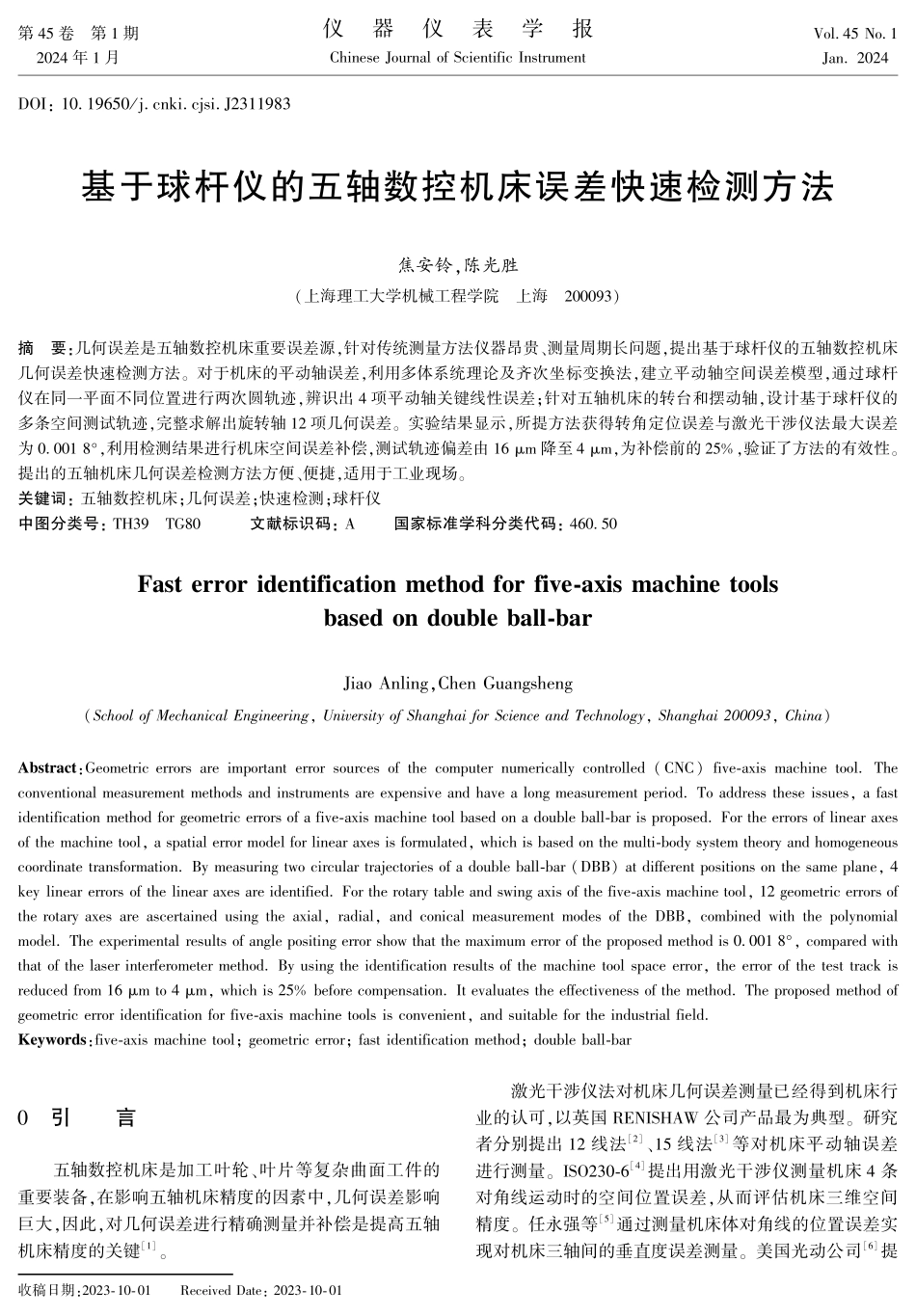

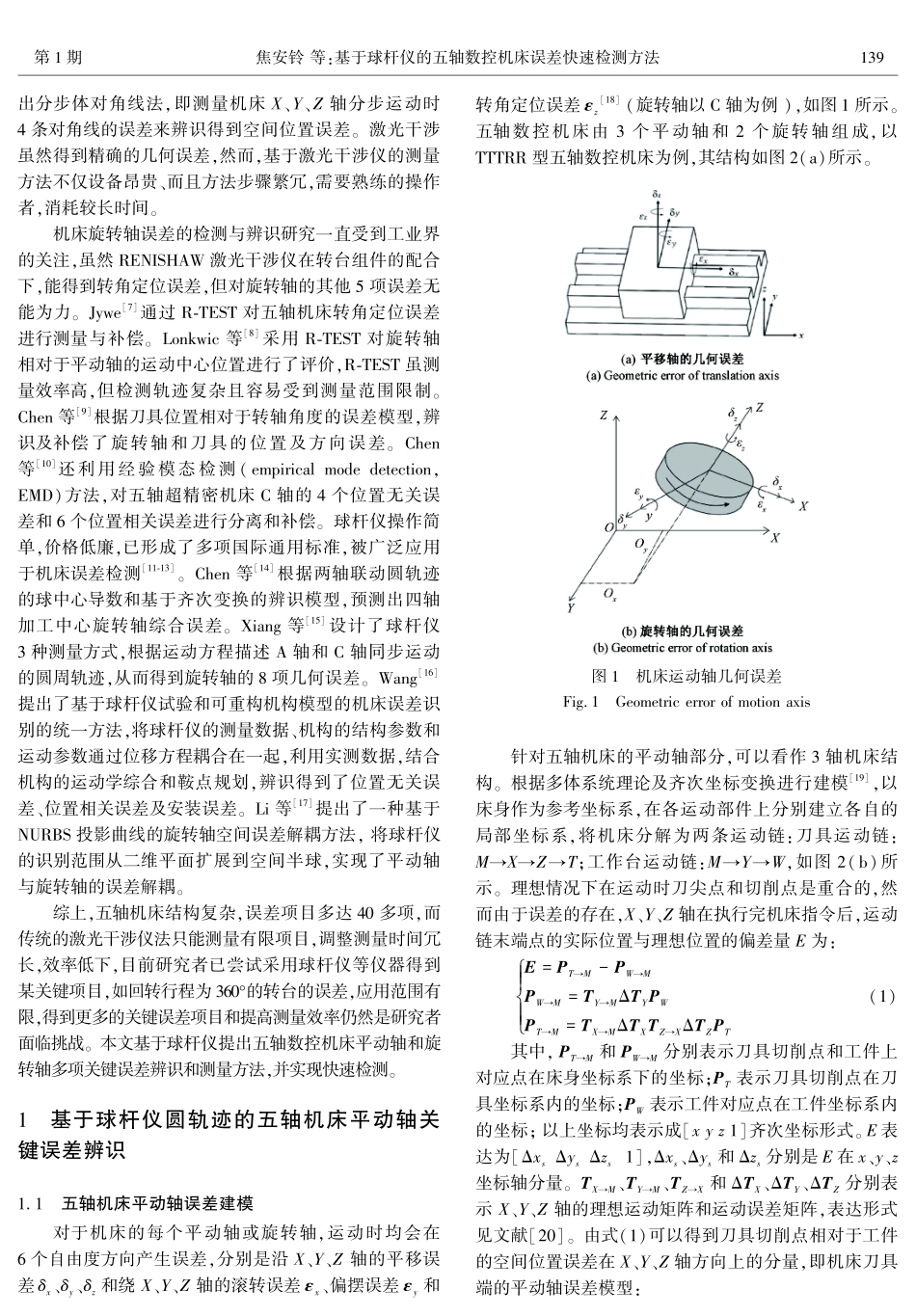

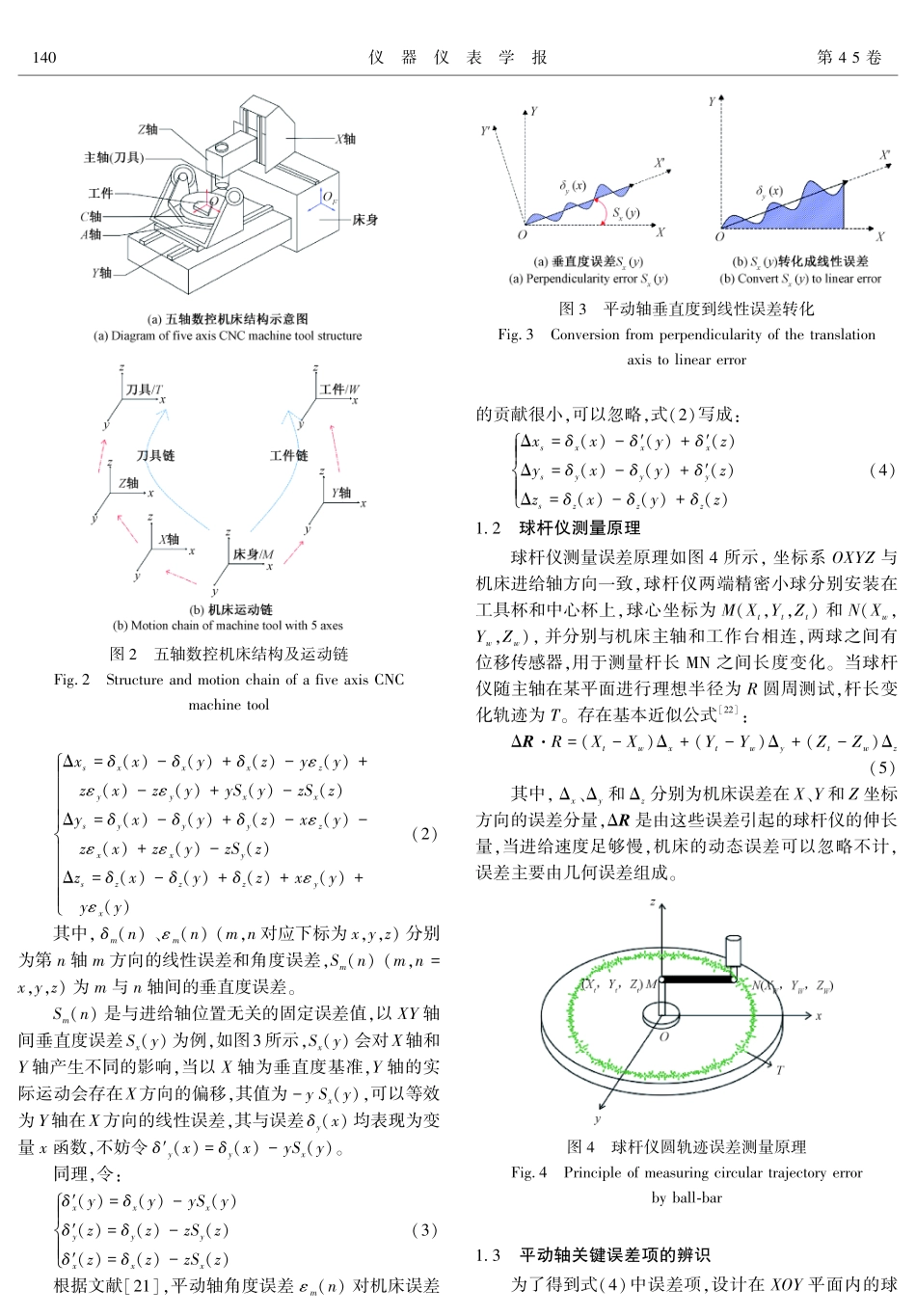

第45卷第1期2024年1月仪器仪表学报ChineseJournalofScientificInstrumentVol.45No.1Jan.2024DOI:10.19650/j.cnki.cjsi.J2311983收稿日期:2023-10-01ReceivedDate:2023-10-01基于球杆仪的五轴数控机床误差快速检测方法焦安铃,陈光胜(上海理工大学机械工程学院上海200093)摘要:几何误差是五轴数控机床重要误差源,针对传统测量方法仪器昂贵、测量周期长问题,提出基于球杆仪的五轴数控机床几何误差快速检测方法。对于机床的平动轴误差,利用多体系统理论及齐次坐标变换法,建立平动轴空间误差模型,通过球杆仪在同一平面不同位置进行两次圆轨迹,辨识出4项平动轴关键线性误差;针对五轴机床的转台和摆动轴,设计基于球杆仪的多条空间测试轨迹,完整求解出旋转轴12项几何误差。实验结果显示,所提方法获得转角定位误差与激光干涉仪法最大误差为0.0018°,利用检测结果进行机床空间误差补偿,测试轨迹偏差由16μm降至4μm,为补偿前的25%,验证了方法的有效性。提出的五轴机床几何误差检测方法方便、便捷,适用于工业现场。关键词:五轴数控机床;几何误差;快速检测;球杆仪中图分类号:TH39TG80文献标识码:A国家标准学科分类代码:460.50Fasterroridentificationmethodforfive-axismachinetoolsbasedondoubleball-barJiaoAnling,ChenGuangsheng(SchoolofMechanicalEngineering,UniversityofShanghaiforScienceandTechnology,Shanghai200093,China)Abstract:Geometricerrorsareimportanterrorsourcesofthecomputernumericallycontrolled(CNC)five-axismachinetool.Theconventionalmeasurementmethodsandinstrumentsareexpensiveandhavealongmeasurementperiod.Toaddresstheseissues,afastidentificationmethodforgeometricerrorsofafive-axismachinetoolbasedonadoubleball-barisproposed.Fortheerrorsoflinearaxesofthemachinetool,aspatialerrormodelforlinearaxesisformulated,whichisbasedonthemulti-bodysystemtheoryandhomogeneouscoordinatetransformation.Bymeasuringtwocirculartrajectoriesofadoubleball-bar(DBB)atdifferentpositionsonthesameplane,4keylinearerrorsofthelinearaxesareidentified.Fortherotarytableandswingaxisofthefive-axismachinetool,12geometricerrorsoftherotaryaxesareascertainedusingtheaxial,radial,andconicalmeasurementmodesoftheDBB,combinedwiththepolynomialmodel.Theexperimentalresultsofanglepositingerrorshowthatthemaxi...