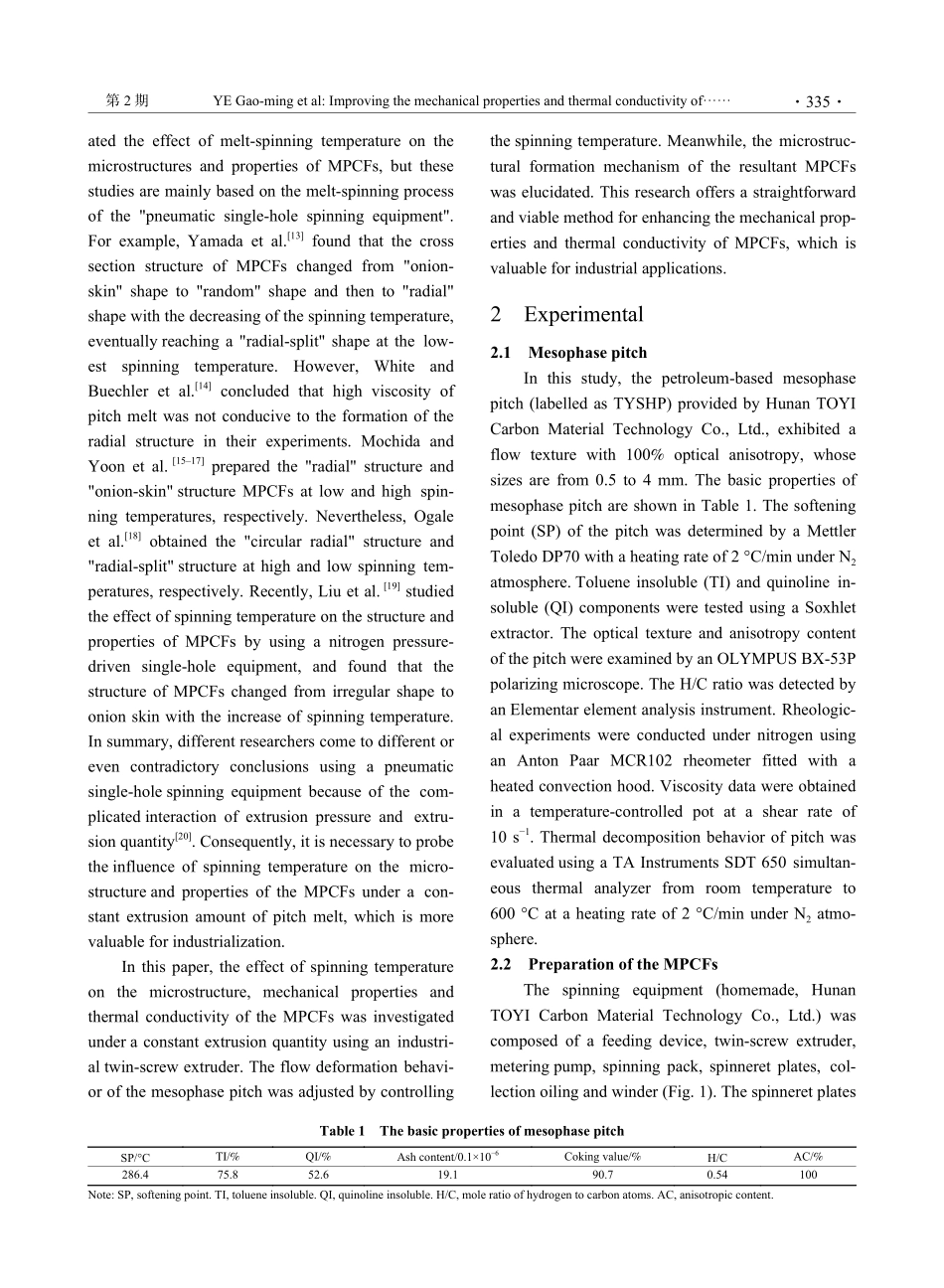

Citethis:NewCarbonMaterials,2024,39(2):334-344DOI:10.1016/S1872-5805(24)60826-7Improvingthemechanicalpropertiesandthermalconductivityofmesophase-pitch-basedcarbonfibersbycontrollingthetemperatureinindustrialspinningequipmentYEGao-ming1,†,SHIKui1,†,WUHuang1,HUANGDong1,2,YEChong1,2,4,*,OUYANGTing1,ZHUShi-peng3,*,FANZhen3,LIUHong-bo1,LIUJin-shui1,2,4,*(1.CollegeofMaterialsScienceandEngineering,HunanProvinceKeyLaboratoryforAdvancedCarbonMaterialsandAppliedTechnology,HunanUniversity,Changsha410082,China;2.HunanProvinceEngineeringResearchCenterforHighPerformancePitch-basedCarbonMaterials,HunanToyiCarbonMaterialTechnologyCo.,Ltd.,Changsha410000,China;3.KeyLaboratoryofAdvancedFunctionalCompositeMaterials,AerospaceResearchInstituteofMaterialsandProcessingTechnology,Beijing100076,China;4.StateKeyLaboratoryofAdvancedDesignandManufacturingforvehiclebody,HunanUniversity,Changsha410082,China)Abstract:Mesophase-pitch-basedcarbonfibers(MPCFs)werepreparedusingindustrialequipmentwithaconstantextrusionrateofpitchwhilecontrollingthespinningtemperature.Theinfluenceofspinningtemperatureontheirmicrostructures,mechanicalprop-ertiesandthermalconductivitieswasinvestigated.SEMimagesofthefracturedsurfaceofMPCFsshowthatthegraphitelayershavearadiatingstructureatallspinningtemperatures,butchangefromthefine-and-foldedtothelarge-and-flatmorphologywhenincreas-ingthespinningtemperaturefrom309to320oC.AtthesametimethethermalconductivityandtensilestrengthoftheMPCFsre-spectivelyincreasefrom704W·m−1·K−1and2.16GPaat309oCto1078W·m−1·K−1and3.23GPaat320oC.Thelowerviscosityandtheweakerdie-swelleffectofmesophasepitchattheoutletsofthespinneretsatthehigherspinningtemperaturecontributetotheimprovedorientationofmesophasepitchmoleculesinthepitchfibers,whichimprovesthecrystallitesizeandorientationoftheMPCFs.Keywords:Mesophasepitch;Spinningtemperature;Carbonfiber;Highthermalconductivity;Mechanicalproperties1IntroductionMesophase-pitch-basedcarbonfibers(MPCFs)havebeenwidelyusedinthefieldsofaerospace...