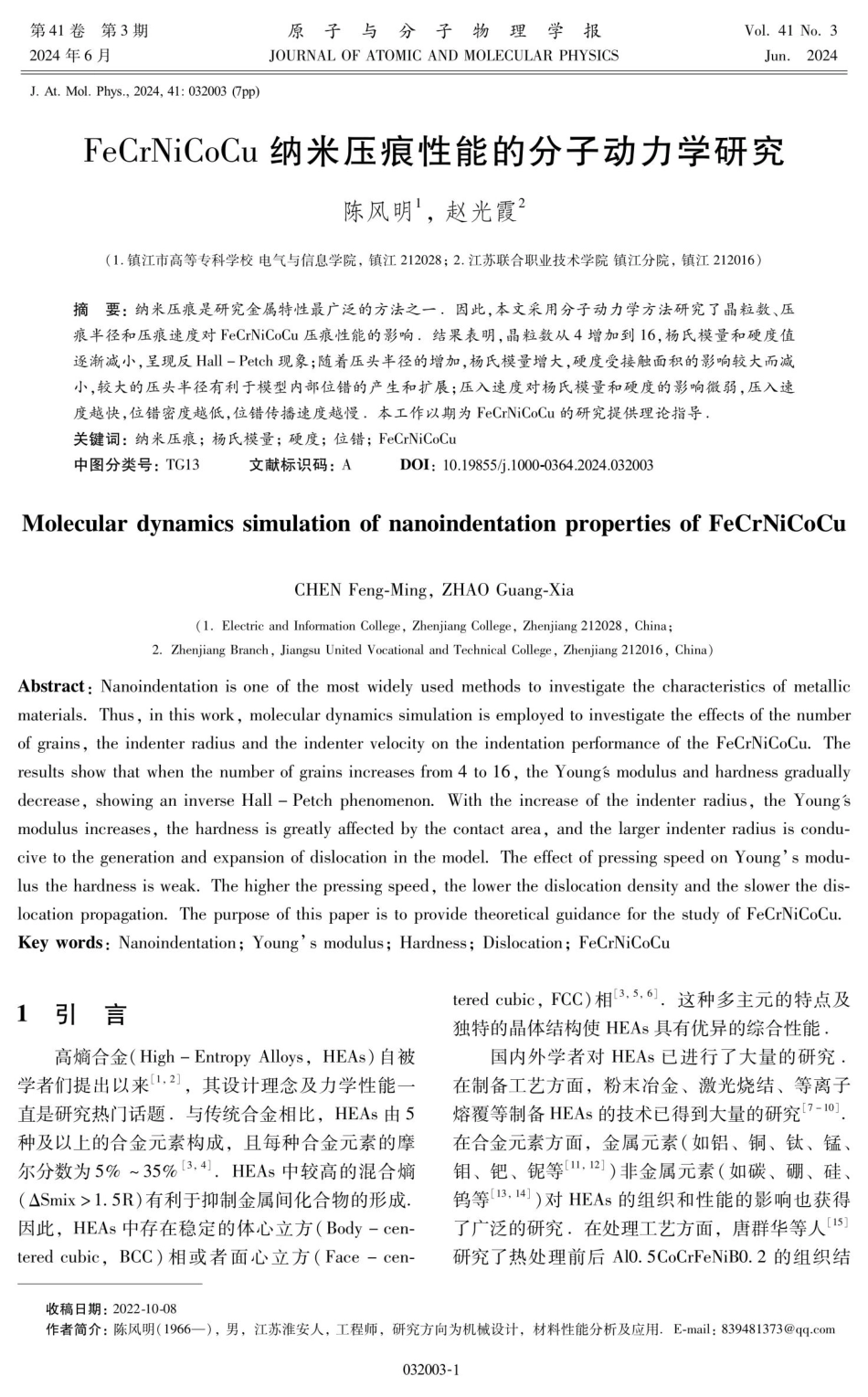

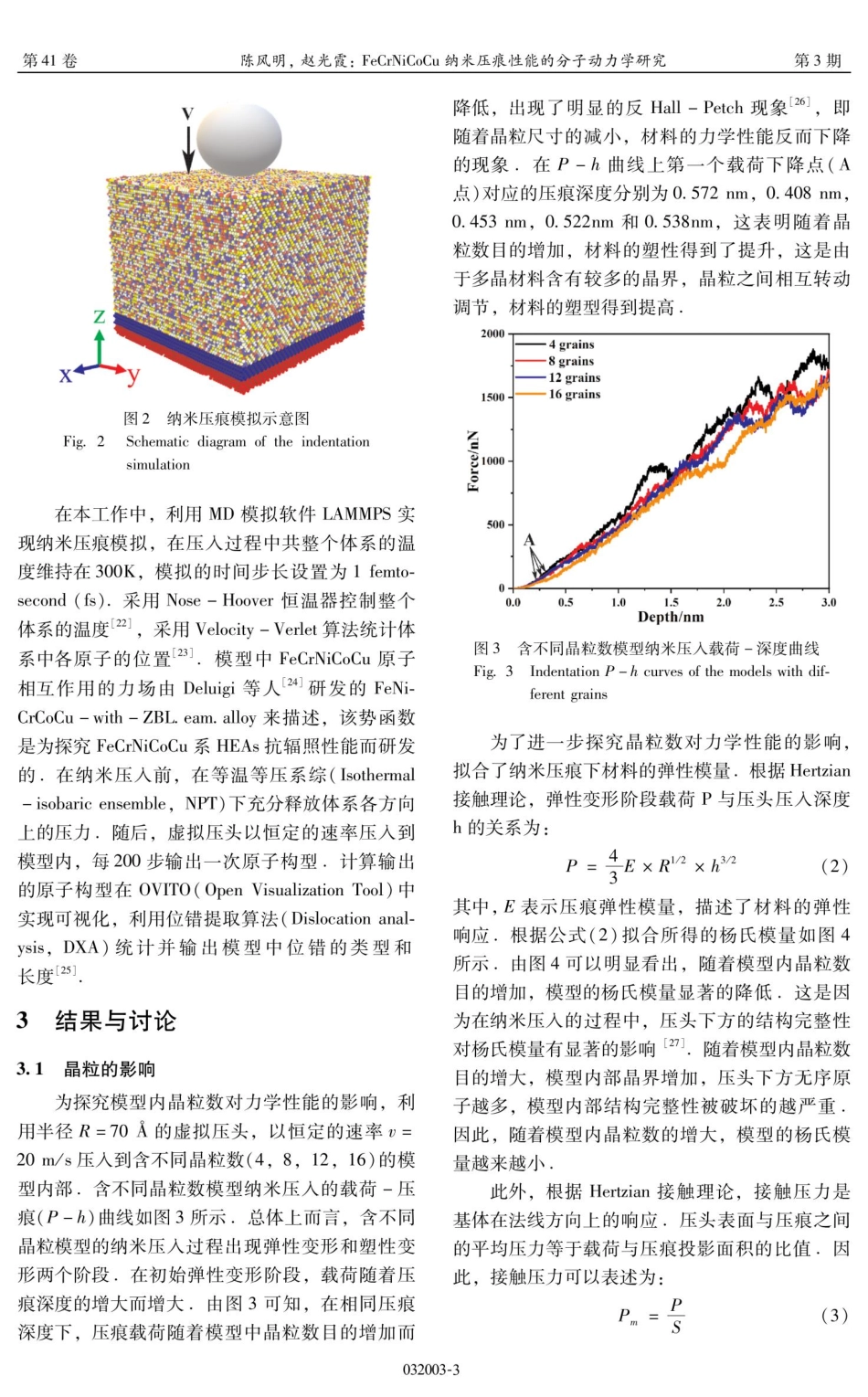

第41卷第3期2024年6月J.At.Mol.Phys.,2024,41:032003(7pp)FeCrNiCoCu纳米压痕性能的分子动力学研究原子与分子物理学报JOURNALOFATOMICANDMOLECULARPHYSICSVol.41No.3Jun.2024陈风明,赵光霞(1.镇江市高等专科学校电气与信息学院,镇江212028;2.江苏联合职业技术学院镇江分院,镇江212016)摘要:纳米压痕是研究金属特性最广泛的方法之一,因此,本文采用分子动力学方法研究了晶粒数、压痕半径和压痕速度对FeCrNiCoCu压痕性能的影响:结果表明,晶粒数从4增加到16,杨氏模量和硬度值逐渐减小,呈现反Hall-Petch现象;随着压头半径的增加,杨氏模量增大,硬度受接触面积的影响较大而减小,较大的压头半径有利于模型内部位错的产生和扩展;压入速度对杨氏模量和硬度的影响微弱,压入速度越快,位错密度越低,位错传播速度越慢,本工作以期为FeCrNiCoCu的研究提供理论指导.关键词:纳米压痕;杨氏模量;硬度;位错;FeCrNiCoCu中图分类号:TG13MoleculardynamicssimulationofnanoindentationpropertiesofFeCrNiCoCu文献标识码:AD0I:10.19855/j.1000-0364.2024.032003CHENFeng-Ming,ZHAOGuang-Xia(1.ElectricandInformationCollege,ZhenjiangCollege,Zhenjiang212028,China;2.ZhenjiangBranch,JiangsuUnitedVocationalandTechnicalCollege,Zhenjiang212016,China)Abstract:Nanoindentationisoneofthemostwidelyusedmethodstoinvestigatethecharacteristicsofmetallicmaterials.Thus,inthiswork,moleculardynamicssimulationisemployedtoinvestigatetheeffectsofthenumberofgrains,theindenterradiusandtheindentervelocityontheindentationperformanceoftheFeCrNiCoCu.Theresultsshowthatwhenthenumberofgrainsincreasesfrom4to16,theYoungsmodulusandhardnessgraduallydecrease,showinganinverseHall-Petchphenomenon.Withtheincreaseoftheindenterradius,theYoung'smodulusincreases,thehardnessisgreatlyaffectedbythecontactarea,andthelargerindenterradiusiscondu-civetothegenerationandexpansionofdislocationinthemodel.TheeffectofpressingspeedonYoung'smodu-lusthehardnessisweak.Thehigherthepressingspeed,thelowerthedislocationdensityandtheslowerthedis-locationpropagation.ThepurposeofthispaperistoprovidetheoreticalguidanceforthestudyofFeCrNiCoCu.Keywords:Nanoindentation;Young'smodulus;Hardness;Dislocation;FeCrNiCoCu...