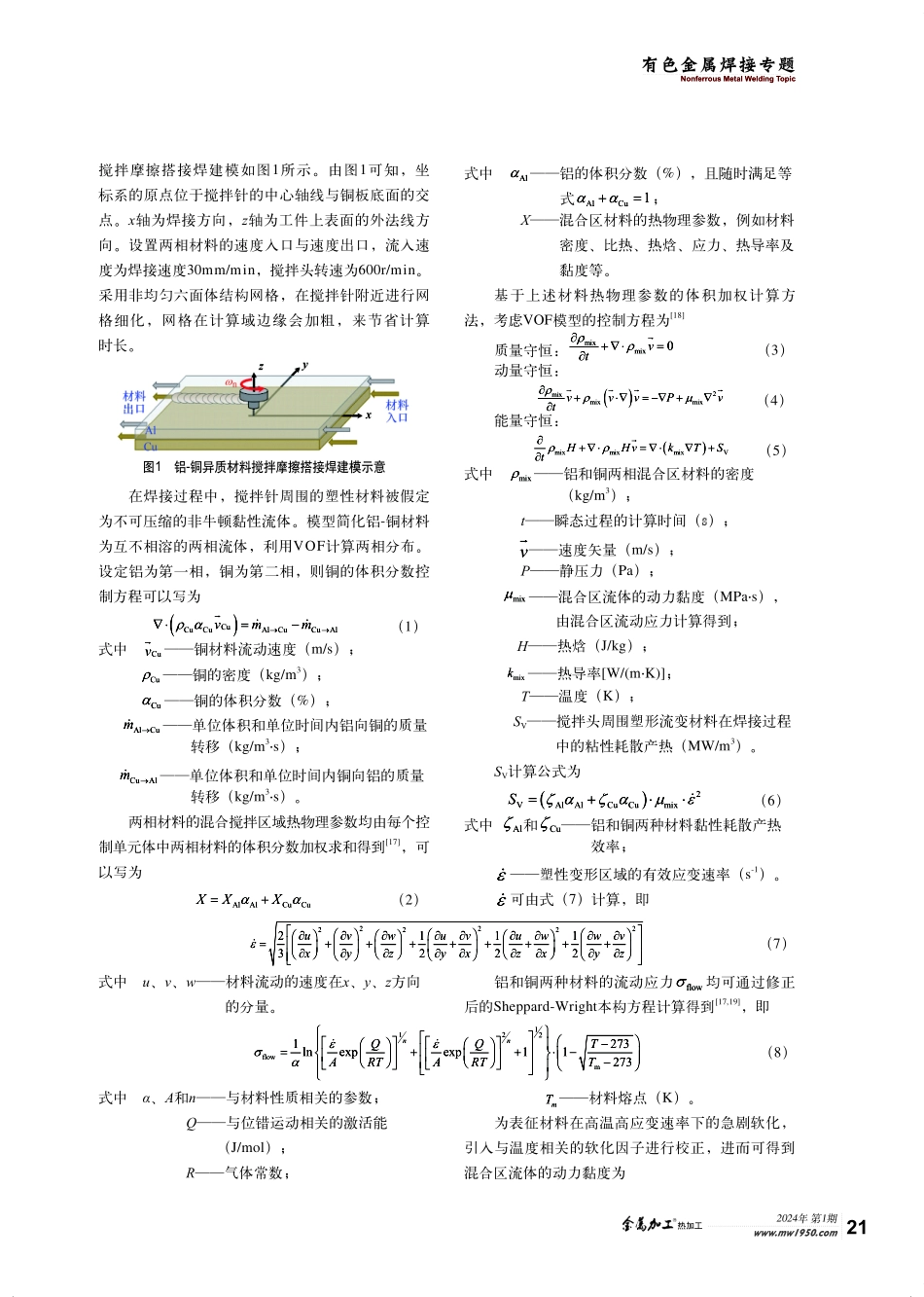

2024年第1期热加工www.mw1950.com19有色金属焊接专题NonferrousMetalWeldingTopic搅拌针长度对铝-铜搭接搅拌摩擦焊影响机制的数值模拟研究赵文祯1,朱亚龙1,付遨2,何欢11.烟台大学核装备与核工程学院山东烟台2640052.中南大学粉末冶金研究院湖南长沙410083摘要:利用流体动力学的计算方法,分别建立了长度为2.4mm和2.8mm搅拌针的铝-铜异质材料搅拌摩擦搭接焊模型。基于VOF计算铝-铜两相分布的方法,定量分析了不同长度的搅拌针下两相材料流动和界面热-力耦合效应。通过界面摩擦切应力与热流通过搅拌头与工件接触界面的相对滑移状态计算,搭建了随材料流动状态变化的界面动态自适应热力模型。分析发现:增加搅拌针长度能有效强化两相材料的混合与搅拌区的塑性变形,焊缝后退侧的钩状组织更加尖锐。随着材料流动速度提升,界面摩擦切应力降低,进而引起界面摩擦产热和热流密度降低。但局部塑性流动的增强提升了塑性变形区域的黏性耗散产热和温度,且铝在垂直方向上的迁移更加剧烈,使铝-铜异质金属搭接界面的混合区扩大。此外,通过将仿真得到的焊缝横断面两相材料的界面分布与相关文献试验数据进行对比,验证了模型的准确性。关键词:搅拌摩擦焊;铝-铜异质材料搭接;数值模拟;搅拌针长度;热力耦合NumericalsimulationontheinfluencemechanismofpinlengthonAl-CulapFSWZHAOWenzhen1,ZHUYalong1,FUAo2,HEHuan11.SchoolofNuclearEquipmentandNuclearEngineering,YantaiUniversity,Yantai264005,Shandong,China2.StateKeyLaboratoryofPowderMetallurgy,CentralSouthUniversity,Changsha410083,Hunan,ChinaAbstract:Inthispaper,themodelsofAl-Cuheterogeneousfrictionstirlapweldingwithpinlengthof2.4mmand2.8mmwereestablishedbythemethodofcomputationalfluiddynamics.BasedonVOFmethod,thetwo-phasedistributionofaluminumandcopperwascalculated,andthethermal-mechanicalcouplingeffectoftwo-phasematerialflowunderdifferentpinswasquantitativelyanalyzed.Theinterfacialfrictionshearstressandheatflowwerecalculatedbytherelativeslidingstateofthetool/workpiececontactinterface.Itwasfoundthattheincreaseofpinlengthcouldeffectivelyenhancethemixingoftwo-phasematerials,strengthentheplasticdeformation,andenlargethehookstructure.Withtheincreaseofmaterialflow,theinterfacialfrictionshearstressdecreases,whichledtothedecr...