TechUniversity,Hangzhou310018,China;3.HuzhouFumeidaTextileCo.,Ltd.,Huzhou313012,ChinaAbstract:Thisarticlestudiesanovelmethodfordyeingpolyesterfiberswithdisperseddyesinanewtypeofisomericalkanemedium.Theeffectsofdyeingtemperature,dyeingtime,liquorratioandwatercontentonthedyeingperformanceoffabricsareinvestigated,andthecolorfastnessofthedyeingswiththenovelmethodiscomparedwiththatoftraditionalwaterbath.Theresultsshowthatdyedat130℃for60minwithbathratioof1:30andwateradditionof50%(omf),thefabrichasthehigherK/Svalue,colorsaturationandlevelness,aswellasthesimilarcolorfastnesstosoapingandrubbing,comparedwithtraditionalwaterbath.Keywords:isoalkanes;lesswaterdyeing;polyesterfabric;dispersedyes;dyeingperformance涤纶作为产量最大的化学纤维之一,被广泛应用于建筑材料、工业用布、汽车内饰和纺织品原材料[1]。传统的涤纶织物主要利用分散染料在...