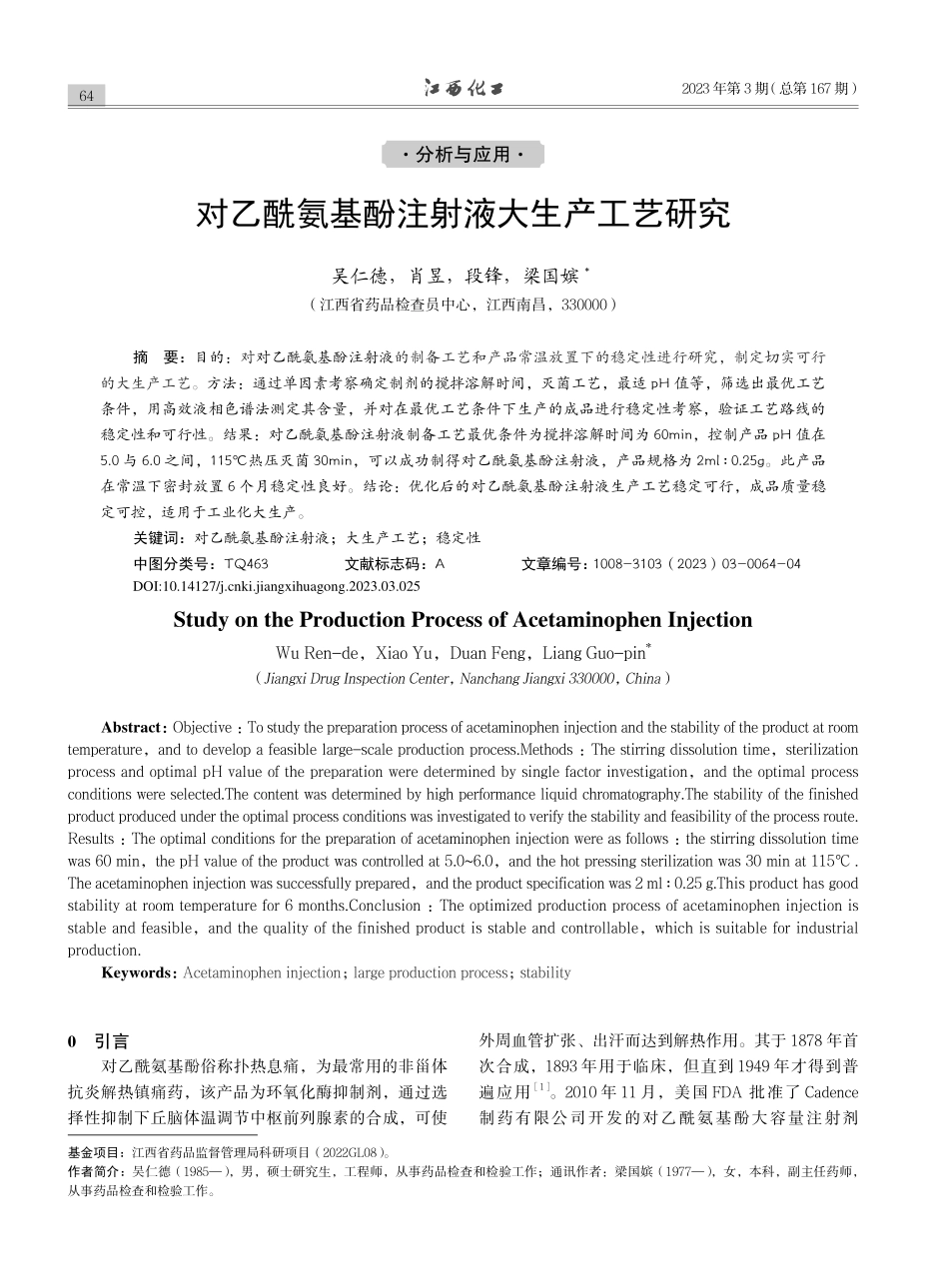

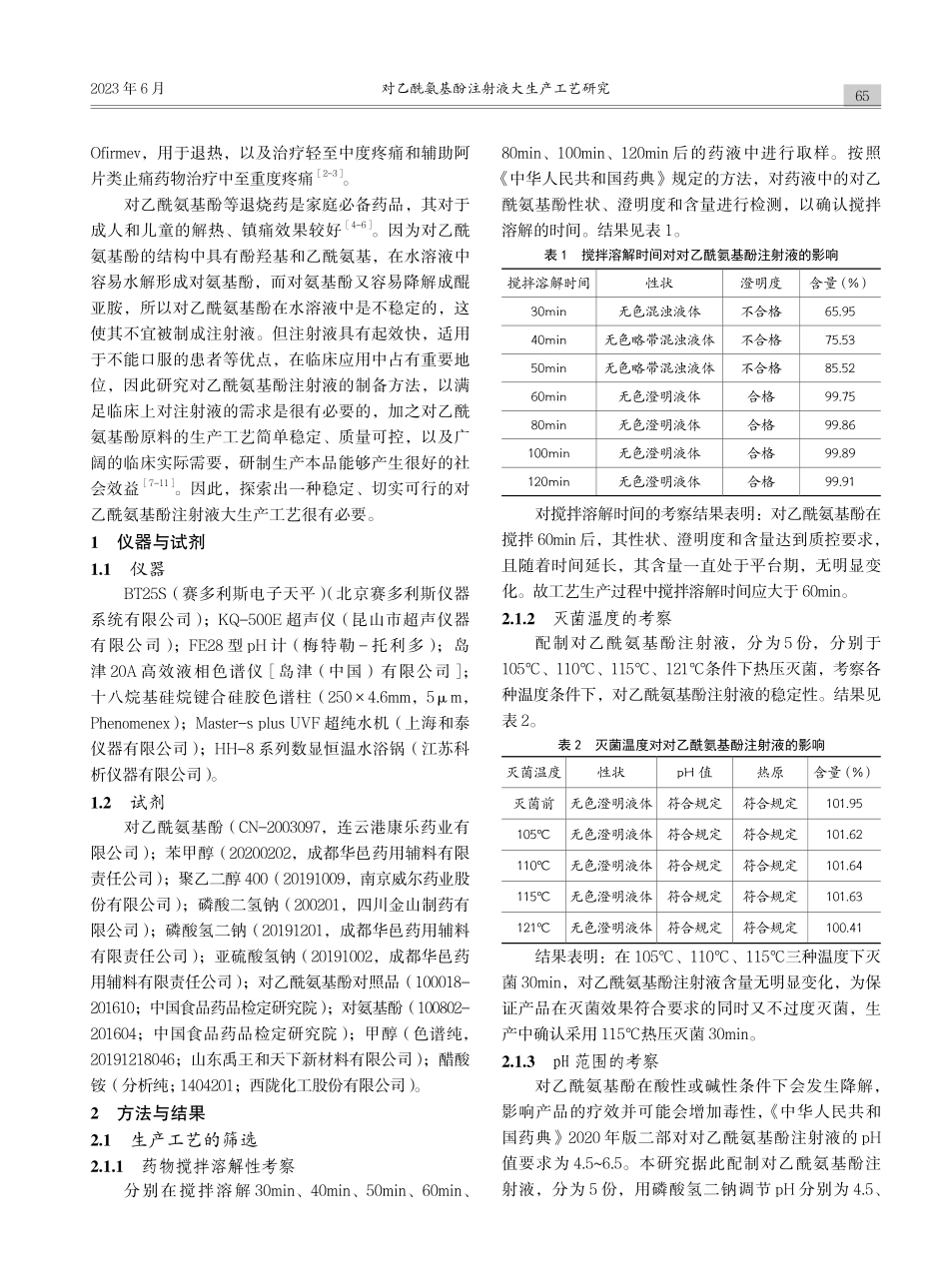

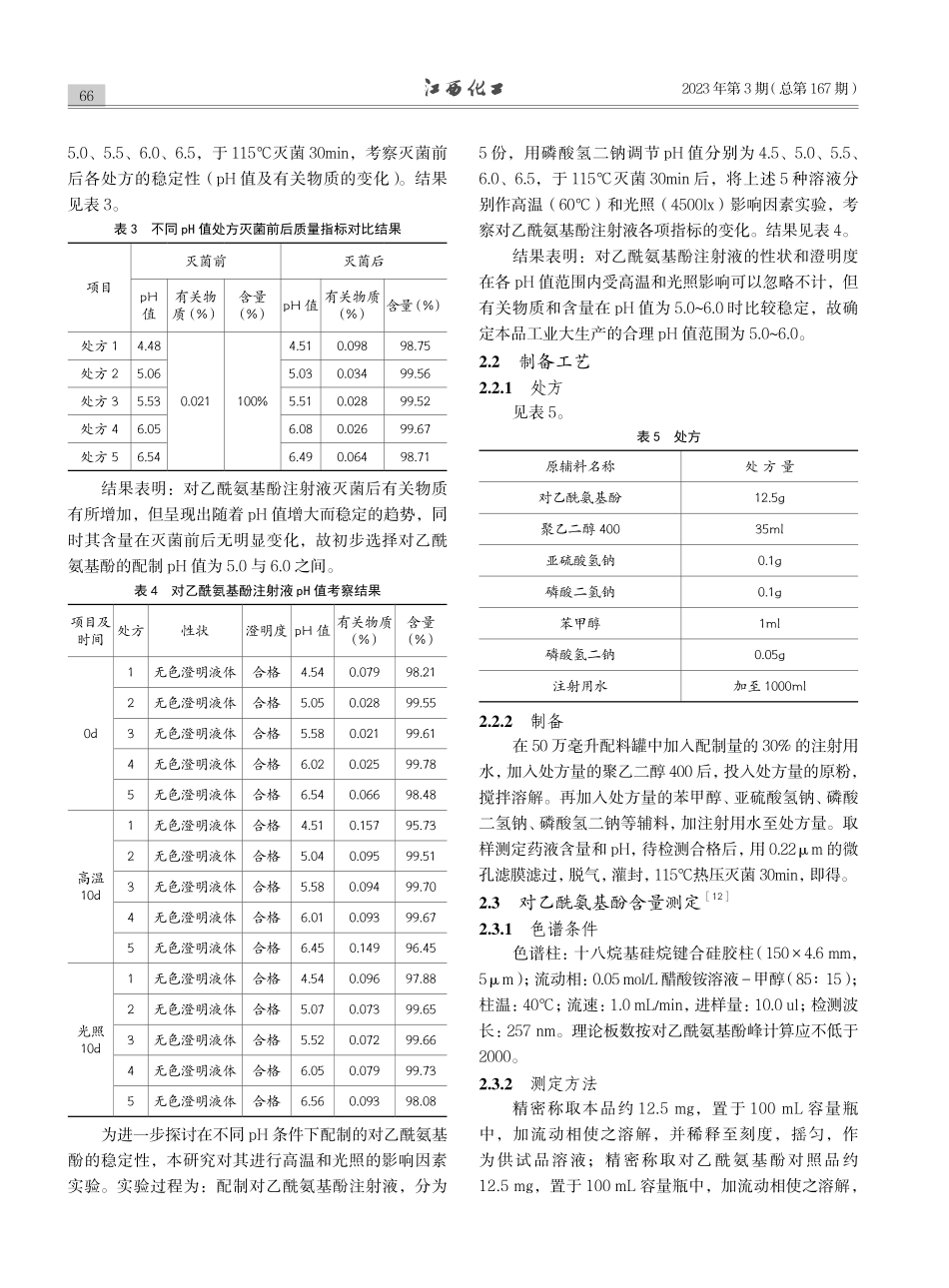

64·分析与应用·2023年第3期(总第167期)对乙酰氨基酚注射液大生产工艺研究吴仁德,肖昱,段锋,梁国嫔*(江西省药品检查员中心,江西南昌,330000)摘要:目的:对对乙酰氨基酚注射液的制备工艺和产品常温放置下的稳定性进行研究,制定切实可行的大生产工艺。方法:通过单因素考察确定制剂的搅拌溶解时间,灭菌工艺,最适pH值等,筛选出最优工艺条件,用高效液相色谱法测定其含量,并对在最优工艺条件下生产的成品进行稳定性考察,验证工艺路线的稳定性和可行性。结果:对乙酰氨基酚注射液制备工艺最优条件为搅拌溶解时间为60min,控制产品pH值在5.0与6.0之间,115℃热压灭菌30min,可以成功制得对乙酰氨基酚注射液,产品规格为2ml:0.25g。此产品在常温下密封放置6个月稳定性良好。结论:优化后的对乙酰氨基酚注射液生产工艺稳定可行,成品质量稳定可控,适用于工业化大生产。关键词:对乙酰氨基酚注射液;大生产工艺;稳定性中图分类号:TQ463文献标志码:A文章编号:1008-3103(2023)03-0064-04StudyontheProductionProcessofAcetaminophenInjectionWuRen-de,XiaoYu,DuanFeng,LiangGuo-pin*(JiangxiDrugInspectionCenter,NanchangJiangxi330000,China)Abstract:Objective:Tostudythepreparationprocessofacetaminopheninjectionandthestabilityoftheproductatroomtemperature,andtodevelopafeasiblelarge-scaleproductionprocess.Methods:Thestirringdissolutiontime,sterilizationprocessandoptimalpHvalueofthepreparationweredeterminedbysinglefactorinvestigation,andtheoptimalprocessconditionswereselected.Thecontentwasdeterminedbyhighperformanceliquidchromatography.Thestabilityofthefinishedproductproducedundertheoptimalprocessconditionswasinvestigatedtoverifythestabilityandfeasibilityoftheprocessroute.Results:Theoptimalconditionsforthepreparationofacetaminopheninjectionwereasfollows:thestirringdissolutiontimewas60min,thepHvalueoftheproductwascontrolledat5.0~6.0,andthehotpressingsterilizationwas30minat115℃.Theacetaminopheninjectionwassuccessfullyprepared,andtheproductspecificationwas2ml:0.25g.Thisproducthasgoodstabilityatroomtemperaturefor6months.Conclusion:Theoptimizedproductionprocessofacetaminopheninjectionisstableandfeasible,andthequalityofth...