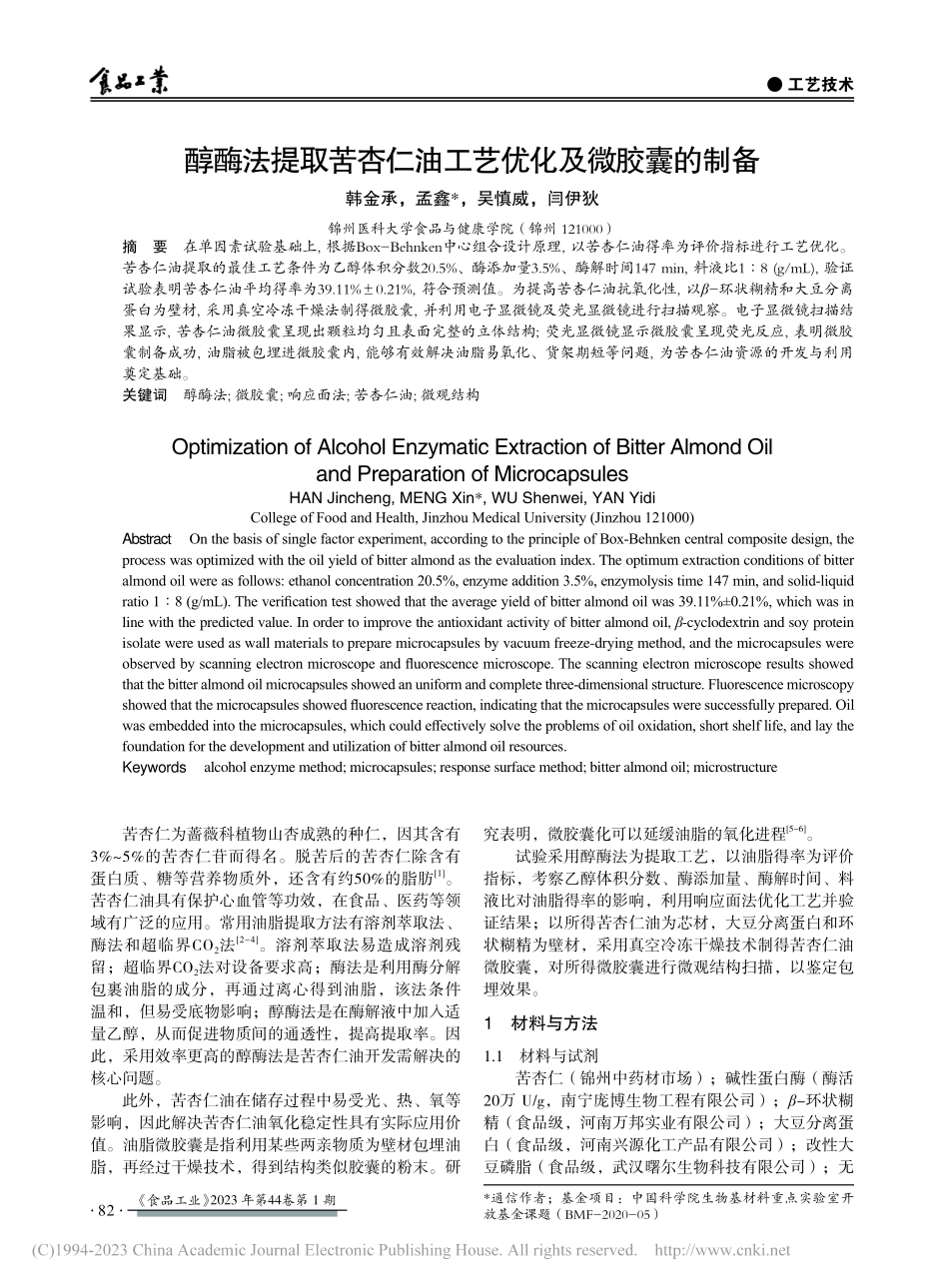

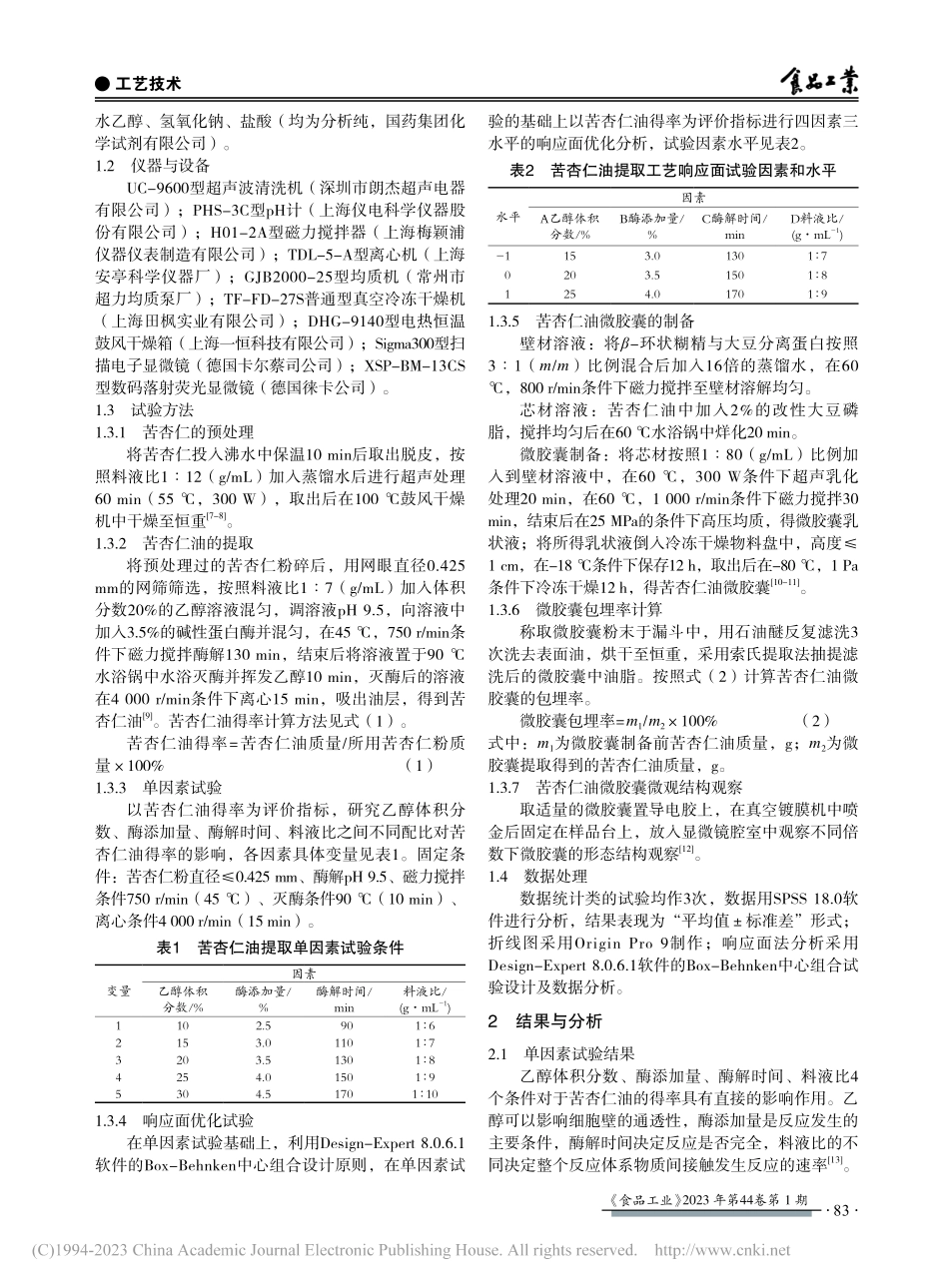

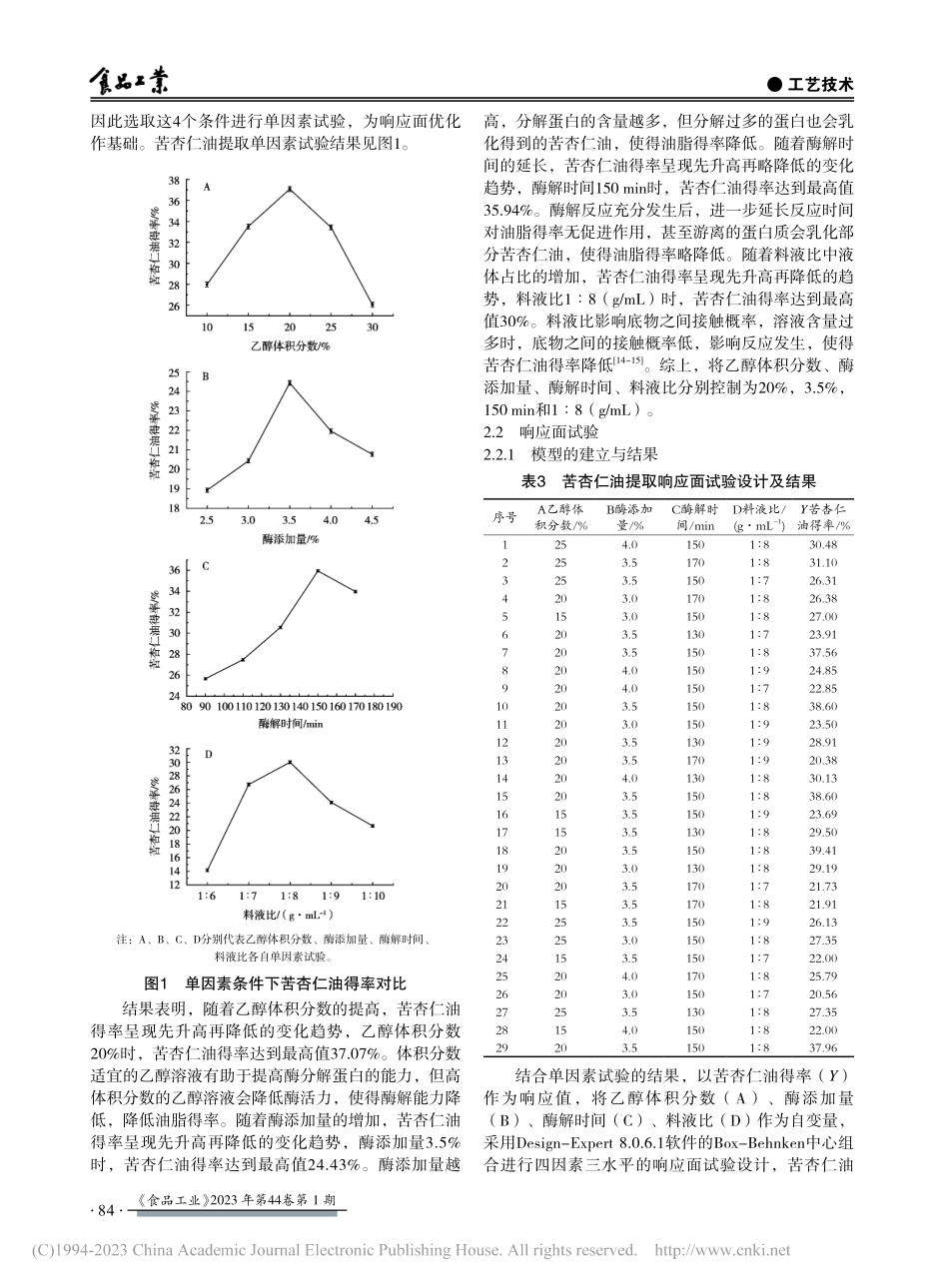

《食品工业》2023年第44卷第1期82工艺技术醇酶法提取苦杏仁油工艺优化及微胶囊的制备韩金承,孟鑫*,吴慎威,闫伊狄锦州医科大学食品与健康学院(锦州121000)摘要在单因素试验基础上,根据Box-Behnken中心组合设计原理,以苦杏仁油得率为评价指标进行工艺优化。苦杏仁油提取的最佳工艺条件为乙醇体积分数20.5%、酶添加量3.5%、酶解时间147min,料液比1︰8(g/mL),验证试验表明苦杏仁油平均得率为39.11%±0.21%,符合预测值。为提高苦杏仁油抗氧化性,以β-环状糊精和大豆分离蛋白为壁材,采用真空冷冻干燥法制得微胶囊,并利用电子显微镜及荧光显微镜进行扫描观察。电子显微镜扫描结果显示,苦杏仁油微胶囊呈现出颗粒均匀且表面完整的立体结构;荧光显微镜显示微胶囊呈现荧光反应,表明微胶囊制备成功,油脂被包埋进微胶囊内,能够有效解决油脂易氧化、货架期短等问题,为苦杏仁油资源的开发与利用奠定基础。关键词醇酶法;微胶囊;响应面法;苦杏仁油;微观结构OptimizationofAlcoholEnzymaticExtractionofBitterAlmondOilandPreparationofMicrocapsulesHANJincheng,MENGXin*,WUShenwei,YANYidiCollegeofFoodandHealth,JinzhouMedicalUniversity(Jinzhou121000)AbstractOnthebasisofsinglefactorexperiment,accordingtotheprincipleofBox-Behnkencentralcompositedesign,theprocesswasoptimizedwiththeoilyieldofbitteralmondastheevaluationindex.Theoptimumextractionconditionsofbitteralmondoilwereasfollows:ethanolconcentration20.5%,enzymeaddition3.5%,enzymolysistime147min,andsolid-liquidratio1︰8(g/mL).Theverificationtestshowedthattheaverageyieldofbitteralmondoilwas39.11%±0.21%,whichwasinlinewiththepredictedvalue.Inordertoimprovetheantioxidantactivityofbitteralmondoil,β-cyclodextrinandsoyproteinisolatewereusedaswallmaterialstopreparemicrocapsulesbyvacuumfreeze-dryingmethod,andthemicrocapsuleswereobservedbyscanningelectronmicroscopeandfluorescencemicroscope.Thescanningelectronmicroscoperesultsshowedthatthebitteralmondoilmicrocapsulesshowedanuniformandcompletethree-dimensionalstructure.Fluorescencemicroscopyshowedthatthemicrocapsulesshowedfluorescencereaction,indicatingthatthemicrocapsulesweresuccessfullyprepared.Oilwasembeddedintothemicrocapsules,whichcouldeffectivelysolvetheproblem...