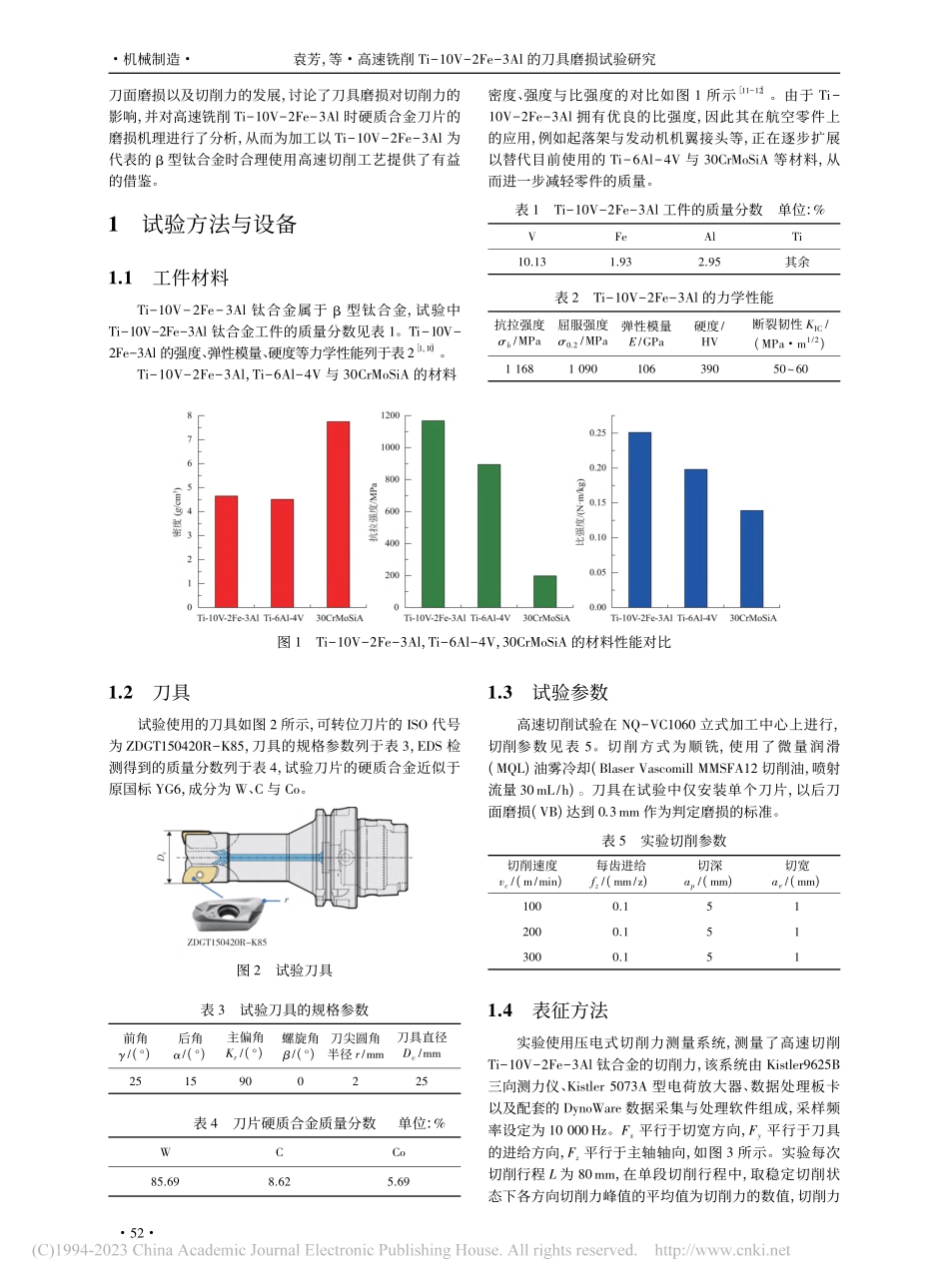

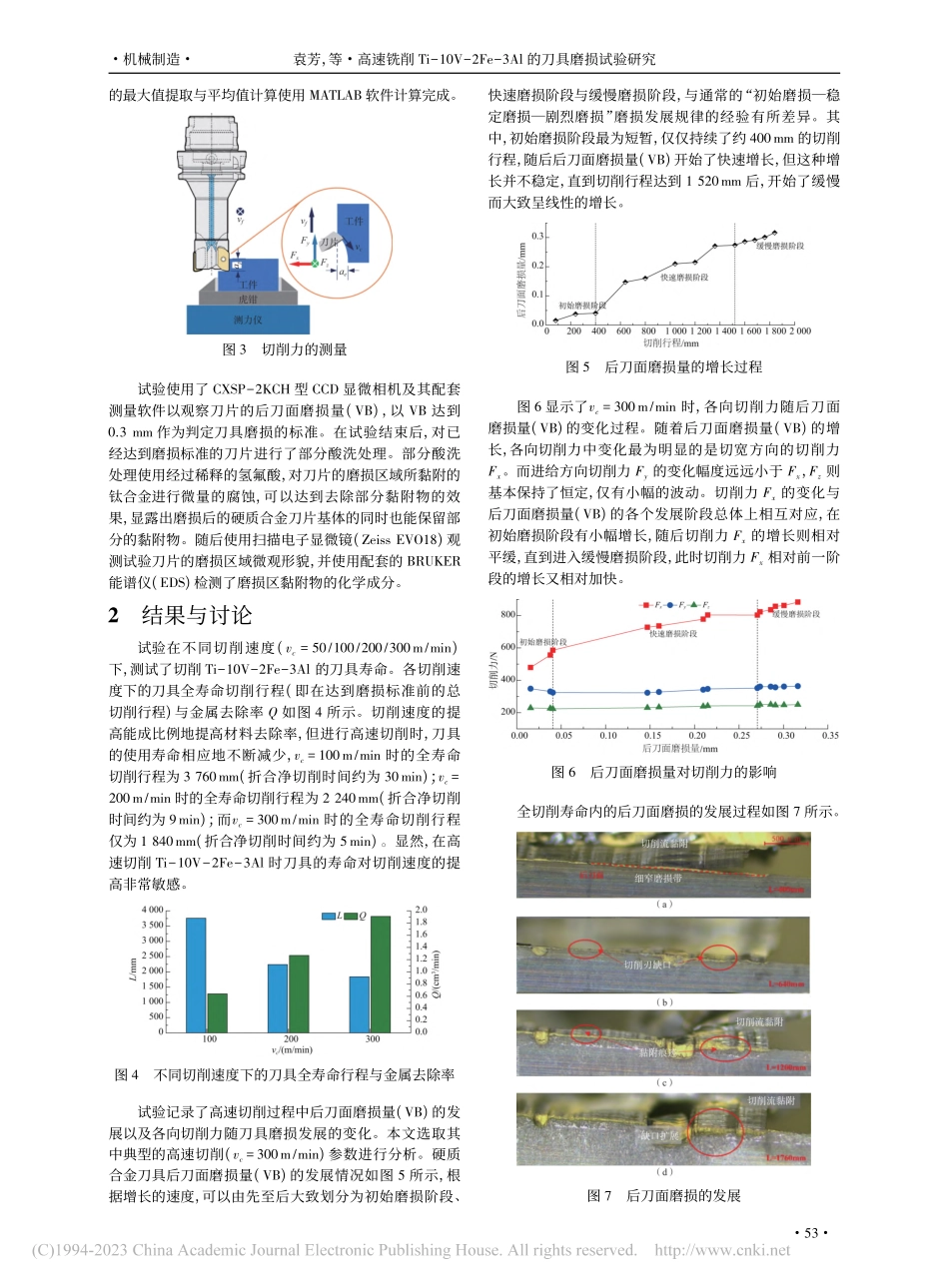

·机械制造·袁芳,等·高速铣削Ti-10V-2Fe-3Al的刀具磨损试验研究第一作者简介:袁芳(1982—),女,安徽宿州人,工程师,硕士,研究方向为复合材料加工技术研究。DOI:10.19344/j.cnki.issn1671-5276.2023.01.012高速铣削Ti-10V-2Fe-3Al的刀具磨损试验研究袁芳,徐亮,王新永,王凯,陈旭辉,宋楠,韩军,严伟容,王松(航天材料及工艺研究所先进功能复合材料技术重点实验室,北京100076)摘要:针对切削加工Ti-10V-2Fe-3Al钛合金时刀具磨损迅速、加工效率低的问题,开展硬质合金刀具高速铣削Ti-10V-2Fe-3Al的刀具寿命试验,以研究刀具的磨损机理,分析刀面磨损的发展以及对切削力的影响。利用扫描电子显微镜观察了后刀面磨损区域的微观形貌并对元素成分进行了能谱分析。实验结果表明:高速铣削Ti-10V-2Fe-3Al时硬质合金刀具的磨损形式为后刀面带状磨损与局部崩刃,伴有明显的切屑黏附与热裂纹;磨损区域有工件材料的元素向硬质合金内扩散的迹象出现;切屑流的黏附与撕扯导致硬质合金的颗粒脱落,切削刃逐步退化为洼形区域,其与后刀面交界的棱边代替原切削刃进行切削直至剥落。关键词:高速切削;Ti-10V-2Fe-3Al;硬质合金刀具;刀具磨损;切削力中图分类号:TG714文献标志码:B文章编号:1671-5276(2023)01-0051-05ExperimentStudyonToolWearofHigh-speedMillingTi-10V-2Fe-3AlYUANFang,XULiang,WANGXinyong,WANGKai,CHENXuhui,SONGNan,HANJun,YANWeirong,WANGSong(ScienceandTechnologyonAdvancedFunctionalCompositesLaboratory,AerospaceResearchInstituteofMaterials&ProcessingTechnology,Beijing100076,China)Abstract:TosolvetheproblemsofrapidtoolwearandlowprocessingefficiencyofmachiningTi-10V-2Fe-3Alalloy,theexperimentsonthetoollifeofhigh-speedmillingTi-10V-2Fe-3Alwiththecarbideinsertwerecarriedouttostudythetoolwearmechanismandanalyzethedevelopmentofflankwearanditsinfluenceoverthecuttingforce.Thescanningelectronmicroscopewasutilizedtoobservethemicrocosmicmorphologyofthewearregionandmakeenergyspectrumanalysisontheelementcompositions.Theexperimentresultsshowthatintheprocessofhigh-speedmillingTi-10V-2Fe-3Al,carbidetoolwearappearsintheformofflankwearbandandlocaledgechippingatthetoolflankface,accompaniedbyobviouschipadhesionandcombcracks...