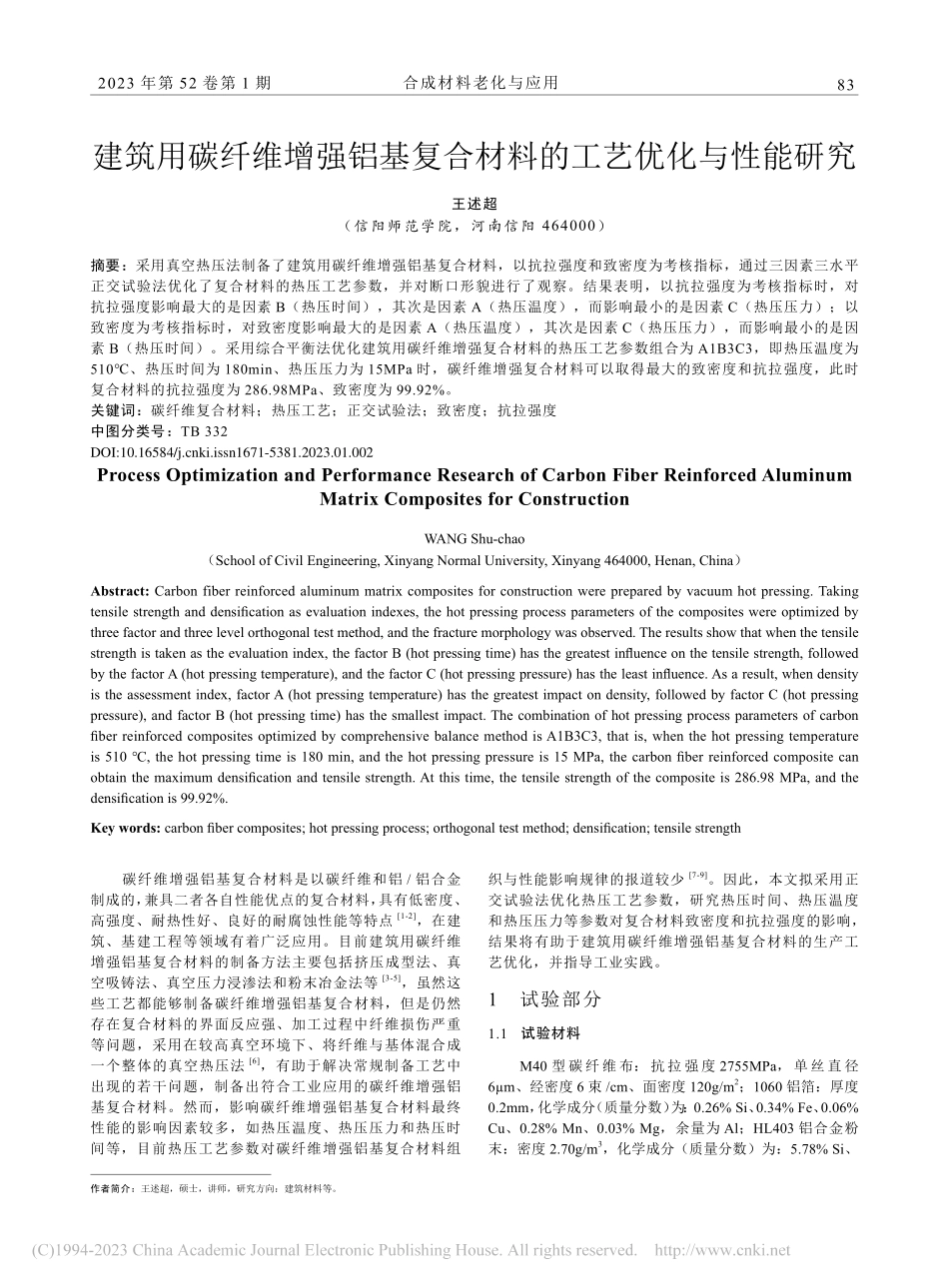

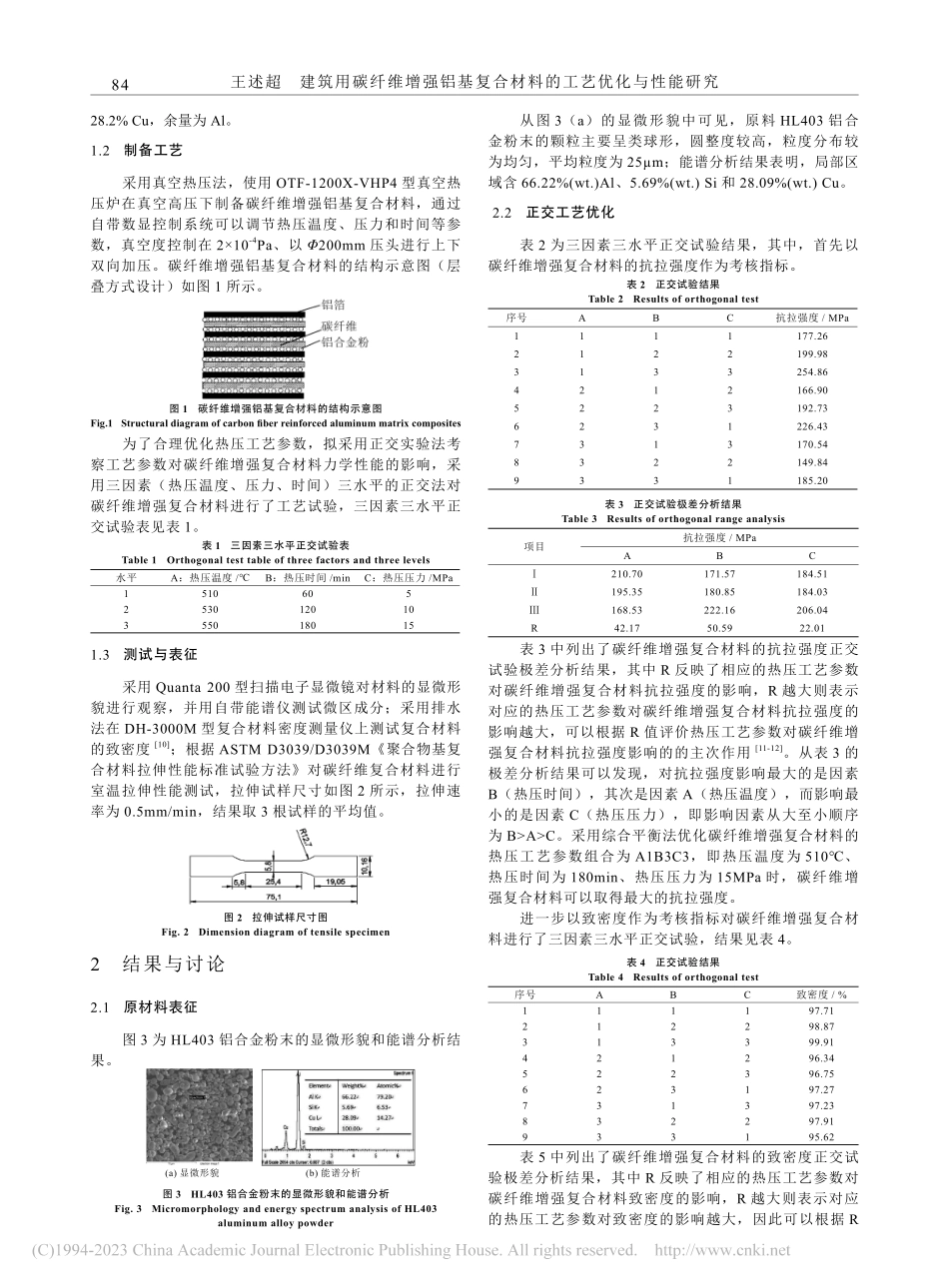

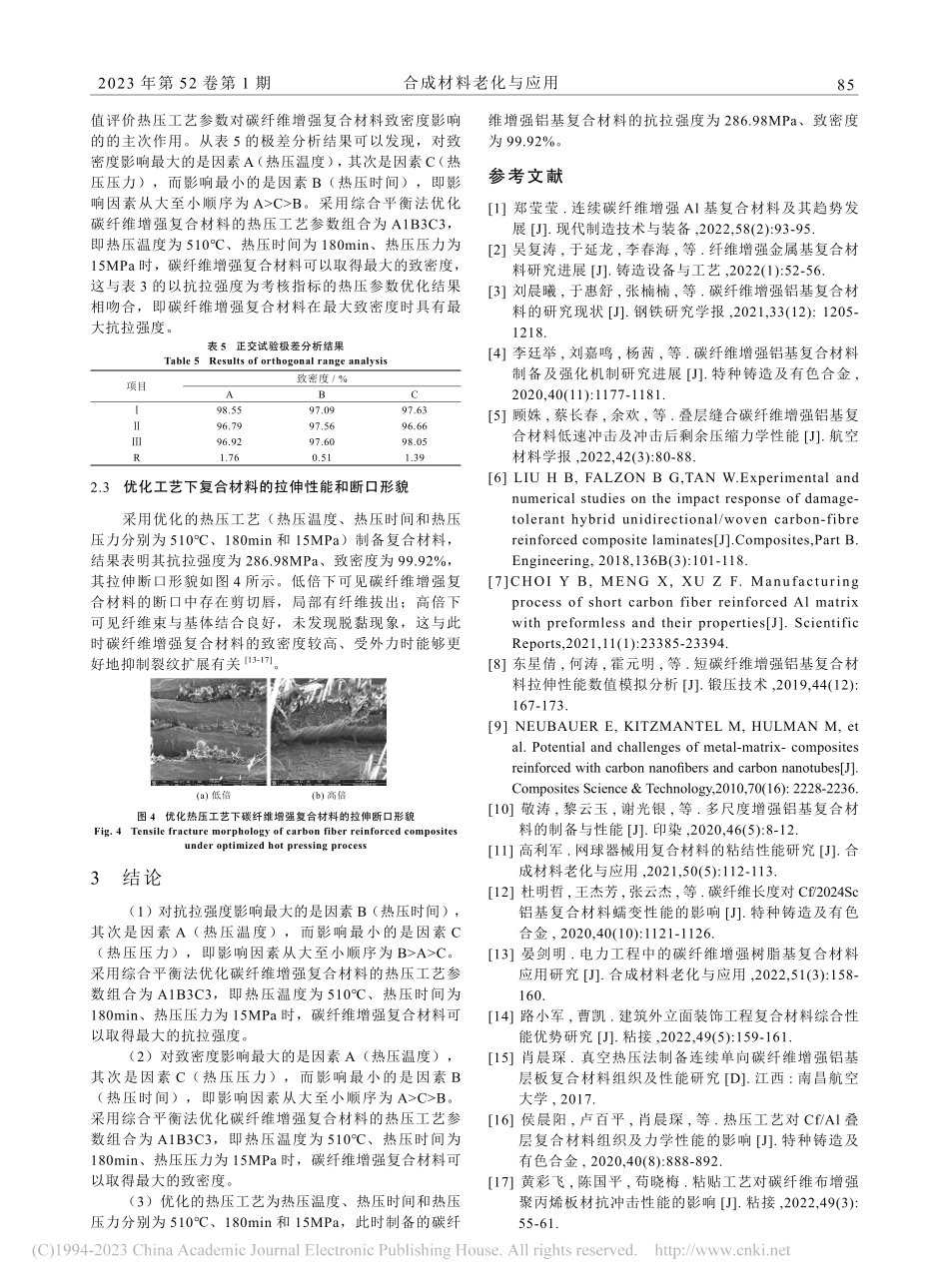

合成材料老化与应用2023年第52卷第1期83建筑用碳纤维增强铝基复合材料的工艺优化与性能研究王述超(信阳师范学院,河南信阳464000)摘要:采用真空热压法制备了建筑用碳纤维增强铝基复合材料,以抗拉强度和致密度为考核指标,通过三因素三水平正交试验法优化了复合材料的热压工艺参数,并对断口形貌进行了观察。结果表明,以抗拉强度为考核指标时,对抗拉强度影响最大的是因素B(热压时间),其次是因素A(热压温度),而影响最小的是因素C(热压压力);以致密度为考核指标时,对致密度影响最大的是因素A(热压温度),其次是因素C(热压压力),而影响最小的是因素B(热压时间)。采用综合平衡法优化建筑用碳纤维增强复合材料的热压工艺参数组合为A1B3C3,即热压温度为510℃、热压时间为180min、热压压力为15MPa时,碳纤维增强复合材料可以取得最大的致密度和抗拉强度,此时复合材料的抗拉强度为286.98MPa、致密度为99.92%。关键词:碳纤维复合材料;热压工艺;正交试验法;致密度;抗拉强度中图分类号:TB332ProcessOptimizationandPerformanceResearchofCarbonFiberReinforcedAluminumMatrixCompositesforConstructionWANGShu-chao(SchoolofCivilEngineering,XinyangNormalUniversity,Xinyang464000,Henan,China)Abstract:Carbonfiberreinforcedaluminummatrixcompositesforconstructionwerepreparedbyvacuumhotpressing.Takingtensilestrengthanddensificationasevaluationindexes,thehotpressingprocessparametersofthecompositeswereoptimizedbythreefactorandthreelevelorthogonaltestmethod,andthefracturemorphologywasobserved.Theresultsshowthatwhenthetensilestrengthistakenastheevaluationindex,thefactorB(hotpressingtime)hasthegreatestinfluenceonthetensilestrength,followedbythefactorA(hotpressingtemperature),andthefactorC(hotpressingpressure)hastheleastinfluence.Asaresult,whendensityistheassessmentindex,factorA(hotpressingtemperature)hasthegreatestimpactondensity,followedbyfactorC(hotpressingpressure),andfactorB(hotpressingtime)hasthesmallestimpact.ThecombinationofhotpressingprocessparametersofcarbonfiberreinforcedcompositesoptimizedbycomprehensivebalancemethodisA1B3C3,thatis,whenthehotpressingtemperatureis510℃,thehotpressingtimeis180min,andthehotpressingpressureis15MPa,t...