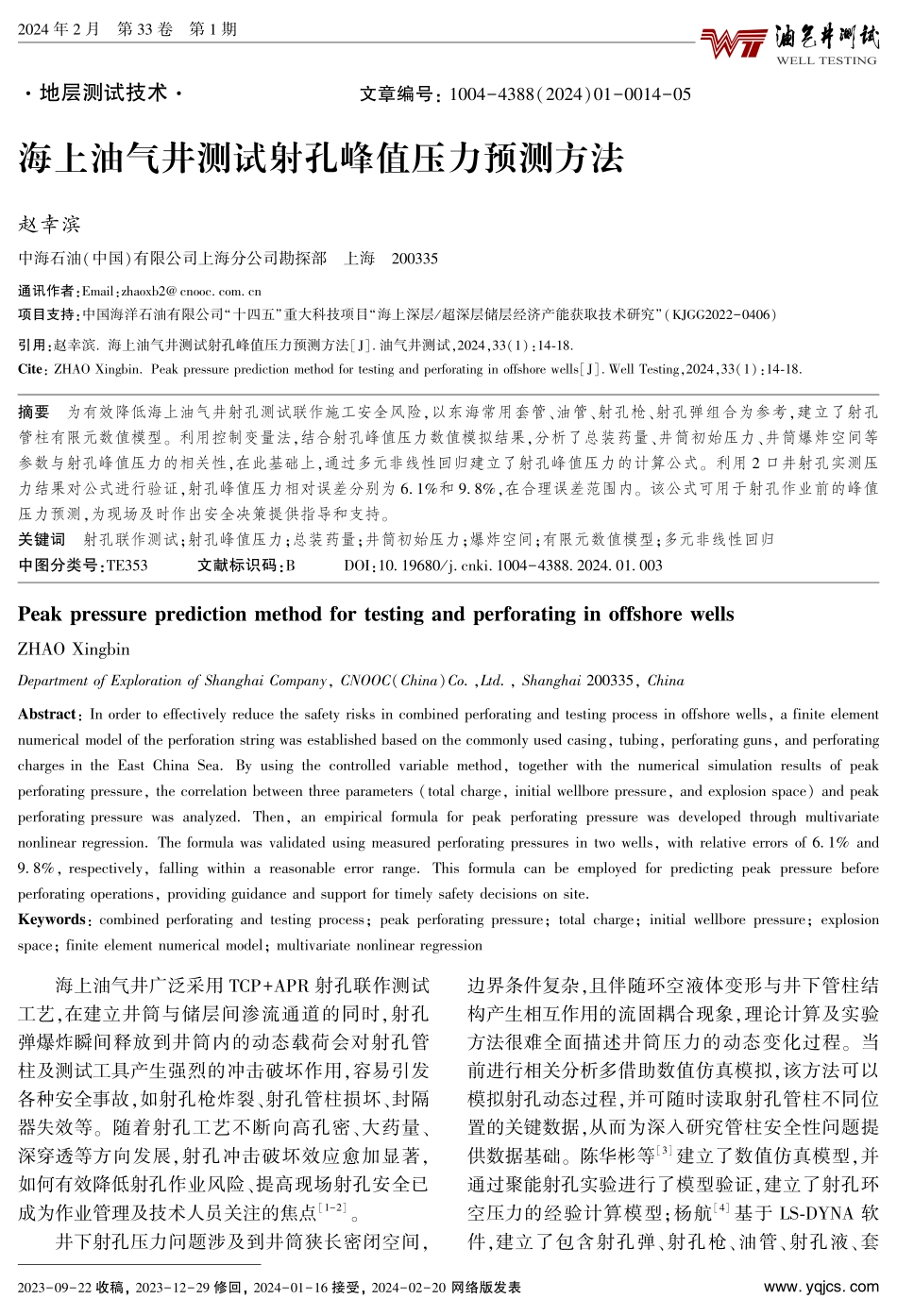

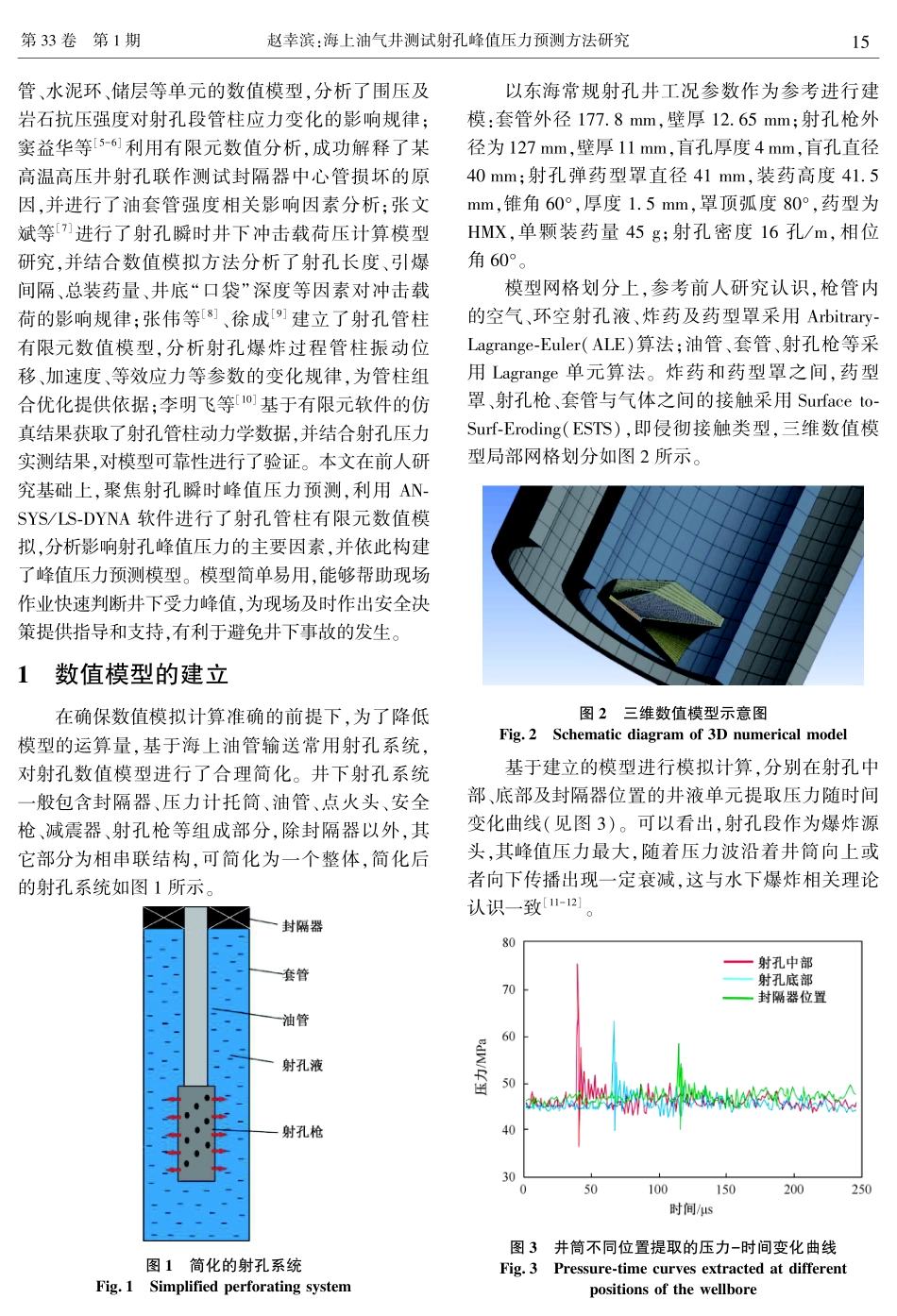

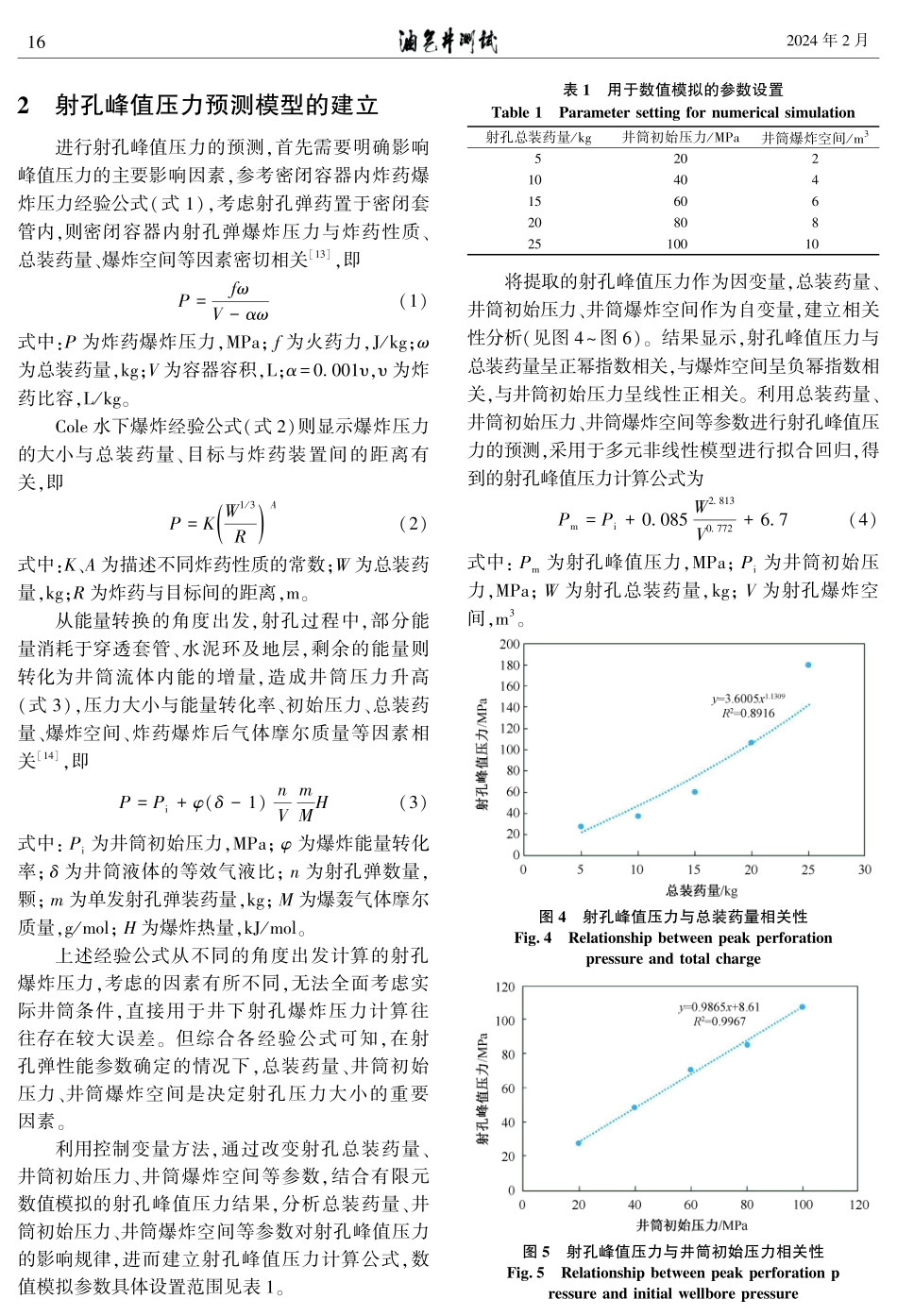

2024年2月第33卷第1期·地层测试技术·文章编号:1004-4388(2024)01-0014-052023-09-22收稿,2023-12-29修回,2024-01-16接受,2024-02-20网络版发表www.yqjcs.com海上油气井测试射孔峰值压力预测方法赵幸滨中海石油(中国)有限公司上海分公司勘探部上海200335通讯作者:Email:zhaoxb2@cnooc.com.cn项目支持:中国海洋石油有限公司“十四五”重大科技项目“海上深层/超深层储层经济产能获取技术研究”(KJGG2022-0406)引用:赵幸滨.海上油气井测试射孔峰值压力预测方法[J].油气井测试,2024,33(1):14-18.Cite:ZHAOXingbin.Peakpressurepredictionmethodfortestingandperforatinginoffshorewells[J].WellTesting,2024,33(1):14-18.摘要为有效降低海上油气井射孔测试联作施工安全风险,以东海常用套管、油管、射孔枪、射孔弹组合为参考,建立了射孔管柱有限元数值模型。利用控制变量法,结合射孔峰值压力数值模拟结果,分析了总装药量、井筒初始压力、井筒爆炸空间等参数与射孔峰值压力的相关性,在此基础上,通过多元非线性回归建立了射孔峰值压力的计算公式。利用2口井射孔实测压力结果对公式进行验证,射孔峰值压力相对误差分别为6.1%和9.8%,在合理误差范围内。该公式可用于射孔作业前的峰值压力预测,为现场及时作出安全决策提供指导和支持。关键词射孔联作测试;射孔峰值压力;总装药量;井筒初始压力;爆炸空间;有限元数值模型;多元非线性回归中图分类号:TE353文献标识码:BDOI:10.19680/j.cnki.1004-4388.2024.01.003PeakpressurepredictionmethodfortestingandperforatinginoffshorewellsZHAOXingbinDepartmentofExplorationofShanghaiCompany,CNOOC(China)Co.,Ltd.,Shanghai200335,ChinaAbstract:Inordertoeffectivelyreducethesafetyrisksincombinedperforatingandtestingprocessinoffshorewells,afiniteelementnumericalmodeloftheperforationstringwasestablishedbasedonthecommonlyusedcasing,tubing,perforatingguns,andperforatingchargesintheEastChinaSea.Byusingthecontrolledvariablemethod,togetherwiththenumericalsimulationresultsofpeakperforatingpressure,thecorrelationbetweenthreeparameters(totalcharge,initialwellborepressure,andexplosionspace)andpeakperforatingpressurewasanalyzed.Then,anempiricalformulaforpeakperforatingpressurewasdevelopedthroughmultivariatenonlinearregression.Theformulawasvalidatedusingmeasuredperfora...