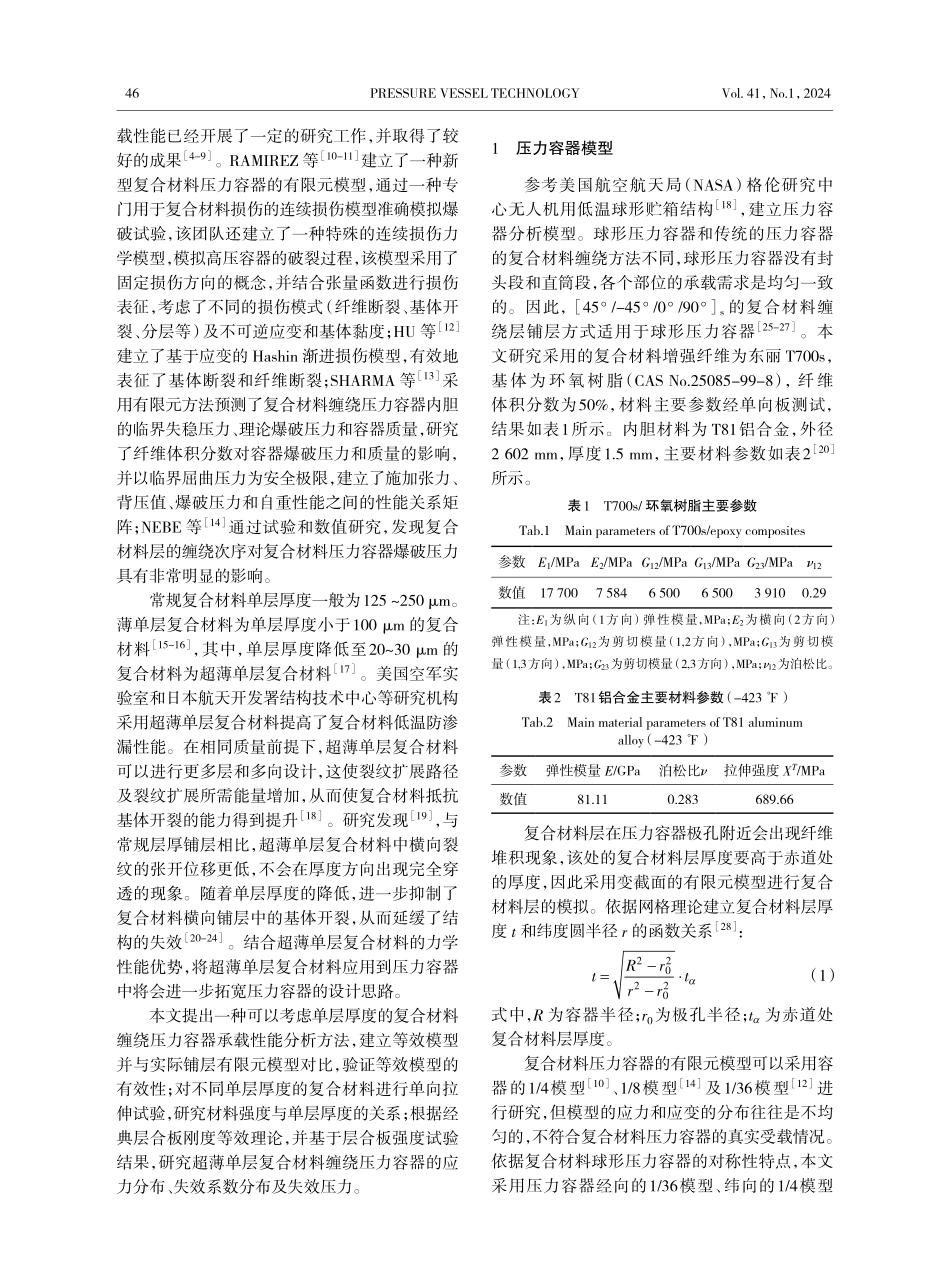

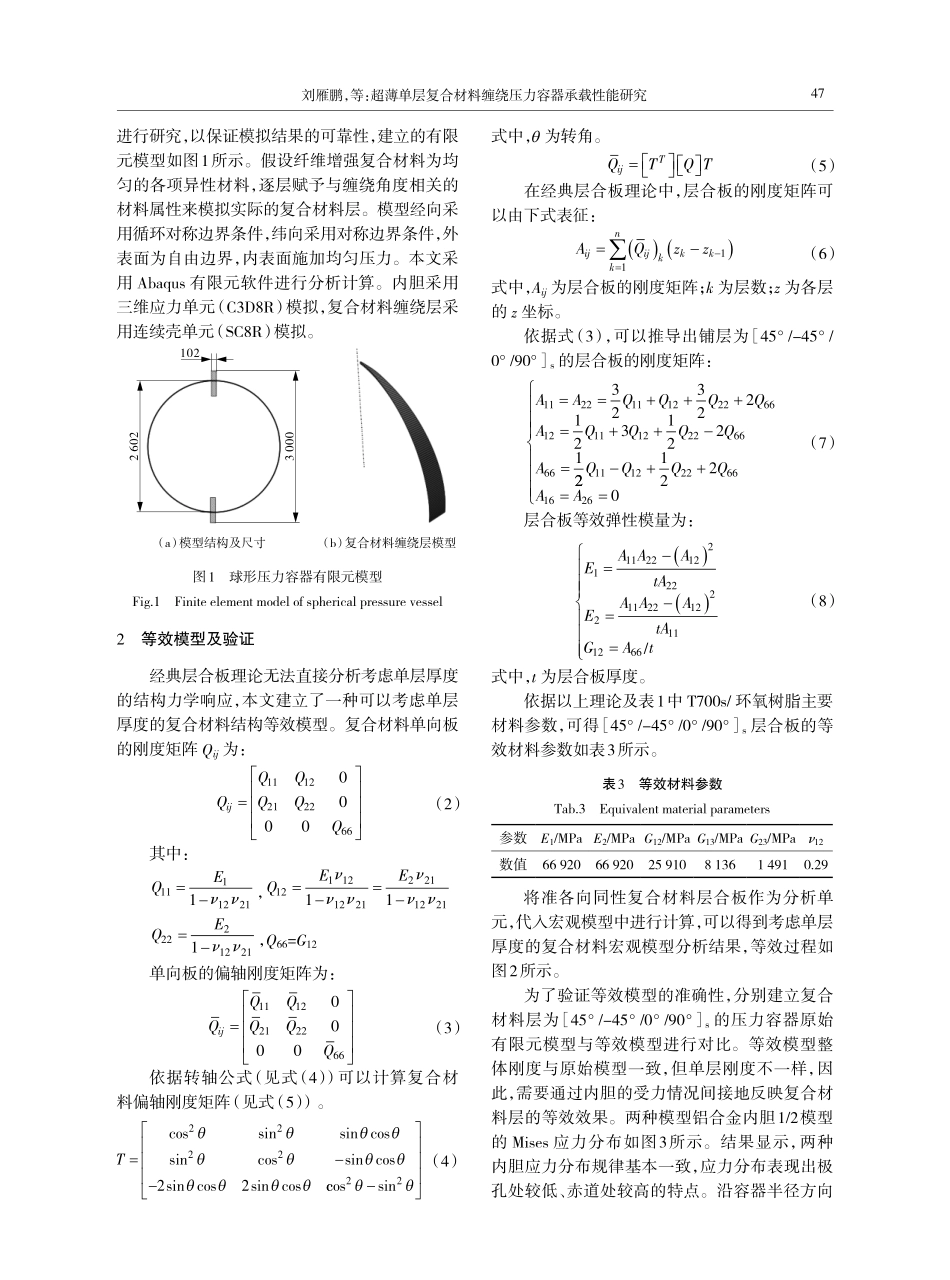

压力容器第41卷第1期2024年1月45收稿日期:2023-11-11修稿日期:2024-01-11基金项目:国家自然科学基金项目(12272078);科技领军人才团队专题项目(DUT22LAB503);大连市科技创新基金项目(2020JJ25CY011)doi:10.3969/j.issn.1001-4837.2024.01.006设计计算超薄单层复合材料缠绕压力容器承载性能研究刘雁鹏1,任中杰1,韩宇泽1,任明法2(1.大连理工大学工程力学系,辽宁大连116024;2.大连理工大学机械工程学院,辽宁大连116024)摘要:针对压力容器承载性能,基于经典层合板刚度等效理论,提出了一种可以考虑复合材料缠绕层单层厚度的压力容器承载性能分析方法;与实际铺层有限元模型进行对比,验证了分析方法的有效性;对不同单层厚度的复合材料进行了单向拉伸试验,获得材料强度与单层厚度的关系;分析了超薄单层复合材料缠绕压力容器的应力分布、失效系数分布及失效压力。结果表明,超薄单层复合材料缠绕压力容器的应力和损伤分布更为均匀,失效内压较常规单层厚度复合材料可提高54.5%。该研究成果可为超薄单层复合材料缠绕压力容器的结构设计提供可靠的理论参考。关键词:压力容器;超薄单层复合材料;单层厚度;强度;失效内压中图分类号:TH49;O342;O241文献标志码:AResearchontheloadbearingperformanceofultra-thin-plycompositewoundpressurevesselsLIUYanpeng1,RENZhongjie1,HANYuze1,RENMingfa2(1.DepartmentofEngineeringMechanics,DalianUniversityofTechnology,Dalian116024,China;2.SchoolofMechanicalEngineering,DalianUniversityofTechnology,Dalian116024,China)Abstract:Ananalysismethodwasproposedfortheloadbearingperformanceofpressurevesselsthattakesintoaccounttheplythicknessofthecompositewindinglayerbasedontheclassicallaminateplatestiffnessequivalenttheory.Acomparisonwithactuallayupfiniteelementmodelswascarriedout,whichverifiestheeffectivenessoftheanalysismethod.Uniaxialtensiletestswereconductedondifferentplythicknessesofthecompositestoobtainedtherelationshipbetweenmaterialstrengthandplythickness.Thestressdistribution,failurecoefficientdistribution,andfailurepressureofultra-thin-plycompositewoundpressurevesselswereanalyzed.Resultsshowthatboththestressanddamagedistributionsofultra-thin-plycompositewoundpressurevesselsaremore...