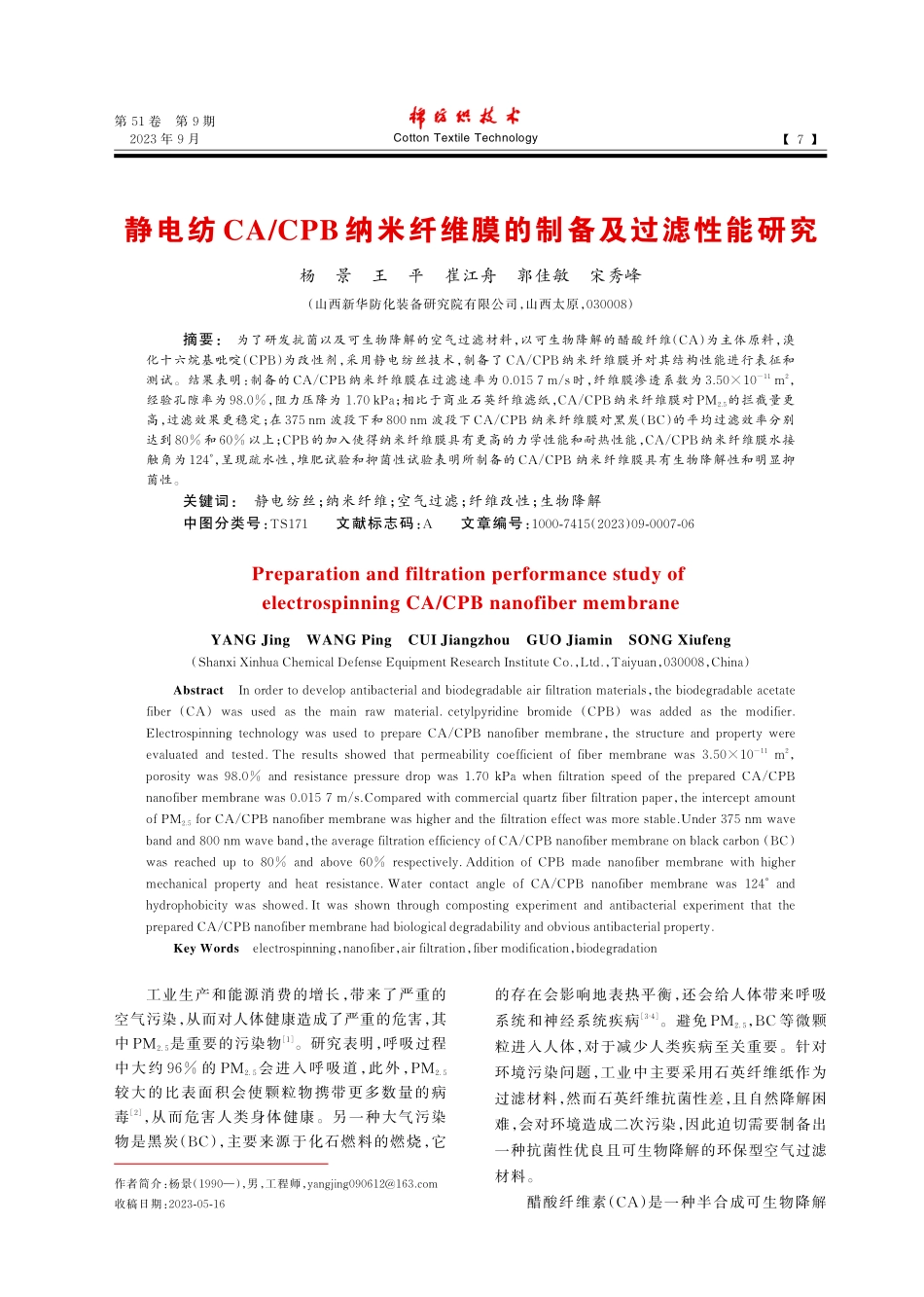

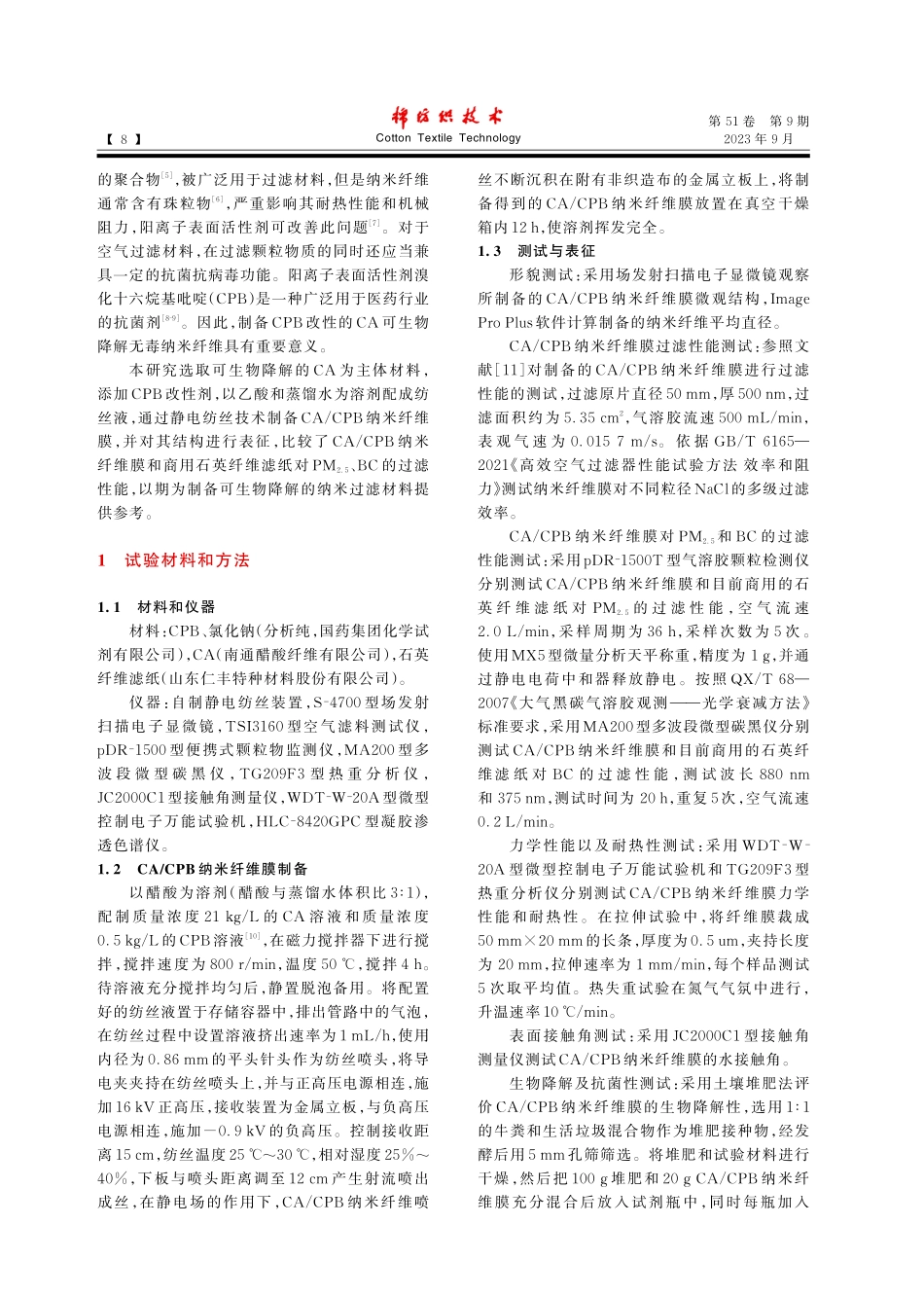

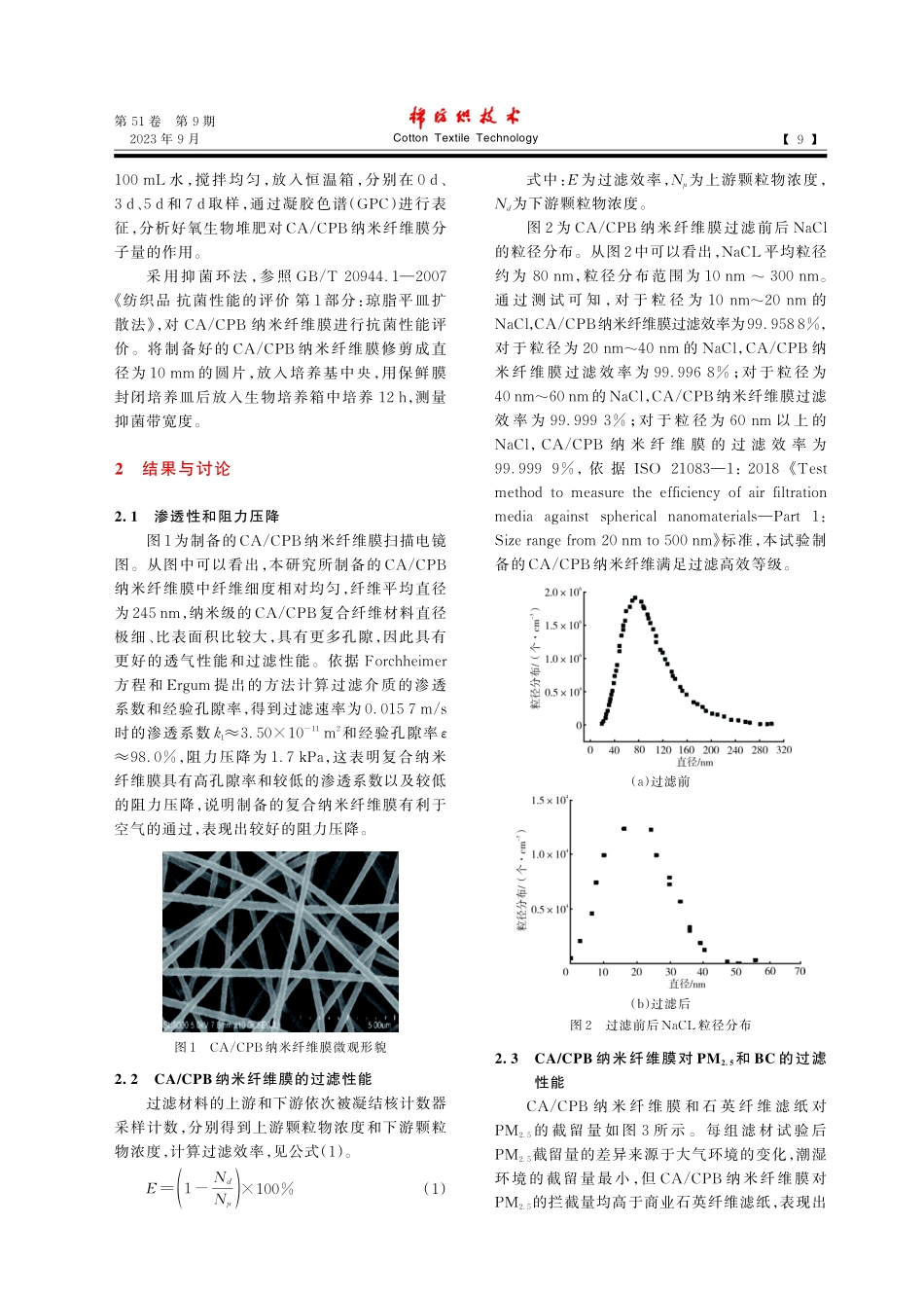

第51卷第9期2023年9月CottonTextileTechnology静电纺CA/CPB纳米纤维膜的制备及过滤性能研究杨景王平崔江舟郭佳敏宋秀峰(山西新华防化装备研究院有限公司,山西太原,030008)摘要:为了研发抗菌以及可生物降解的空气过滤材料,以可生物降解的醋酸纤维(CA)为主体原料,溴化十六烷基吡啶(CPB)为改性剂,采用静电纺丝技术,制备了CA/CPB纳米纤维膜并对其结构性能进行表征和测试。结果表明:制备的CA/CPB纳米纤维膜在过滤速率为0.0157m/s时,纤维膜渗透系数为3.50×10-11m2,经验孔隙率为98.0%,阻力压降为1.70kPa;相比于商业石英纤维滤纸,CA/CPB纳米纤维膜对PM2.5的拦截量更高,过滤效果更稳定;在375nm波段下和800nm波段下CA/CPB纳米纤维膜对黑炭(BC)的平均过滤效率分别达到80%和60%以上;CPB的加入使得纳米纤维膜具有更高的力学性能和耐热性能,CA/CPB纳米纤维膜水接触角为124°,呈现疏水性,堆肥试验和抑菌性试验表明所制备的CA/CPB纳米纤维膜具有生物降解性和明显抑菌性。关键词:静电纺丝;纳米纤维;空气过滤;纤维改性;生物降解中图分类号:TS171文献标志码:A文章编号:1000-7415(2023)09-0007-06PreparationandfiltrationperformancestudyofelectrospinningCA/CPBnanofibermembraneYANGJingWANGPingCUIJiangzhouGUOJiaminSONGXiufeng(ShanxiXinhuaChemicalDefenseEquipmentResearchInstituteCo.,Ltd.,Taiyuan,030008,China)AbstractInordertodevelopantibacterialandbiodegradableairfiltrationmaterials,thebiodegradableacetatefiber(CA)wasusedasthemainrawmaterial.cetylpyridinebromide(CPB)wasaddedasthemodifier.ElectrospinningtechnologywasusedtoprepareCA/CPBnanofibermembrane,thestructureandpropertywereevaluatedandtested.Theresultsshowedthatpermeabilitycoefficientoffibermembranewas3.50×10-11m2,porositywas98.0%andresistancepressuredropwas1.70kPawhenfiltrationspeedofthepreparedCA/CPBnanofibermembranewas0.0157m/s.Comparedwithcommercialquartzfiberfiltrationpaper,theinterceptamountofPM2.5forCA/CPBnanofibermembranewashigherandthefiltrationeffectwasmorestable.Under375nmwavebandand800nmwaveband,theaveragefiltrationefficiencyofCA/CPBnanofibermembraneonblackcarbon(BC)wasreachedupto80%andabove60%respectively.AdditionofCPBmadenanofibermembranewithhighe...