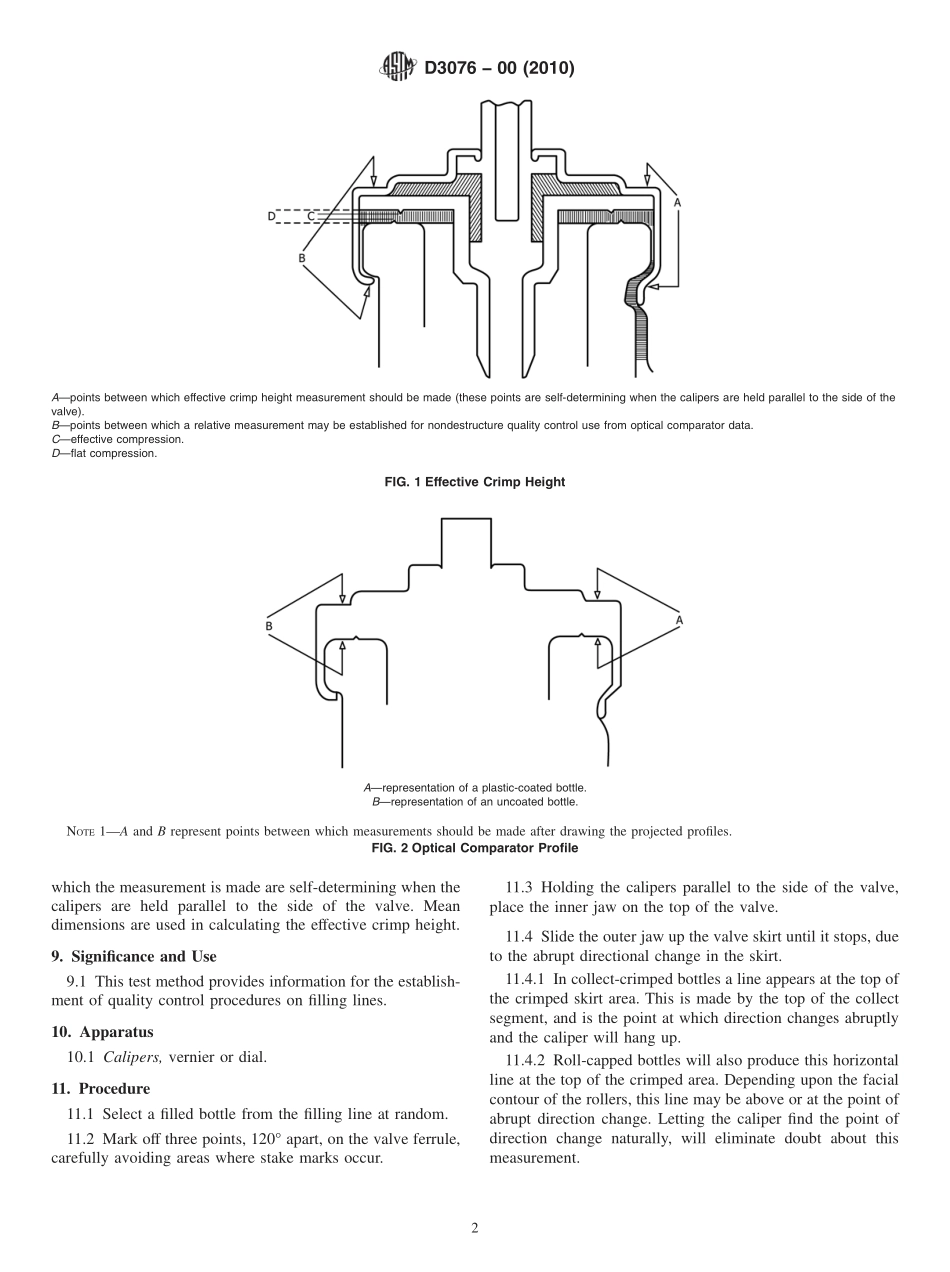

Designation:D3076−00(Reapproved2010)StandardTestMethodsforEffectiveCrimpingonOutsideCrimpedValvesofAerosolContainers1ThisstandardisissuedunderthefixeddesignationD3076;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscovertheeffectivecrimpingonoutsidecrimpedvalveswithinthewideparametersofcontain-ersandvalvesavailable.1.2Thetestmethodsappearinthefollowingorder:SectionsOpticalComparatorTestMethod4to7CaliperTestMethod8to121.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D996TerminologyofPackagingandDistributionEnviron-mentsD3064TerminologyRelatingToAerosolProducts3.Terminology3.1Generaldefinitionsforpackaginganddistributionenvi-ronmentsarefoundinTerminologyD996.3.2GeneraldefinitionsoftermsrelatingtoaerosolproductsarefoundinD3064.OPTICALCOMPARATORTESTMETHOD4.SummaryofTestMethod4.1Thistestmethodinvolvesdrawingaprojected,enlargedprofileofthecontainerandvalve,thenremovingthevalveanddrawingtheprojectedprofileofthecontainerfinish.Measuringtheresultantvoidandsubtractingthedimensionsoftheessentiallynoncompressedcomponentsfromthisvalueresultsinthevaluerepresentingthecompressedthicknessofthevalvesealinggasket.5.SignificanceandUse5.1Thistestmethodprovidesinformationfortheestablish-mentofqualitycontrolproceduresonfillinglines.6.Apparatus6.1OpticalComparator.6.2ClampingJig,fastenedtothecomparatorbench.6.3Grinder,electric,smallenoughtobehandheld.7.Procedure7.1Crimpavalveonanemptybottlewiththelinecrimpersetatnormaloperati...