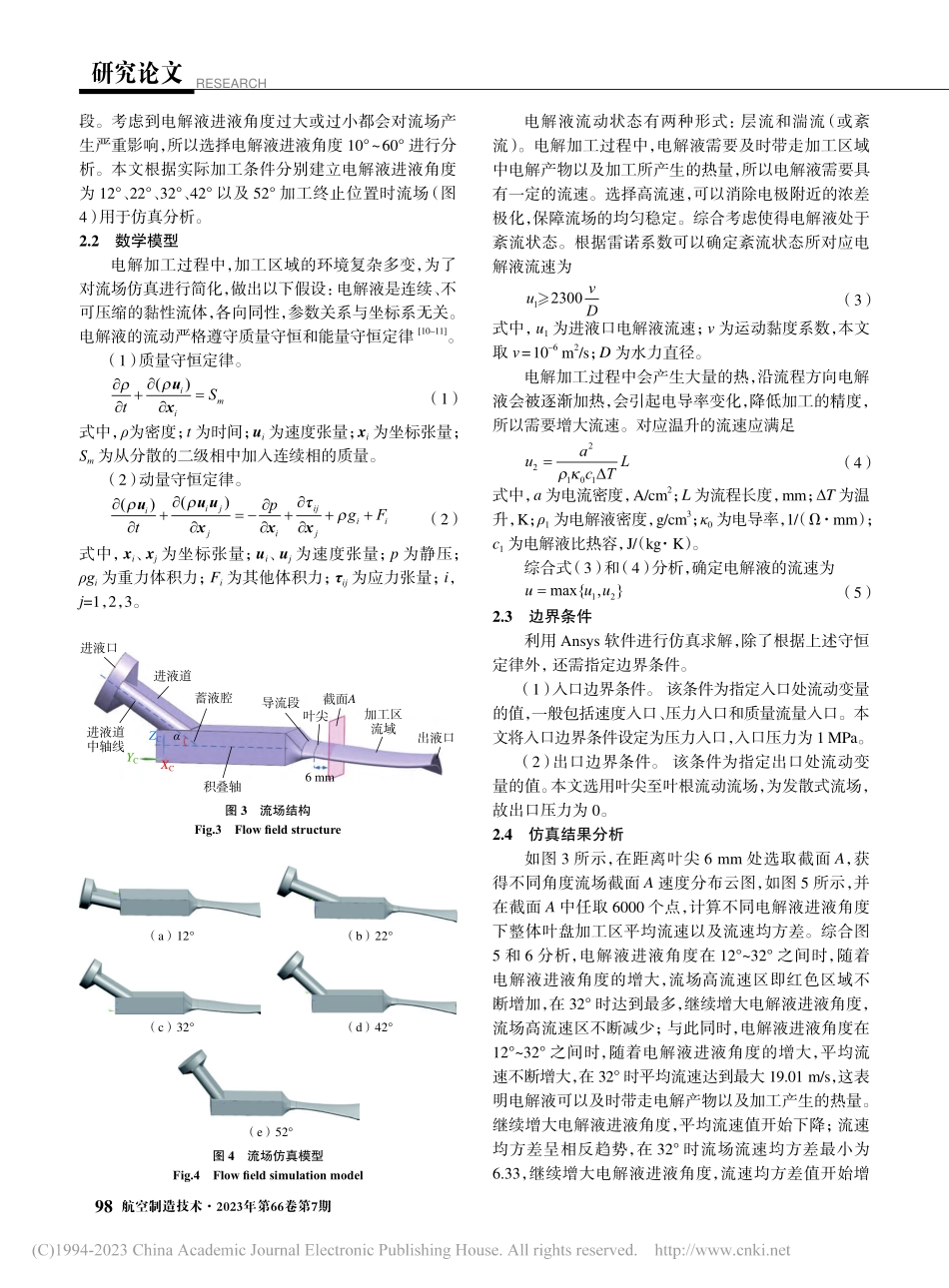

96航空制造技术·2023年第66卷第7期研究论文RESEARCH整体叶盘电解加工电解液进液角度优化研究*侯镇浩1,王京涛1,朱栋1,王福平2,陈文亮2(1.南京航空航天大学,南京210016;2.中国航发动力股份有限公司,西安710021)[摘要]整体叶盘电解加工中,流场对加工稳定性起着重要作用,电解液进液角度对流场均匀性具有重要影响。针对由叶尖至叶根流动模式,设计了5种电解液进液角度流动模型(12°、22°、32°、42°以及52°),并开展电解加工流场仿真研究。结果表明,电解液进液角度为32°时,平均流速为19.01m/s,流速均方差为6.33,满足整体叶盘电解加工对流场的要求。在电解液进液角度为32°的流场形式下,开展整体叶盘电解加工试验,加工过程稳定,试件表面无流纹,加工精度为0.12mm,表面粗糙度为Ra0.353μm,验证了流场的合理性。关键词:电解加工;流场仿真;整体叶盘;加工精度;表面质量OptimizationofElectrolyteSolutionInletAngleforElectrochemicalMachiningofBliskHOUZhenhao1,WANGJingtao1,ZHUDong1,WANGFuping2,CHENWenliang2(1.NanjingUniversityofAeronauticsandAstronautics,Nanjing210016,China;2.AECCAviationPowerCo.,Ltd.,Xi’an710021,China)[ABSTRACT]Intheelectrochemicalmachining(ECM)oftheblisk,theflowfieldplaysanimportantroleinthemachiningstability,andtheinletangleofelectrolytesolutionhasanimportantinfluenceontheuniformityoftheflowfield.Fortheflowpatternfrombladetiptobladeroot,fiveinletangleflowmodels(12°,22°,32°,42°and52°)weredesigned,andtheflowfieldsimulationofelectrochemicalmachiningwascarriedout.Theresultsshowthattheaverageflowrateis19.01m/sandthemeansquaredeviationofflowrateis6.33whentheinletangleofelectrolyteis32°,whichmeetstherequirementsofflowfieldforelectrochemicalmachiningoftheblisk.Undertheflowfieldformwithinletangleofelectrolytesolutionof32°,theelectrochemicalmachiningexperimentofthebliskwascarriedout.Themachiningprocesswasstable,thesurfaceoftheworkpiecewasfreeofflowtexture,themachiningaccuracywas0.12mm,andthesurfaceroughnesswasRa0.353µm,whichverifiedtherationalityoftheflowfield.Keywords:Electrochemicalmachining;Flowfield;Blisk;Machiningaccuracy;SurfacequalityDOI:10.16080/j.issn1671-833x.2023.07.096*基金项目:...