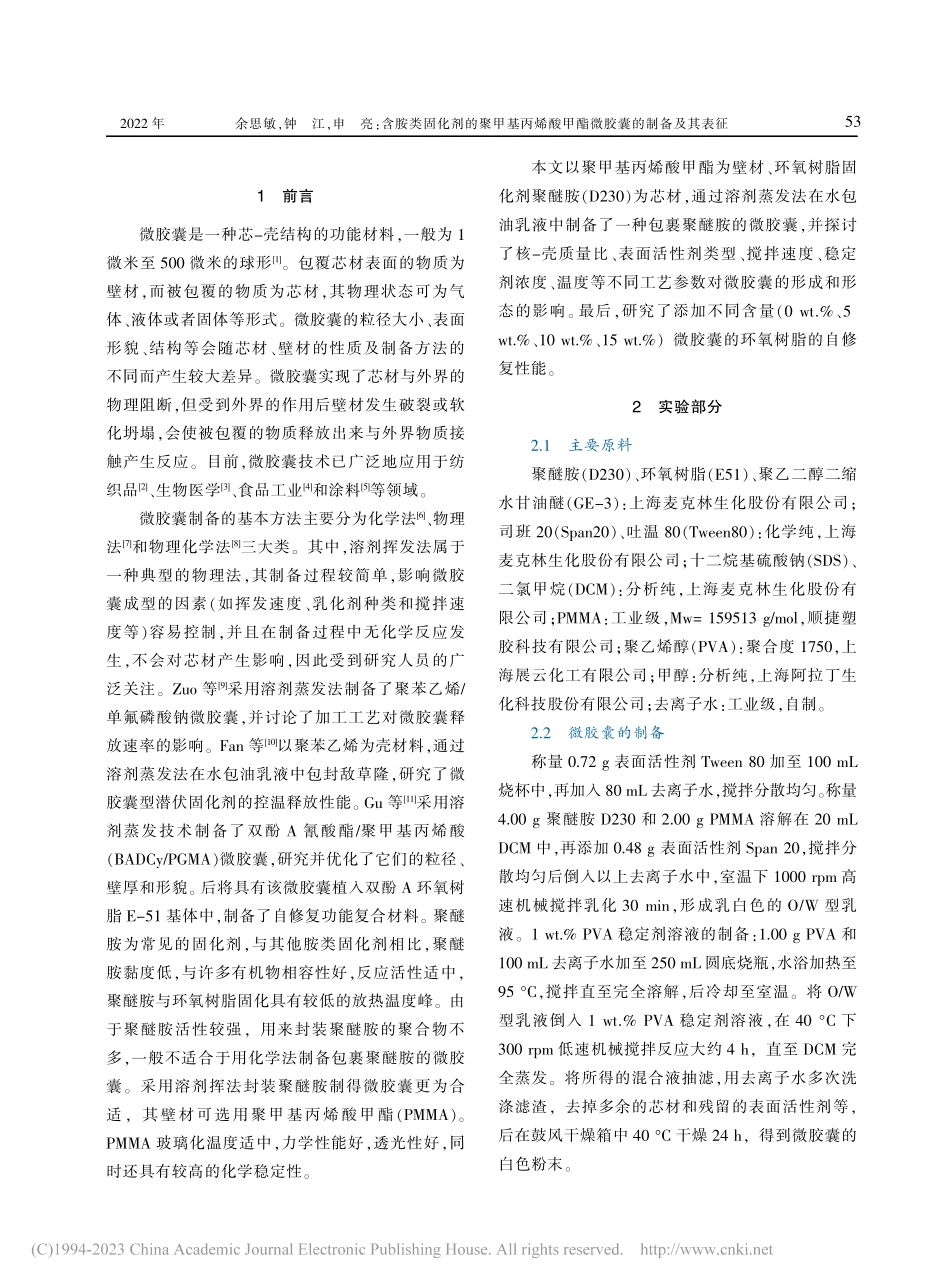

摘要:本文以固化剂聚醚胺(D230)为芯材,聚甲基丙烯酸甲酯(PMMA)为壳材,采用溶剂挥发法制备了包裹胺类固化剂的微胶囊,并研究了芯-壳质量比、表面活性剂类型、搅拌速度、温度、稳定剂浓度等不同因素对微胶囊平均粒径和芯材含量的影响。同时,采用傅里叶变换红外(FTIR)、光学显微镜、差示扫描量热法(DSC)和热重分析(TGA)等对微胶囊的化学结构、形貌及热力学性能进行了表征。实验结果表明:当芯-壳质量比为2:1~4:1、采用复合型表面活性剂、温度为40°C、搅拌速度为1000rpm、稳定剂浓度为2wt%时,制备的微胶囊较理想。将该微胶囊加入环氧树脂中可制得外援型自修复环氧材料。随着微胶囊添加量的增加,损伤样品膜表面的裂纹自修复效果逐渐明显。当添加量为10wt%时,复合材料具有较好的自修复性能。关键词:微胶囊;固化剂;环氧树脂;聚甲基丙烯酸甲酯;自修复中图分类号:O631.5文献标志码:A文章编号:2096-854X(2022)06-0052-08PreparationandCharacterizationofPolymethylMethacrylateMicrocapsulesContainingAmineCuringAgentsYuSimin1,2,ZhongJiang1,2,*,ShenLiang1,2,*(1.DepartmentofCoatingsandPolymericMaterials,SchoolofChemicalEngineering,JiangxiScienceandTechnologyNormalUniversity,Nanchang33013,Jiangxi,P.R.China;2.JiangxiEngineeringLaboratoryofWaterborneCoating,Nanchang330013,Jiangxi,P.R.China)Abstract:Inthispaper,aseriesofmicrocapsulescontainingaminecuringagentswaspreparedbythesolventvolatilizationmethodwithpolyetheramine(D230)ascorematerialandpolymethylmethacrylate(PMMA)asshellmaterial.Theinfluenceofdifferentfactors,suchasthecoreshellmassratio,thetypesofsurfactant,stirringspeed,temperature,andconcentrationofstabilizers,ontheaverageparticlesizeandcorematerialcontentofthemicrocapsuleswassystematicallystudied.Meanwhile,Fouriertransforminfrared(FTIR),opticalmicroscopy,differentialscanningcalorimetry(DSC),dynamicmechanicalanalysis(DMA)andthermogravimetricanalysis(TGA)werealsousedtocharacterizethechemicalstructure,morphologyandthermodynamicpropertiesofthemicrocapsules.Theexperimentalresultsshowthatwhenthecore-shellmassratiowas2:1-4:1,theoptimalmicrocapsulescouldbeobtainedwiththeemploymentofcompoundsurfactantat...