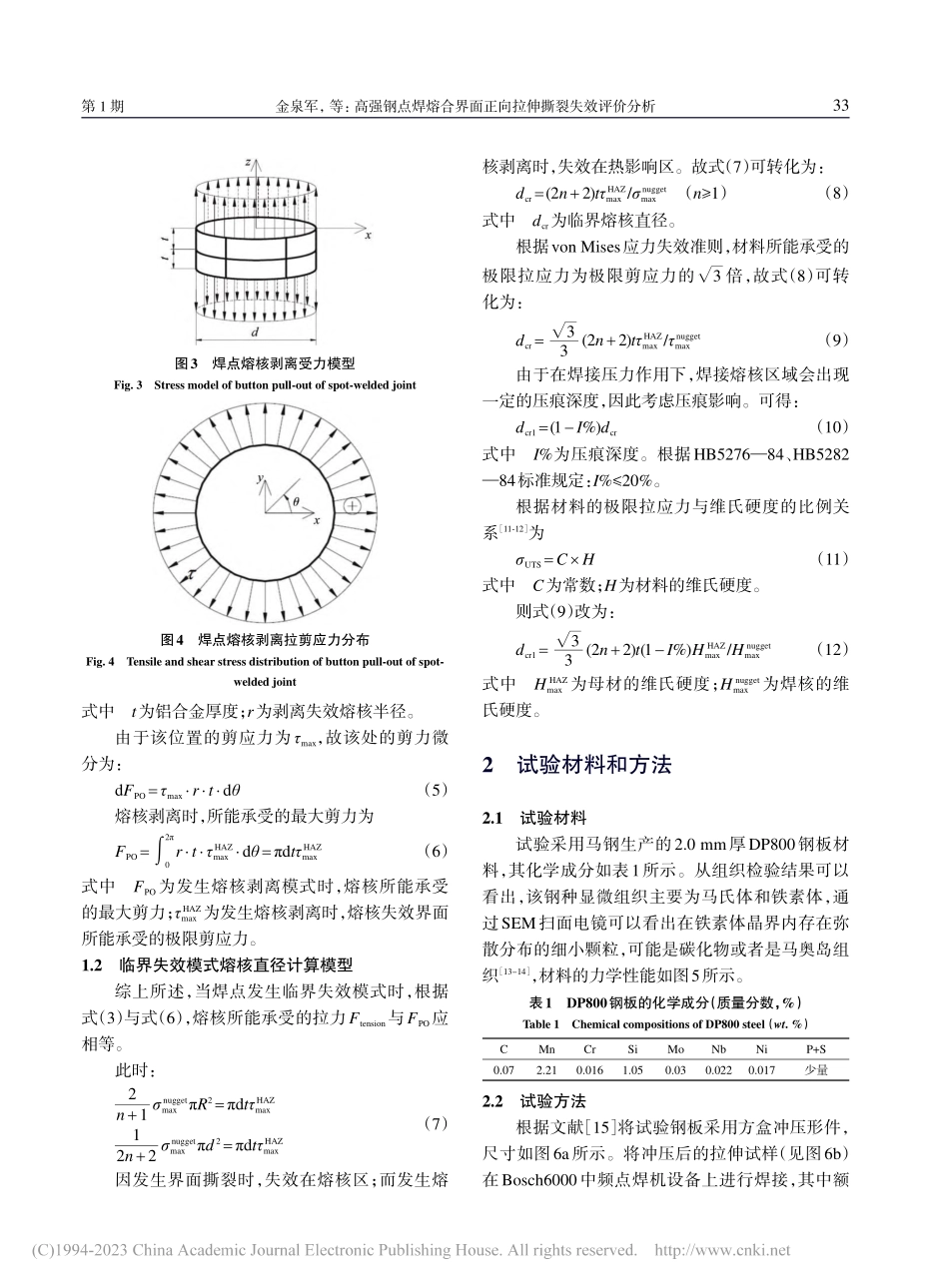

ElectricWeldingMachineVol.53No.1Jan.2023第53卷第1期2023年1月高强钢点焊熔合界面正向拉伸撕裂失效评价分析金泉军,高明,吕玲芳,曾泳浙江吉利远程新能源商用车集团有限公司,浙江杭州311228摘要:基于界面撕裂和熔核剥离两种模式下焊点的不同应力分布规律,通过应用极限应力理论及Mises应力,计算两种失效模式下高强度钢焊点的最大载荷,推导出界面撕裂失效时的临界熔核直径dcr1=(3/3)(2n+2)t(1-I%)HHAZmax/Hnuggetmax。通过正交试验方法对高强钢焊点正向失效模式进行分析验证,结果发现,当实测熔核直径小于临界熔核直径时,焊点发生明显的界面撕裂模式;当实测熔核直径大于临界熔核直径时,发生明显的熔核剥离模式;焊接电流对高强度钢的焊点熔核直径影响最大,对焊点失效方式有较大影响。关键词:高强度钢;界面撕裂;熔核剥离;正向拉伸;失效分析;熔核直径中图分类号:TG457.11文献标识码:A文章编号:1001-2303(2023)01-0031-07FailureAnalysisofFractureofHighStrengthSteelSpot-weldedJointsaboutCrossTensionTestingJINQuanjun,GAOMing,LVLingfang,ZENGYongZhejiangGeelyNewEnergyCommercialVehicleGroudCo.,Ltd.,Hangzhou311228,ChinaAbstract:Accordingtothedifferentstressdistributionunderinterfacialfracturemodeandbuttonpull-outmode,themaxi‐mumforceonhighstrengthsteelspot-weldedjointsfortwokindsoffailuremodeswereanalysisedandcalculatedbasedonMisescriteriaandultimatestresstheory.Thecriticalwelddiameterdcr1=(3/3)(2n+2)t(1-I%)HHAZmax/Hnuggetmaxforinterfacialtearingfailurewascalculated.Highstrengthsteelwasusedtovalidatethecriticalwelddiameterbytheorthogonaltest.Theresultsshowedthatwhenthemeasurednuggetdiameterwassmallerthanthecriticalnuggetdiameter,interfacialfracturemodeappearedintheweldingnugget;whenthemeasurednuggetdiameterwaslargerthanthecriticalnuggetdiameter,but‐tonpull-outmodeappeared.Atthesametime,theweldingcurrenthadthegreatesteffectonthenuggetdiametertoresis‐tancespotweldingofhighstrengthsteel,andithadagreateffectonthefracturemodeofsold-weldedjoints.Keywords:highstrengthsteel;interfacialfracture;buttonpull-out;cross-tensile;failureanalysis;nuggetdiameter引用格式:金泉军,高明,吕玲芳,等.高强钢点焊熔合界面正向拉伸撕裂失效评价...