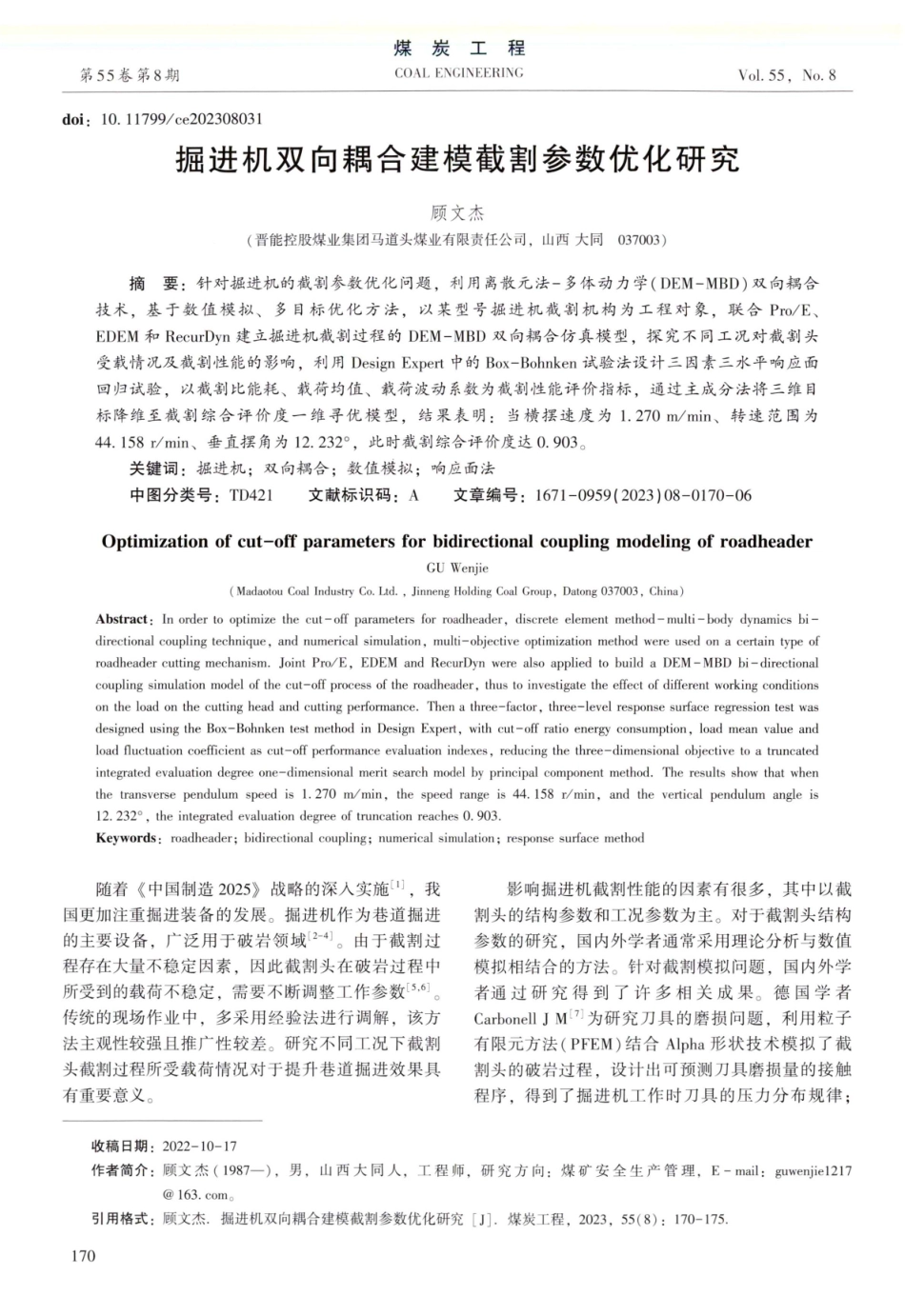

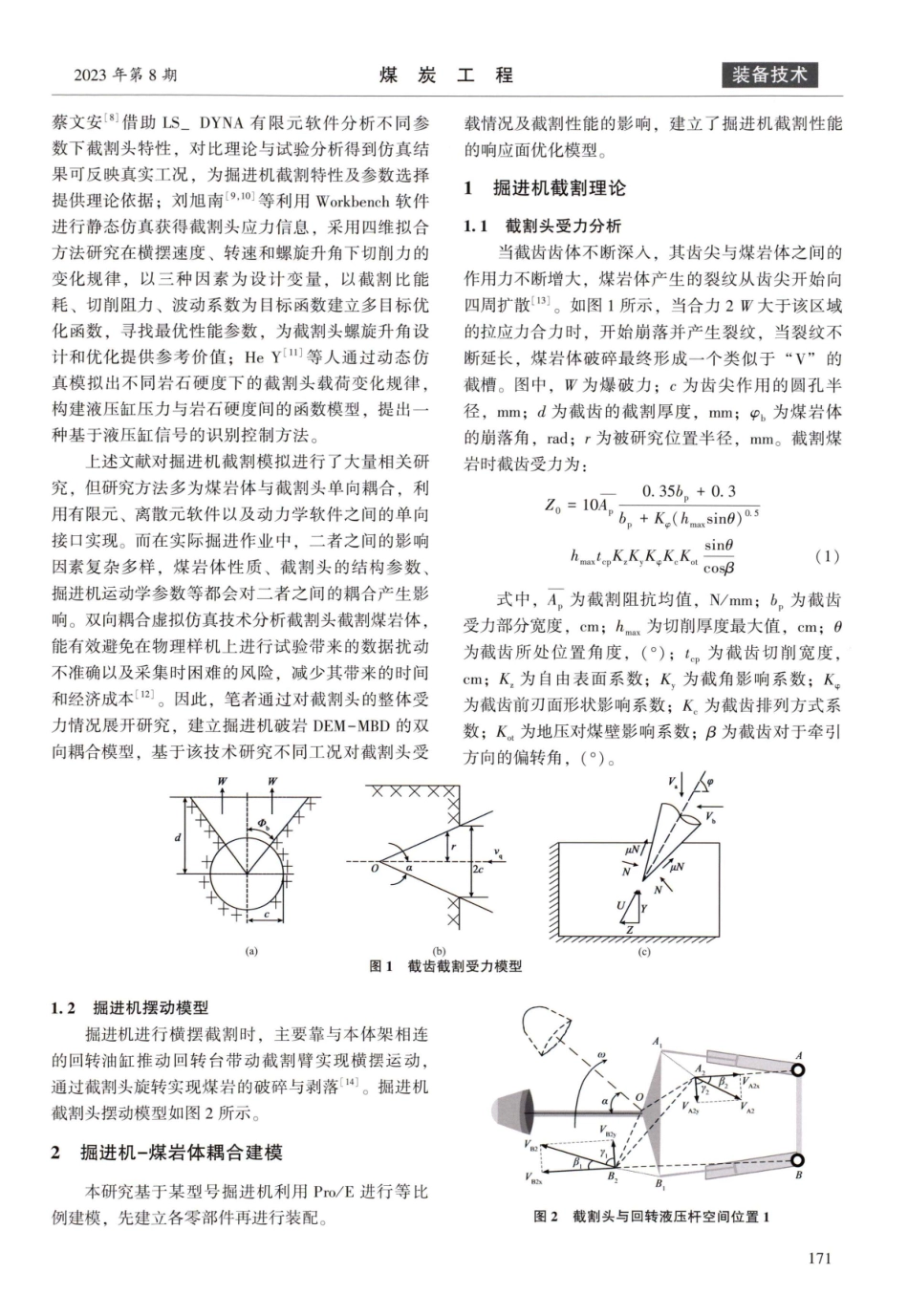

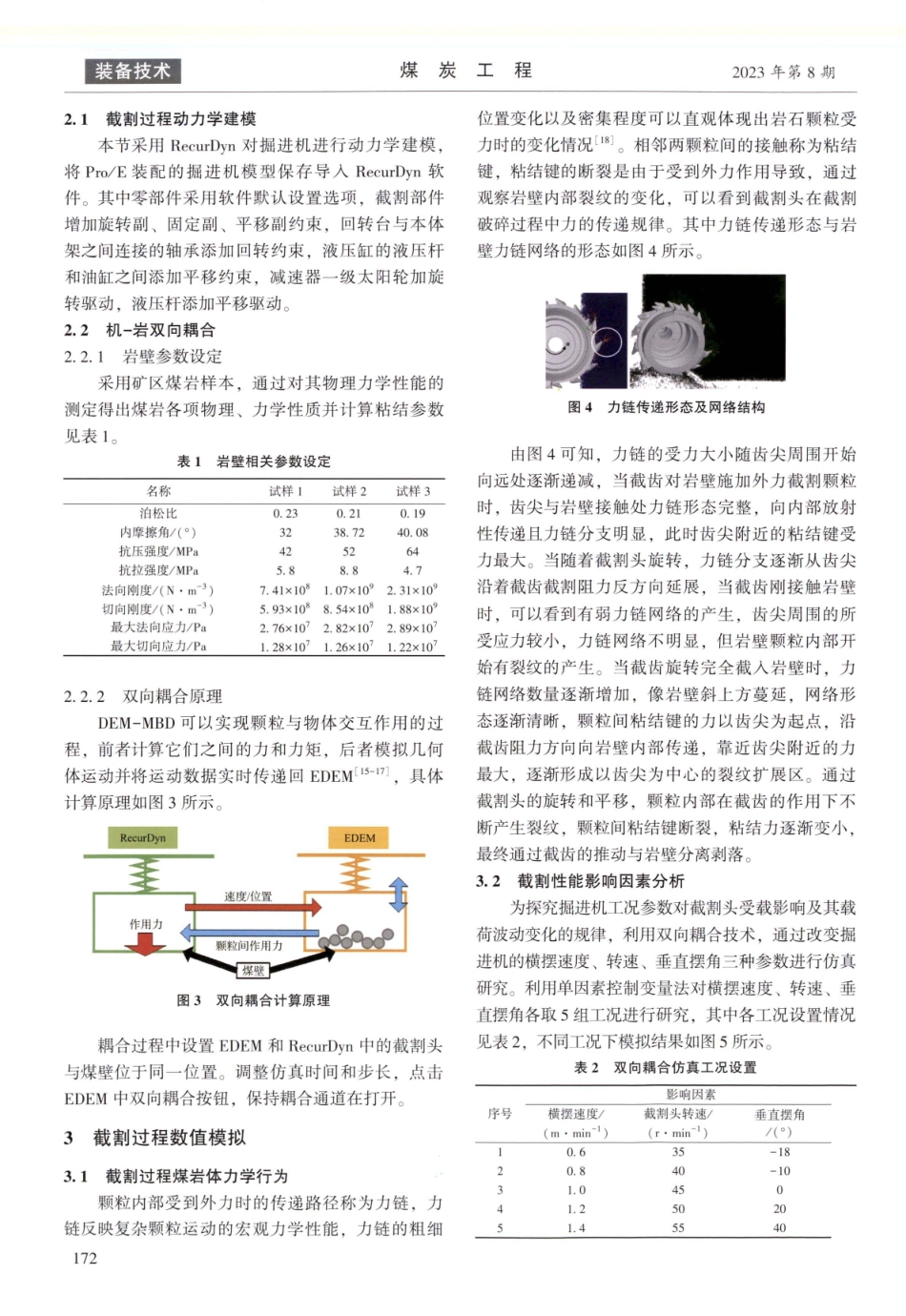

170引用格式:顾文杰.掘进机双向耦合建模截割参数优化研究[J]:煤炭工程,2023,55(8):170-175.Vol.55.No.8第55卷第8期COALENGINEERING程炭煤doi:10.11799/ce202308031掘进机双向耦合建模截割参数优化研究顾文杰(晋能控股煤业集团马道头煤业有限责任公司,山西大同037003)摘要:针对掘进机的截割参数优化问题,利用离散元法-多体动力学(DEM-MBD)双向耦合技术,基于数值模拟、多目标优化方法,以某型号掘进机截割机构为工程对象,联合Pro/E、EDEM和RecurDyn建立掘进机截割过程的DEM-MBD双向耦合仿真模型,探究不同工况对截割头受载情况及截割性能的影响,利用DesignExpert中的Box-Bohnken试验法设计三因素三水平响应面回归试验,以截割比能耗、载荷均值、载荷波动系数为截割性能评价指标,通过主成分法将三维目标降维至截割综合评价度一维寻优模型,结果表明:当横摆速度为1.270m/min、转速范围为44.158r/min、垂直摆角为12.232°,此时截割综合评价度达0.903。关键词:掘进机;双向耦合;数值模拟;响应面法中图分类号:TD421文献标识码:A文章编号:1671-0959(2023)08-0170-06Optimizationofcut-offparametersforbidirectionalcouplingmodelingofroadheadeGUWenjie(MadaotouCoalIndustryCo.Ltd.,JinnengHoldingCoalGroup,Datong037003,China)Abstract:Inordertooptimizethecut-offparametersforroadheader,discreteelementmethod-multi-bodydynamicsbi-directionalcouplingtechnique,andnumericalsimulation,multi-objectiveoptimizationmethodwereusedonacertaintypeofroadheadercuttingmechanism.JointPro/E,EDEMandRecurDynwerealsoappliedtobuildaDEM-MBDbi-directionalcouplingsimulationmodelofthecut-offprocessoftheroadheader,thustoinvestigatetheeffectofdifferentworkingconditionsontheloadonthecuttingheadandcuttingperformance.Thenathree-factor,three-levelresponsesurfaceregressiontestwasdesignedusingtheBox-BohnkentestmethodinDesignExpert,withcut-offratioenergyconsumption,loadmeanvalueandloadfluctuationcoefficientascut-offperformanceevaluationindexes,reducingthethree-dimensionalobjectivetoatruncatedintegratedevaluationdegreeone-dimensionalmeritsearchmodelbyprincipalcomponentmethod.Theresultsshowthatwhenthetransversependulumspeedis1.270m/min,thespeedrangeis44.158r/min,andthevertic...