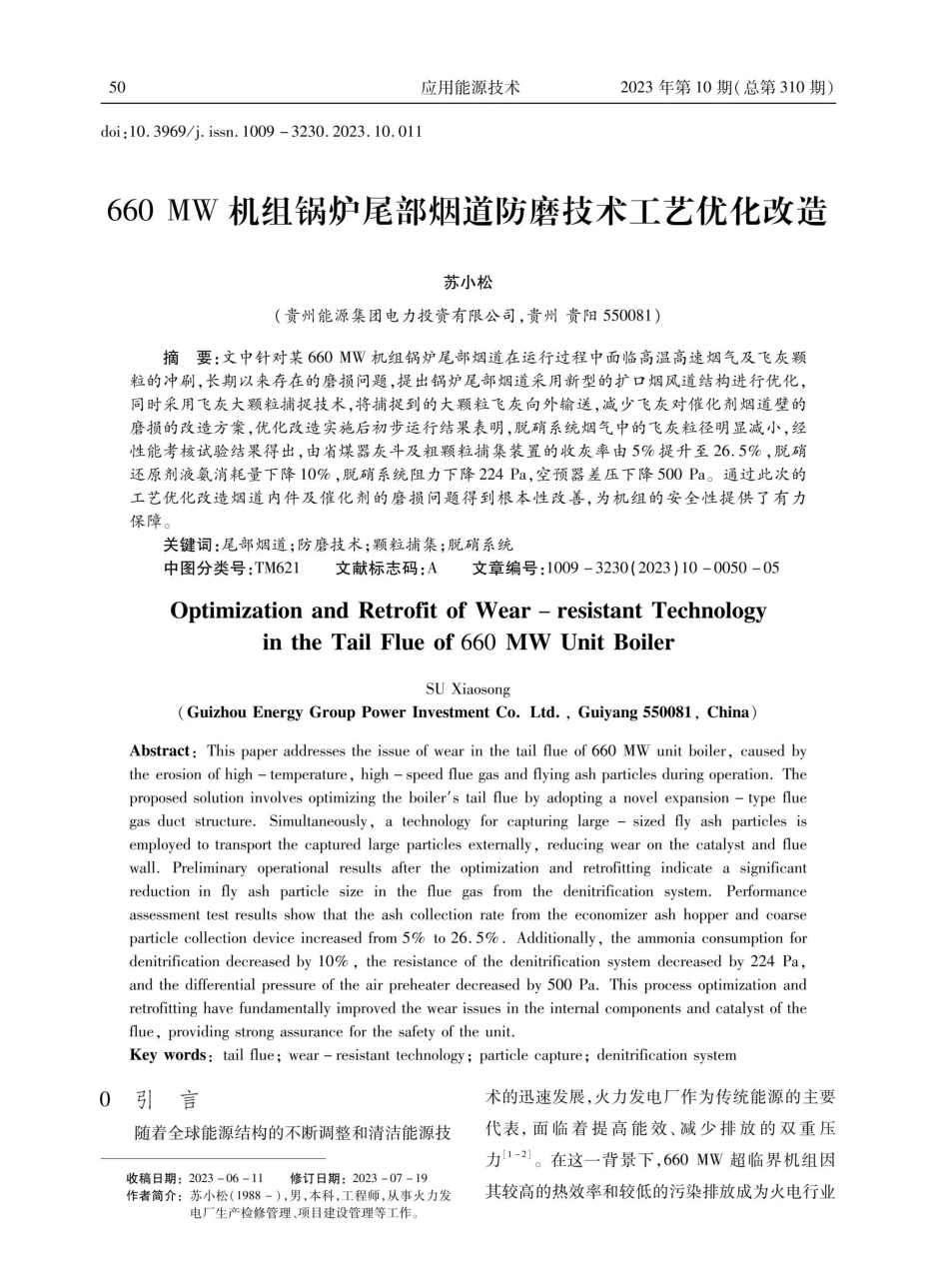

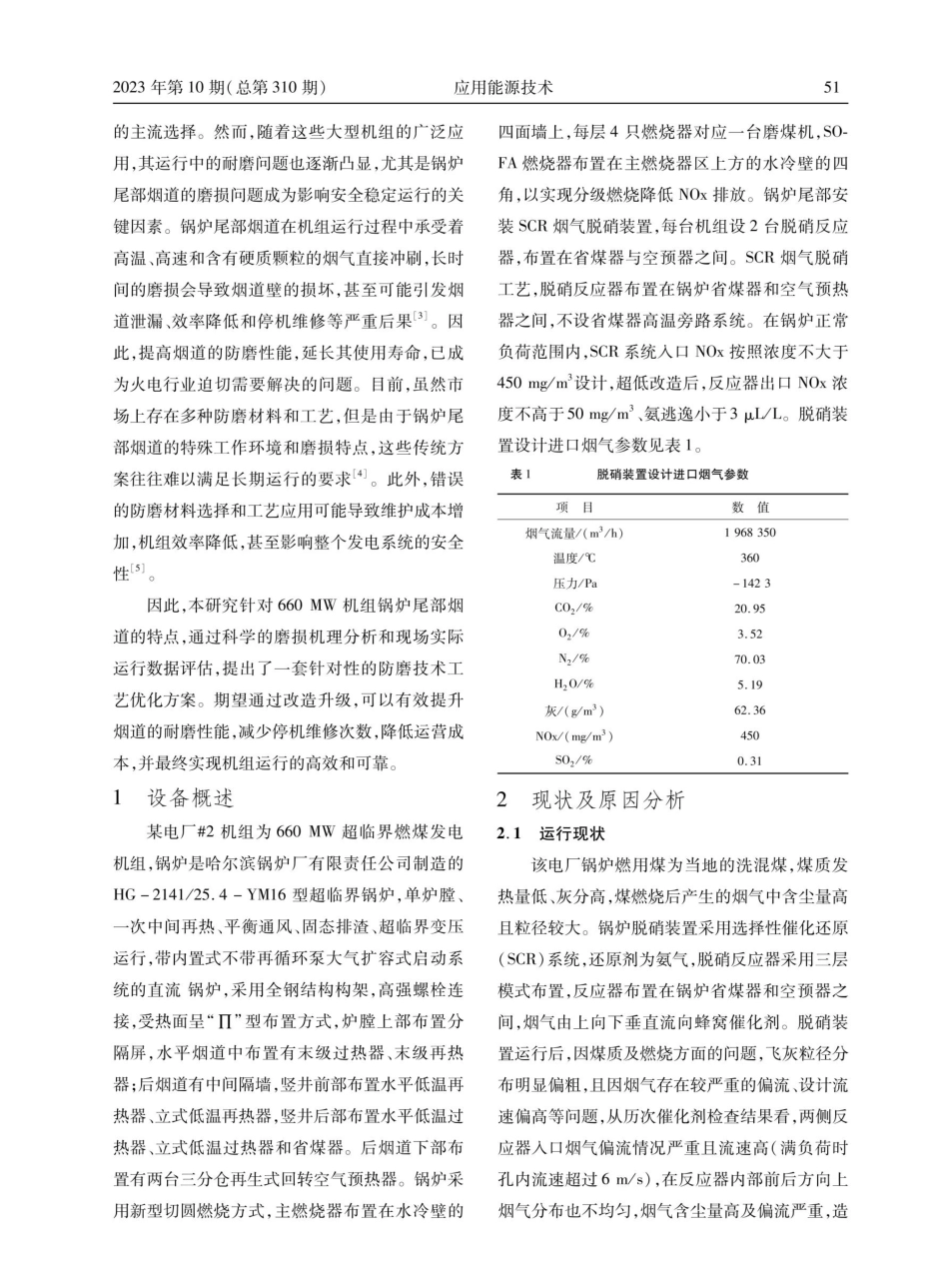

50doi:10.3969/j.issn.1009-3230.2023.10.011应用能源技术2023年第10期(总第310期)660MW机组锅炉尾部烟道防磨技术工艺优化改造苏小松(贵州能源集团电力投资有限公司,贵州贵阳550081)摘要:文中针对某660MW机组锅炉尾部烟道在运行过程中面临高温高速烟气及飞灰颗粒的冲刷,长期以来存在的磨损问题,提出锅炉尾部烟道采用新型的扩口烟风道结构进行优化,同时采用飞灰大颗粒捕捉技术,将捕捉到的大颗粒飞灰向外输送,减少飞灰对催化剂烟道壁的磨损的改造方案,优化改造实施后初步运行结果表明,脱硝系统烟气中的飞灰粒径明显减小,经性能考核试验结果得出,由省煤器灰斗及粗颗粒捕集装置的收灰率由5%提升至26.5%,脱硝还原剂液氨消耗量下降10%,脱硝系统阻力下降224Pa,空预器差压下降500Pa。通过此次的工艺优化改造烟道内件及催化剂的磨损问题得到根本性改善,为机组的安全性提供了有力保障。关键词:尾部烟道;防磨技术;颗粒捕集;脱硝系统中图分类号:TM621OptimizationandRetrofitofWear-resistantTechnologyintheTailFlueof660MWUnitBoiler(GuizhouEnergyGroupPowerInvestmentCo.Ltd.,Guiyang550081,China)Abstract:Thispaperaddressestheissueofwearinthetailflueof660MWunitboiler,causedbytheerosionofhigh-temperature,high-speedfluegasandflyingashparticlesduringoperation.Theproposedsolutioninvolvesoptimizingtheboiler'stailfluebyadoptinganovelexpansion-typefluegasductstructure.Simultaneously,atechnologyforcapturinglarge-sizedflyashparticlesisemployedtotransportthecapturedlargeparticlesexternally,reducingwearonthecatalystandfluewall.Preliminaryoperationalresultsaftertheoptimizationandretrofittingindicateasignificantreductioninflyashparticlesizeinthefluegasfromthedenitrificationsystem.Performanceassessmenttestresultsshowthattheashcollectionratefromtheeconomizerashhopperandcoarseparticlecollectiondeviceincreasedfrom5%to26.5%.Additionally,theammoniaconsumptionfordenitrificationdecreasedby10%,theresistanceofthedenitrificationsystemdecreasedby224Pa,andthedifferentialpressureoftheairpreheaterdecreasedby500Pa.Thisprocessoptimizationandretrofittinghavefundamentallyimprovedthewearissuesintheinternalcomponentsandcatalystoftheflue,providingstrongassurancefort...