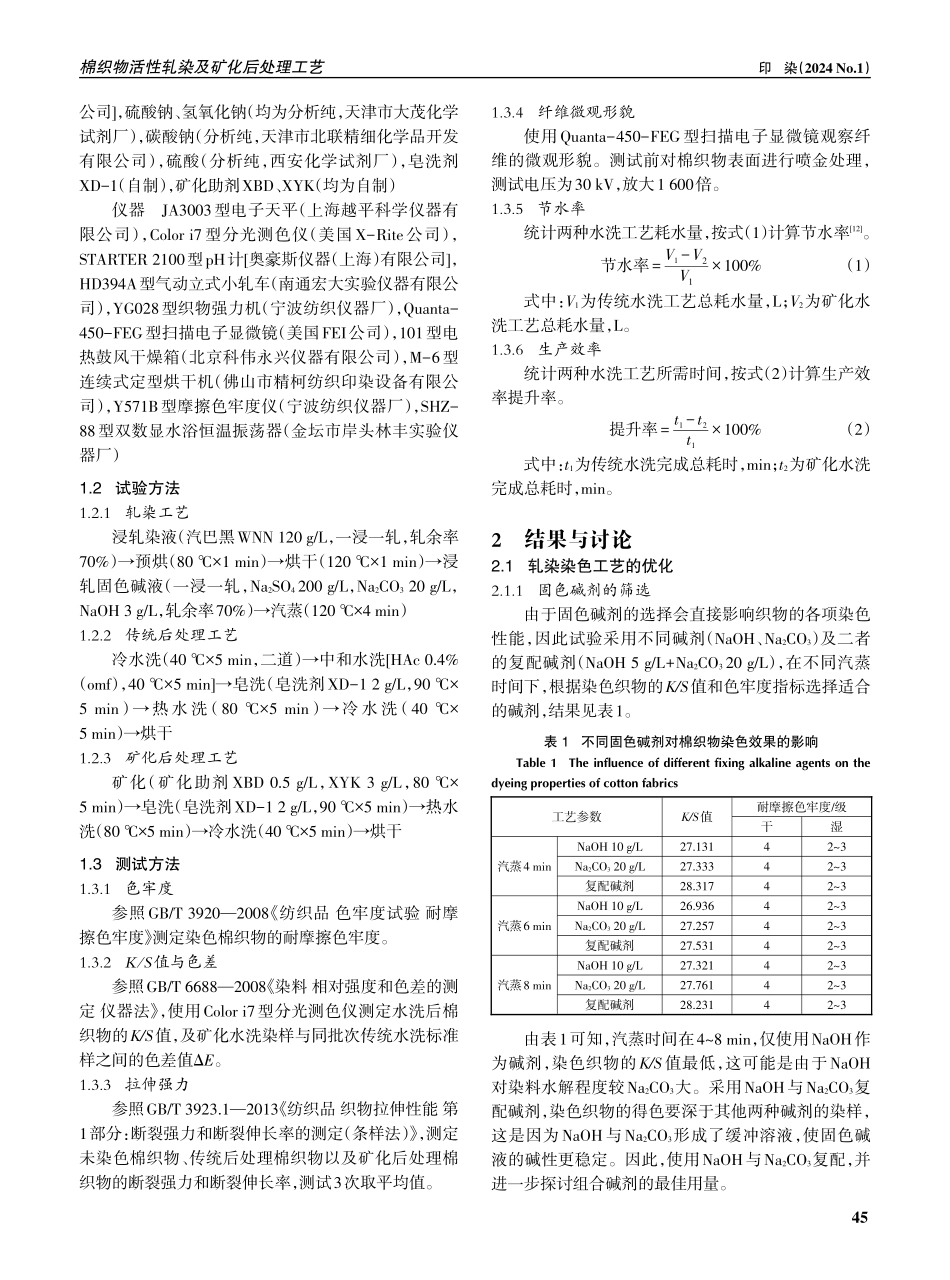

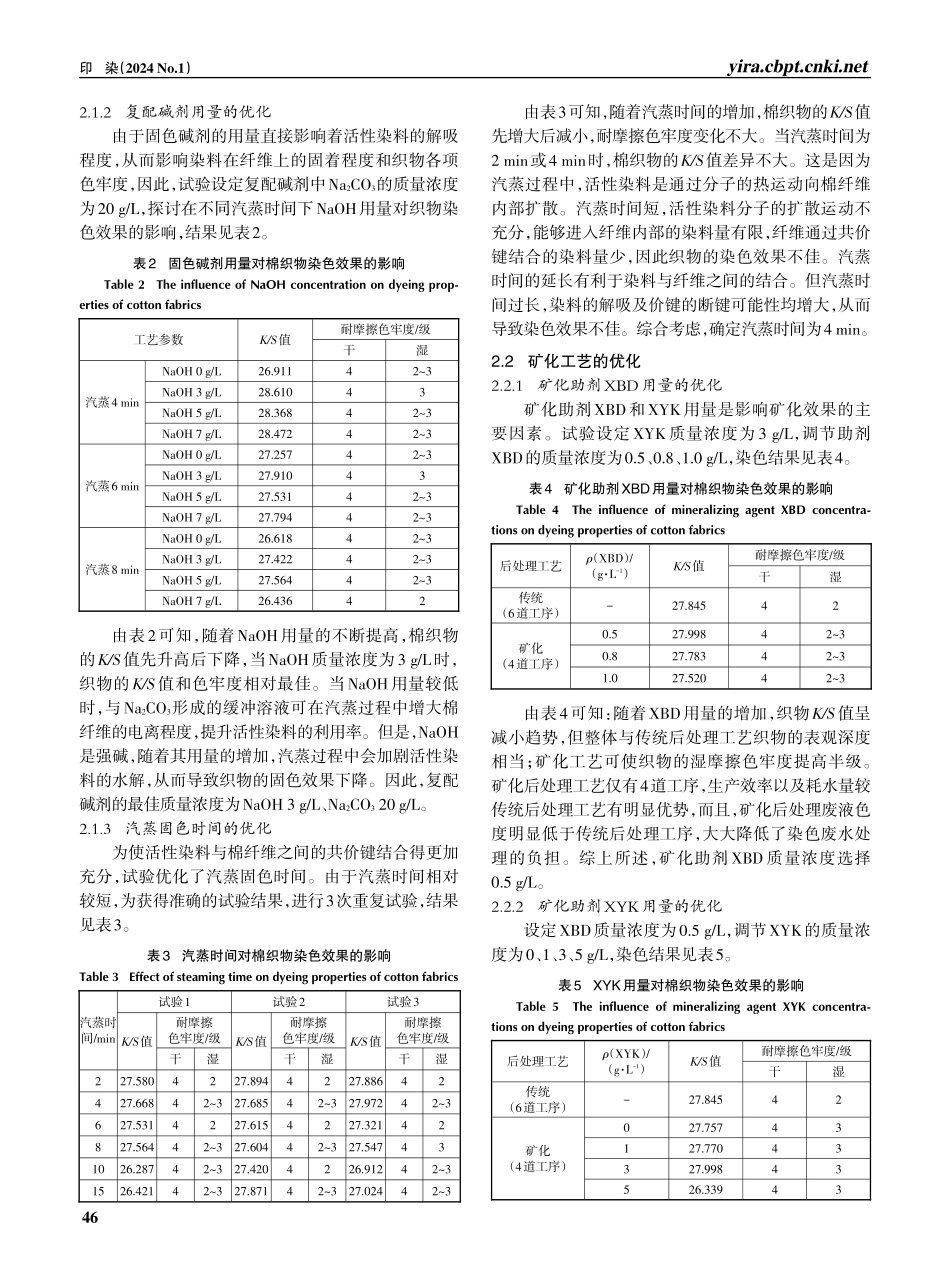

印染(2024No.1)yira.cbpt.cnki.net棉织物活性轧染及矿化后处理工艺王高阳,任燕,席世海,王化东,徐成书()西安工程大学纺织科学与工程学院,陕西西安710048摘要:为实现印染加工环节的节水减排,将棉织物活性染料轧染后采用矿化工艺后处理,探讨了染色工艺中固色碱剂种类、用量和矿化后处理工艺中助剂XBD、XYK用量等因素对织物染色性能的影响。结果表明:在复配碱剂Na2CO320g/L+NaOH3g/L、汽蒸温度120℃、汽蒸时间4min条件下,棉织物可获得良好的染色效果。矿化后处理工艺(XBD0.5g/L、XYK3g/L、温度80℃)可使织物的色牢度较常规后处理工艺提高半级,染色废水色度明显降低,且由传统的6道工序缩短至4道,节约加工时间33%,节约用水33%,提效节能效果显著。关键词:活性染料;轧染;矿化;节水;棉织物中图分类号:TS193.632文献标志码:BDOI:10.3969/j.yinran.202401003Paddyeingandmineralizationpost-treatmentofcottonfabricwithreactivedyesWANGGaoyang,RENYan,XIShihai,WANGHuadong,XUChengshu()CollegeofTextilesScienceandEngineering,Xi′anPolytechnicUniversity,Xi′an710048,ChinaAbstract:Inordertoachievewaterconservationandemissionreductionintheprintinganddyeingprocess,themineralizationpost-treatmentofcottonfabricsafterpad-dyeingwithreactivedyesiscarriedout.Theeffectsofthetypesandamountsoffixingalkalineagentsinthedyeingprocess,aswellasfactorssuchasadditivesXBDandXYKinthemineralizationprocessonthedyeingpropertiesoffabricsarediscussed.TheresultsshowthatcottonfabricscanachievegooddyeingpropertiesundertheconditionsofacomplexalkalineagentofNa2CO320g/LandNaOH3g/L,steamingat120℃for4min.Themineralizationpost-treatmentprocess(XBD0.5g/L,XYK3g/L,temperature80℃)canimprovethecolorfastnessoffabricsby0.5gradecomparedtothosewithconventionalpost-treatmentprocesses,andshortenthetraditional6stepsto4stepsinprocess.Thepro⁃cesscansaveprocessingtimeby33%andwaterby33%,withsignificantefficiencyandenergysaving.Keywords:reactivedyes;paddyeing;mineralization;watersaving;cottonfabric在棉纤维活性染料轧染过程中,为提高染料的利用率,通常要加入大量的无机盐进行促染,例如染深色时盐的质量浓度可达200~250g/L,而上染率只能达到70%~80%[1-4]。在染色后处理环节,未固着...