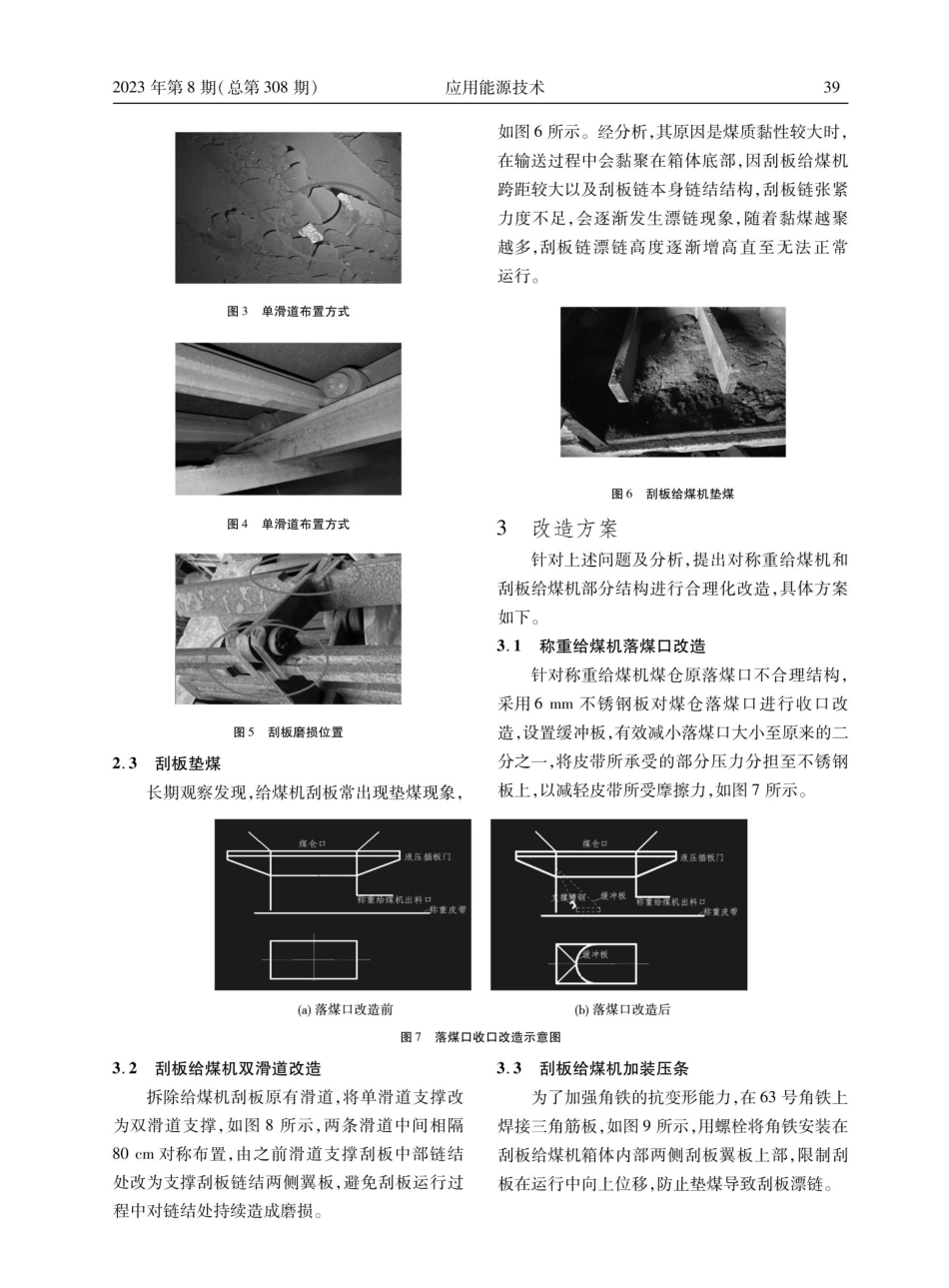

2023年第8期(总第308期)doi:10.3969/j.issn.1009-3230.2023.08.008应用能源技术37300MW循环流化床锅炉给煤系统优化改造袁莉星(云南能投红河发电有限公司,云南开远661699)摘要:文中针对某2×300MW机组1、2号炉投运以来,给煤系统常出现皮带磨损、刮板断裂、刮板垫煤、落煤口下煤不畅等缺陷,导致分离器超温。通过对给煤系统称重给煤机及刮板给煤机的结构、运行方式等进行分析,找到了导致上述缺陷产生的原因为:称重给煤机进煤口截面较大;刮板给煤机内部结构布置不合理。因此,针对该问题,公司相关技术人员提出对给没系统优化改造的方案。通过长周期运行观察并统计了1、2号炉4条称重给煤机皮带磨损更换数量、刮板断链次数及刮板垫煤次数进行对比分析,结果显示,改造取得显著效果。关键词:给煤系统;刮板给煤机;称重给煤机;磨损;垫煤中图分类号:TM621.2OptimizationandRetrofitoftheCoalFeedingSystemfor300MWCirculatingFluidizedBedBoiler(YunnanNengtouHonghePowerGenerationCo.Ltd.,Kaiyuan661699,China)Abstract:Thispaperaddressesissuesinthecoalfeedingsystemofthelstand2ndboilersof2x300MWunitsincetheircommissioning.Commonproblemssuchasbeltwear,scraperbreakage,coalcushioningonthescraper,andcoalblockagebelowthecoalchutehaveledtooverheatingoftheseparator.Throughananalysisofthestructureandoperationoftheweighingcoalfeederandscrapercoalfeederinthecoalfeedingsystem,thecausesofthementioneddefectswereidentified:theinletcross-sectionoftheweighingcoalfeederistoolarge,andtheinternalstructurearrangementofthescrapercoalfeederisunreasonable.Therefore,toaddresstheseissues,thecompany'stechnicalpersonnelproposedaschemeforoptimizingandretrofittingthecoalfeedingsystem.Byobservingandstatisticallyanalyzingthereplacementquantityofwornbelts,thenumberofscraperchainbreakages,andinstancesofcoalcushioningforfourweighingcoalfeedersonboilers1and2overanextendedoperatingperiod,theresultsshowedasignificantimprovementaftertheretrofit.Keywords:coalfeedingsystem;scrapercoalfeeder;weighingcoalfeeder;wear;coalcushioning00引言某公司现有2×300MW循环流化床(CFB)机组,锅炉由哈尔滨锅炉厂有限责任公司采用法国ALSTOM公司技术设计的HG-1025/17.5-L.HM37型CFB锅炉,出力1025t/h...