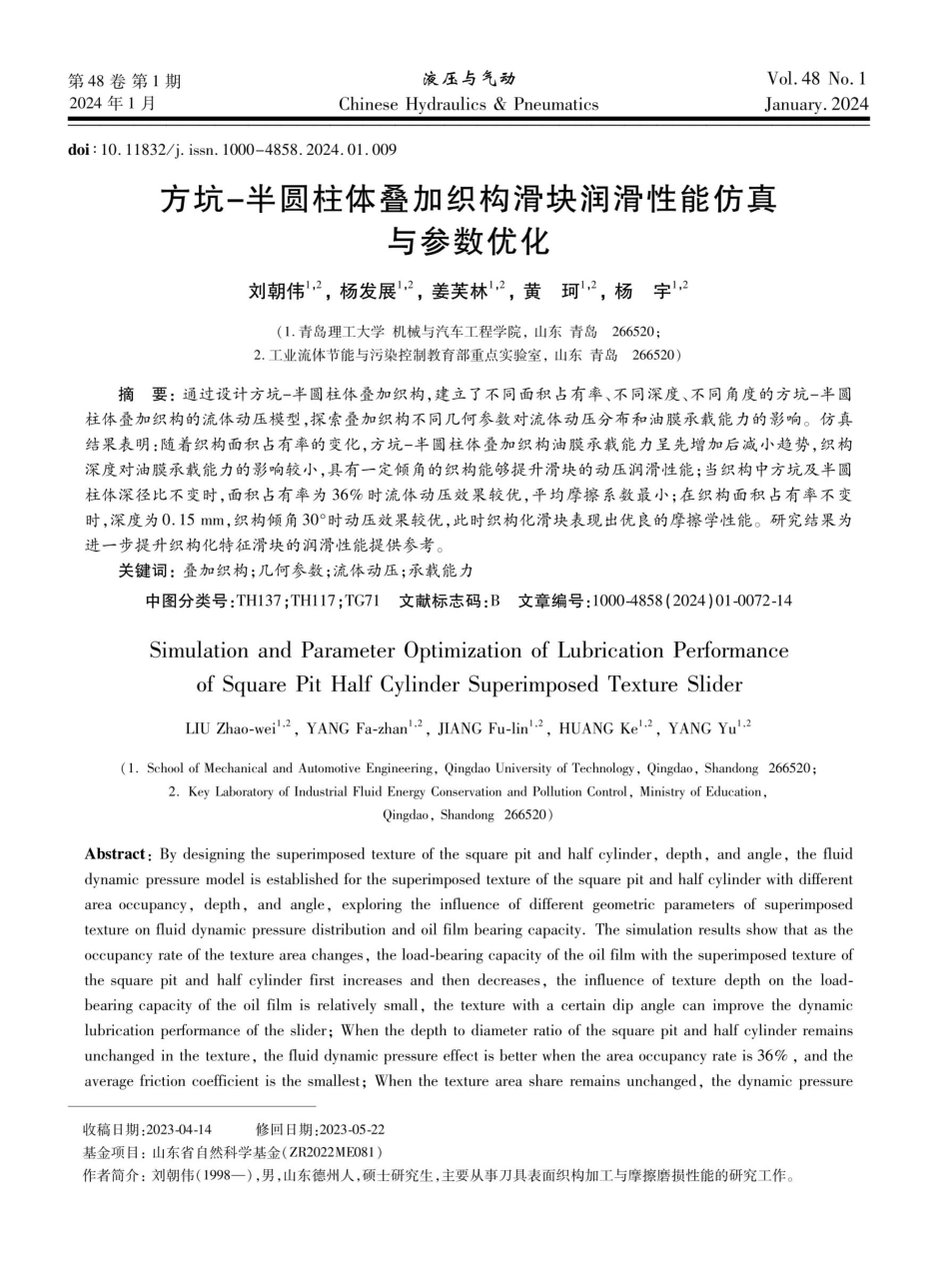

第48卷第1期2024年1月doi:10.11832/j.issn.1000-4858.2024.01.009方坑-半圆柱体叠加织构滑块润滑性能仿真与参数优化刘朝伟²,杨发展"²,姜芙林2,黄珂²,杨宇12(1.青岛理工大学机械与汽车工程学院,山东青岛266520;2.工业流体节能与污染控制教育部重点实验室,山东青岛266520)摘要:通过设计方坑-半圆柱体叠加织构,建立了不同面积占有率、不同深度、不同角度的方坑-半圆柱体叠加织构的流体动压模型,探索叠加织构不同几何参数对流体动压分布和油膜承载能力的影响。仿真结果表明:随着织构面积占有率的变化,方坑-半圆柱体叠加织构油膜承载能力呈先增加后减小趋势,织构深度对油膜承载能力的影响较小,具有一定倾角的织构能够提升滑块的动压润滑性能;当织构中方坑及半圆柱体深径比不变时,面积占有率为36%时流体动压效果较优,平均摩擦系数最小;在织构面积占有率不变时,深度为0.15mm,织构倾角30°时动压效果较优,此时织构化滑块表现出优良的摩擦学性能。研究结果为进一步提升织构化特征滑块的润滑性能提供参考。关键词:叠加织构;几何参数;流体动压;承载能力中图分类号:TH137;TH117;TG71文献标志码:BSimulationandParameterOptimizationofLubricationPerformanceofSquarePitHalfCylinderSuperimposedTextureSliderLIUZhao-wei'-2,YANGFa-zhan'-2,JIANGFu-lin'*2,HUANGKe'2,YANGYul.(1.SchoolofMechanicalandAutomotiveEngineering,QingdaoUniversityofTechnology,Qingdao,Shandong266520;2.KeyLaboratoryofIndustrialFluidEnergyConservationandPollutionControl,MinistryofEducation,Abstract:Bydesigningthesuperimposedtextureofthesquarepitandhalfcylinder,depth,andangle,thefluiddynamicpressuremodelisestablishedforthesuperimposedtextureofthesquarepitandhalfcylinderwithdifferentareaoccupancy,depth,andangle,exploringtheinfluenceofdifferentgeometricparametersofsuperimposedtextureonfluiddynamicpressuredistributionandoilfilmbearingcapacity.Thesimulationresultsshowthatastheoccupancyrateofthetextureareachanges,theload-bearingcapacityoftheoilfilmwiththesuperimposedtextureofthesquarepitandhalfcylinderfirstincreasesandthendecreases,theinfluenceoftexturedepthontheload-bearingcapacityoftheoilfilmisrelativelysmall,thetexturewithacertaindipanglecanimprovethedynamiclubricationperfo...