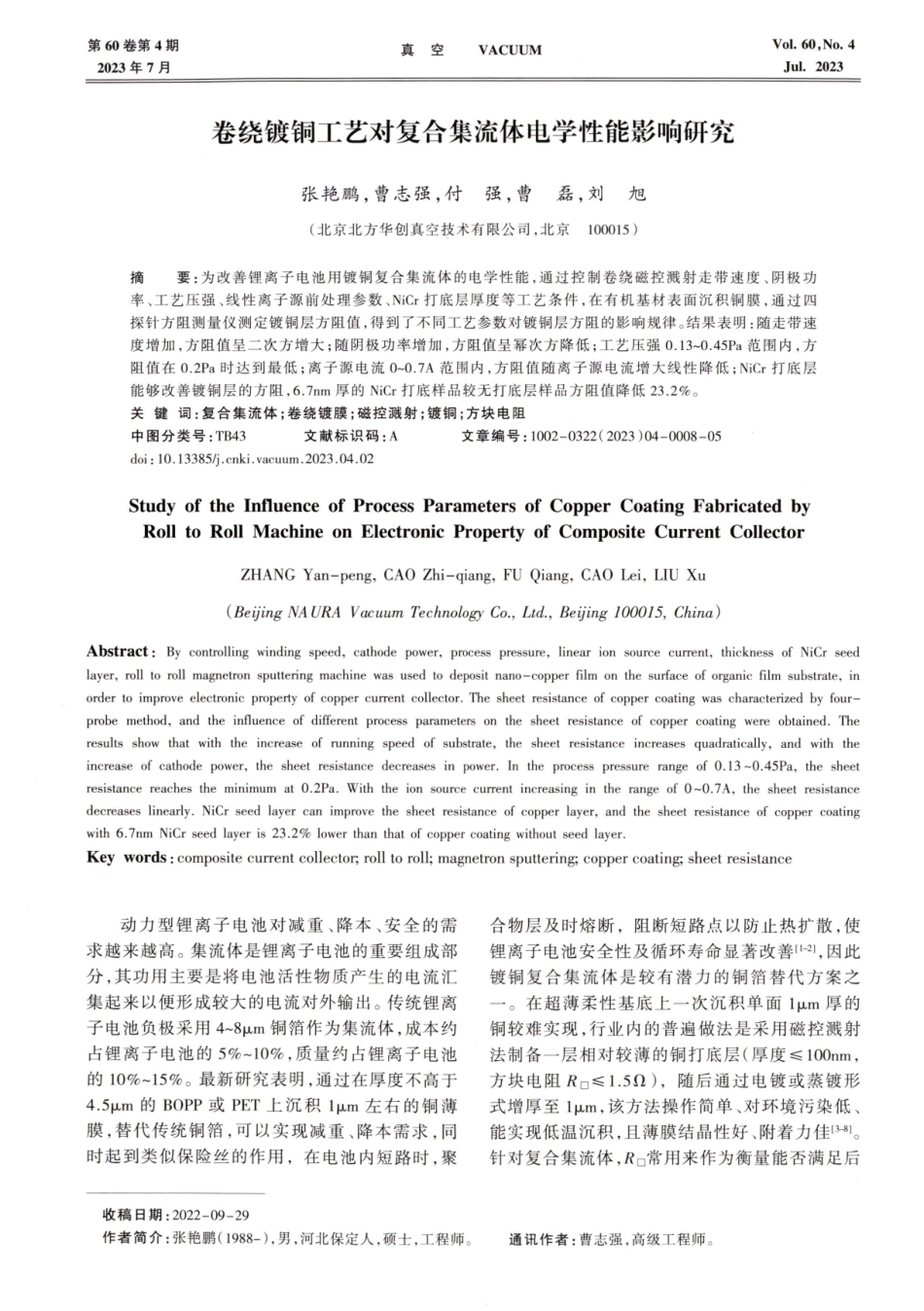

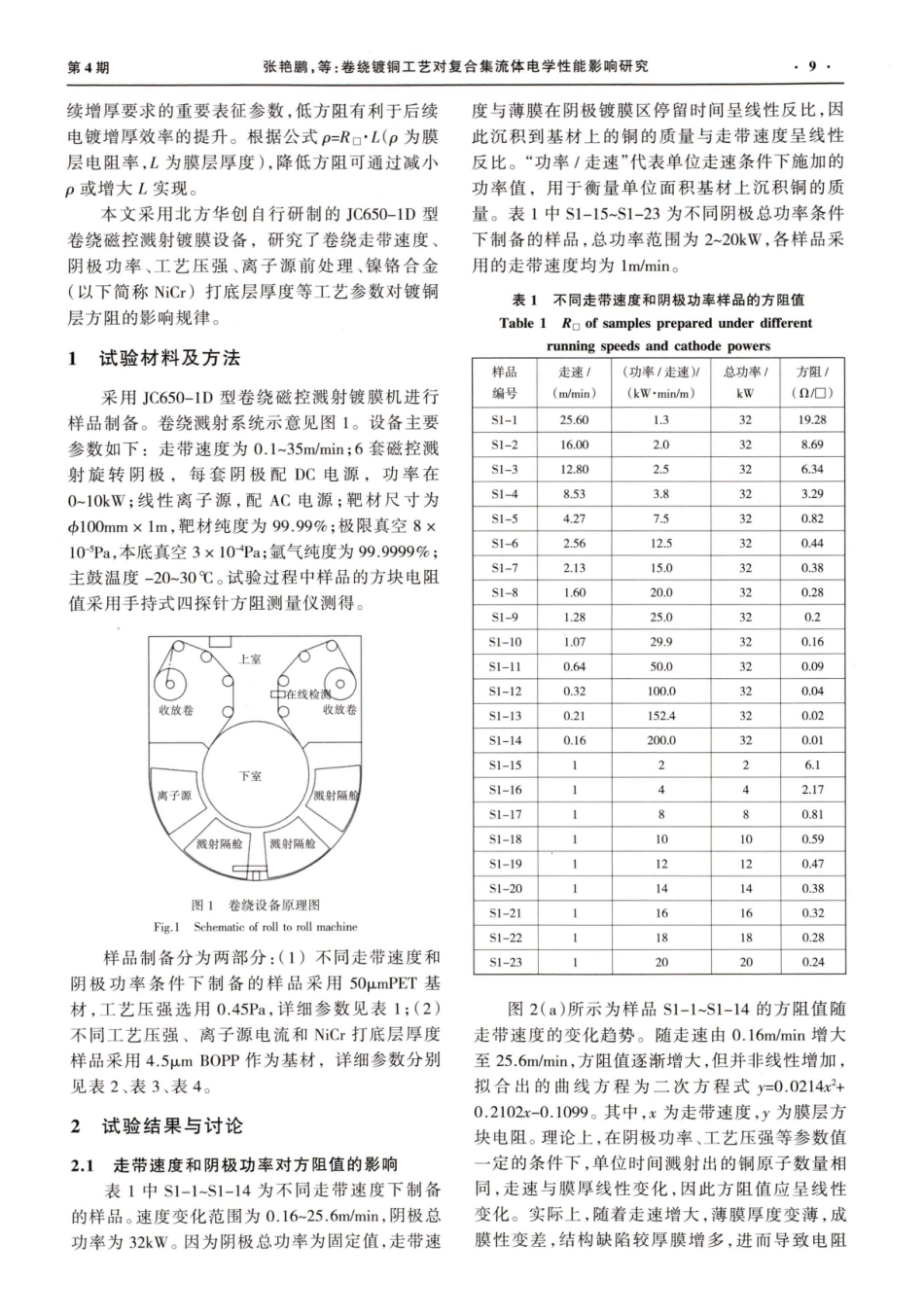

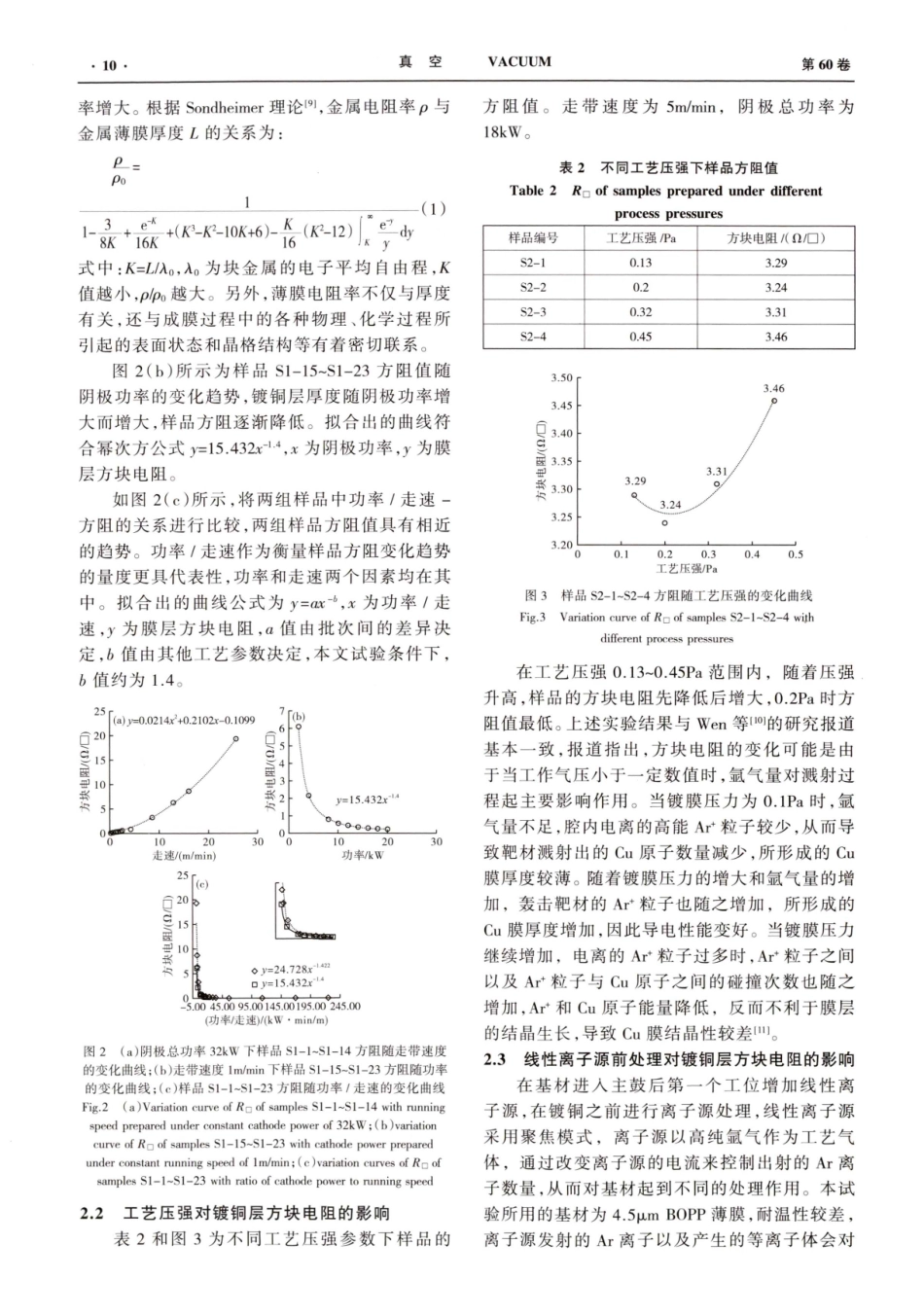

2023年7月Jul.2023VACUUM空真Vol.60,No.4第60卷第4期卷绕镀铜工艺对复合集流体电学性能影响研究张艳鹏,曹志强,付强,曹磊,刘旭(北京北方华创真空技术有限公司,北京100015)摘要:为改善锂离子电池用镀铜复合集流体的电学性能,通过控制卷绕磁控溅射走带速度、阴极功率、工艺压强、线性离子源前处理参数、NiCr打底层厚度等工艺条件,在有机基材表面沉积铜膜,通过四探针方阻测量仪测定镀铜层方阻值,得到了不同工艺参数对镀铜层方阻的影响规律。结果表明:随走带速度增加,方阻值呈二次方增大;随阴极功率增加,方阻值呈幂次方降低;工艺压强0.13~0.45Pa范围内,方阻值在0.2Pa时达到最低;离子源电流0~0.7A范围内,方阻值随离子源电流增大线性降低;NiCr打底层能够改善镀铜层的方阻,6.7nm厚的NiCr打底样品较无打底层样品方阻值降低23.2%。关键词:复合集流体;卷绕镀膜;磁控溅射;镀铜;方块电阻中图分类号:TB43文献标识码:A文章编号:1002-0322(2023)04-0008-05doi:10.13385/j.cnki.vacuum.2023.04.02StudyoftheInfluenceofProcessParametersofCopperCoatingFabricatedbyRolltoRollMachineonElectronicPropertyofCompositeCurrentCollectorZHANGYan-peng,CAOZhi-qiang,FUQiang,CAOLei,LIUXu(BeijingNAURAVacuumTechnologyCo.,Ltd.,Beijing100015,China)Abstract:Bycontrollingwindingspeed,cathodepower,processpressure,linearionsourcecurrent,thicknessofNiCrseedlayer,rolltorollmagnetronsputteringmachinewasusedtodepositnano-copperfilmonthesurfaceoforganicfilmsubstrate,inordertoimproveelectronicpropertyofcoppercurrentcollector.Thesheetresistanceofcoppercoatingwascharacterizedbyfour-probemethod,andtheinfluenceofdifferentprocessparametersonthesheetresistanceofcoppercoatingwereobtained.Theresultsshowthatwiththeincreaseofrunningspeedofsubstrate,thesheetresistanceincreasesquadratically,andwiththeincreaseofcathodepower,thesheetresistancedecreasesinpower.Intheprocesspressurerangeof0.13~0.45Pa,thesheetresistancereachestheminimumat0.2Pa.Withtheionsourcecurrentincreasingintherangeof0~0.7A,thesheetresistancedecreaseslinearly.NiCrseedlayercanimprovethesheetresistanceofcopperlayer,andthesheetresistanceofcoppercoatingwith6.7nmNiCrseedlayeris23.2%lowerthanthatofcoppercoatin...