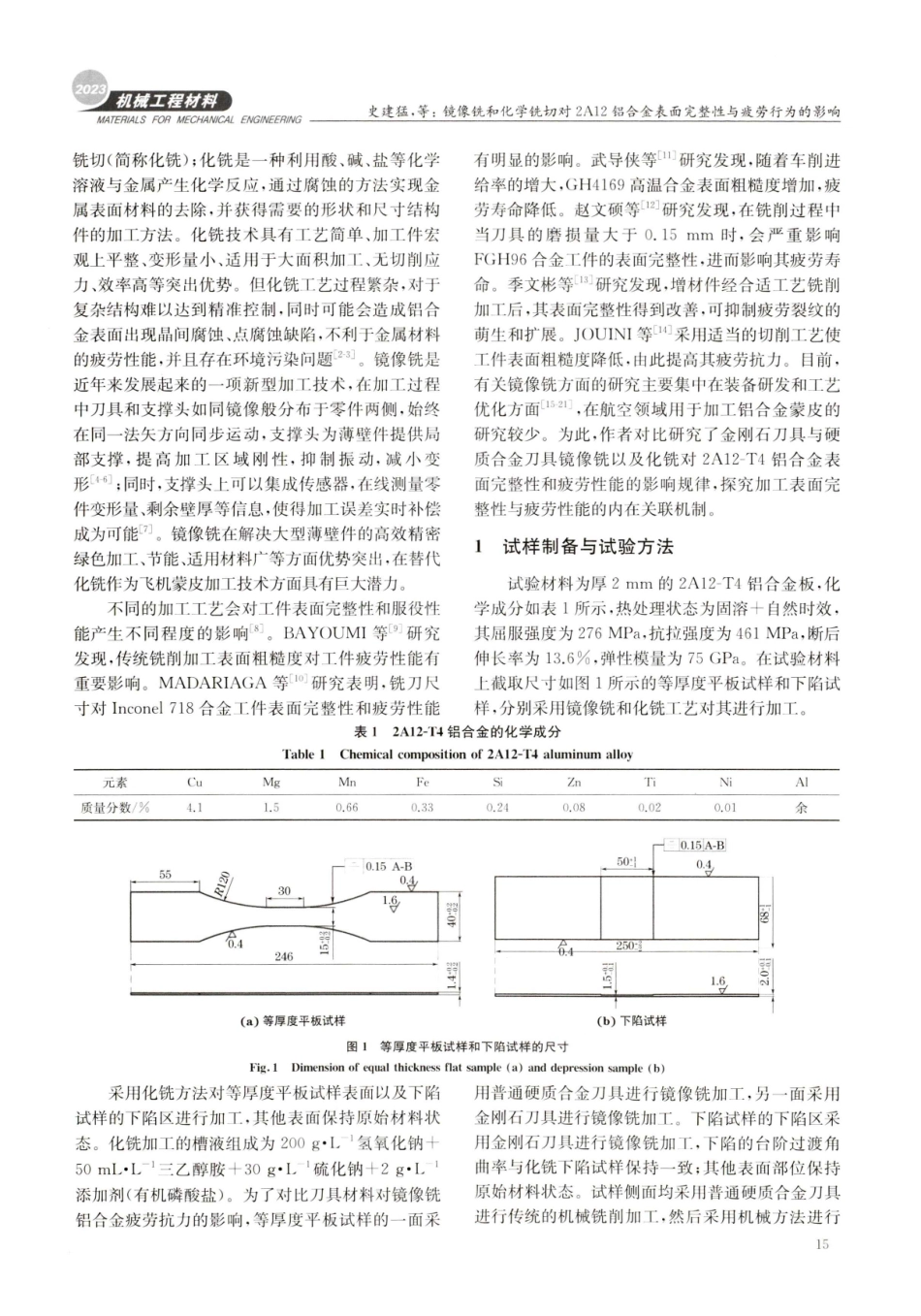

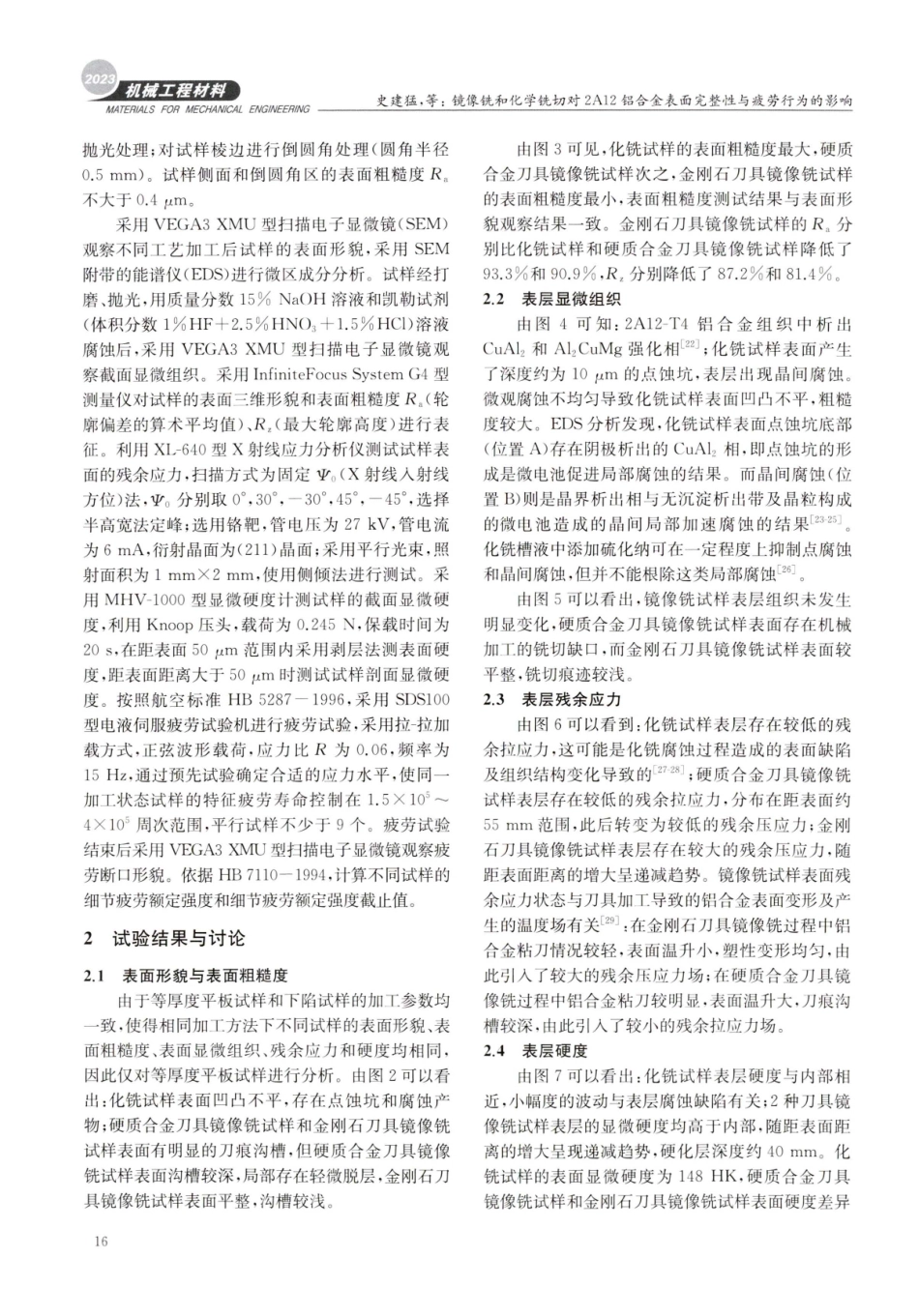

14DOI:10.11973xgccl202307003MATERIALSFORMECHANICALENGINEERINGVol.47No.7Jul.20232023年7月第47卷第7期机械工程材料镜像铣和化学铣切对2A12铝合金表面完整性与疲劳行为的影响史建猛",张海宝",张月玲",贾天一²,王新磊",陈奕志”,刘道新²(1.中航西安飞机工业集团股份有限公司,西安710089;2.西北工业大学民航学院,西安710072)摘要:对比研究了金刚石刀具和硬质合金刀具镜像铣,以及化学铣切2A12-T4铝合金试样的表面形貌、表面粗糙度、残余应力、硬度和疲劳性能。结果表明:镜像铣等厚度平板试样(一面硬质合金刀具加工,一面金刚石刀具加工)的细节疲劳额定强度比化学铣切试样提高了4.27%,而金刚石刀具镜像铣下陷试样的细节疲劳额定强度则提高了22.46%;金刚石刀具镜像铣试样获得了比硬质合金刀具镜像铣试样以及化学铣切试样更高的疲劳抗力。金刚石刀具镜像铣在试样表面引入了残余压应力,提高了表面硬度,降低了表面粗糙度,并未使表层组织受到破坏,因此裂纹萌生和扩展阻力提高。化学铣切试样表面存在的点蚀坑、晶间腐蚀缺陷及残余拉应力,以及硬质合金刀具镜像铣试样表面存在的较深刀痕沟槽和残余拉应力均促进了裂纹的萌生。关键词:镜像铣切;化学铣切;2A12-T4铝合金;疲劳性能;表面完整性中图分类号:TG714文献标志码:A文章编号:1000-3738(2023)07-0014-08EffectofMirrorMillingandChemicalMillingonSurfaceIntegrityandFatigueBehaviorof2A12AluminumAlloySHIJianmeng',ZHANGHaibao',ZHANGYueling',JIATianyi?,WANGXinlei',CHENYizhi?,LIUDaoxin?(1.AVICXi'anAircraftIndustryGroupCompanyLtd.,Xi'an710089,China;2.CollegeofCivilAviation,NorthwesternPolytechnicalUniversity,Xi'an710072,China)Abstract:Thesurfacemorphology,surfaceroughness,residualstress,hardnessandfatiguepropertiesof2A12-T4aluminumalloysamplesprocessedbydiamondtoolandcarbidetoolmirrormillingandchemicalmillingwerestudiedbycontrast.Theresultsshowthatcomparingwiththatofchemicalmilledsamples,thedetailedfatigueratedstrengthofcarbidetoolmirrormilledequalthicknessflatsample(onesideforcarbidetoolprocessingandtheothersidefordiamondtoolprocessing)wasimprovedby4.27%,whilethatofdiamondtoolmirrormilleddepressionsamplewasimprovedby22.46%.Thefatigueresistanceofdiamondtoolmirrormilledsamplewashigherthanthatofcar...