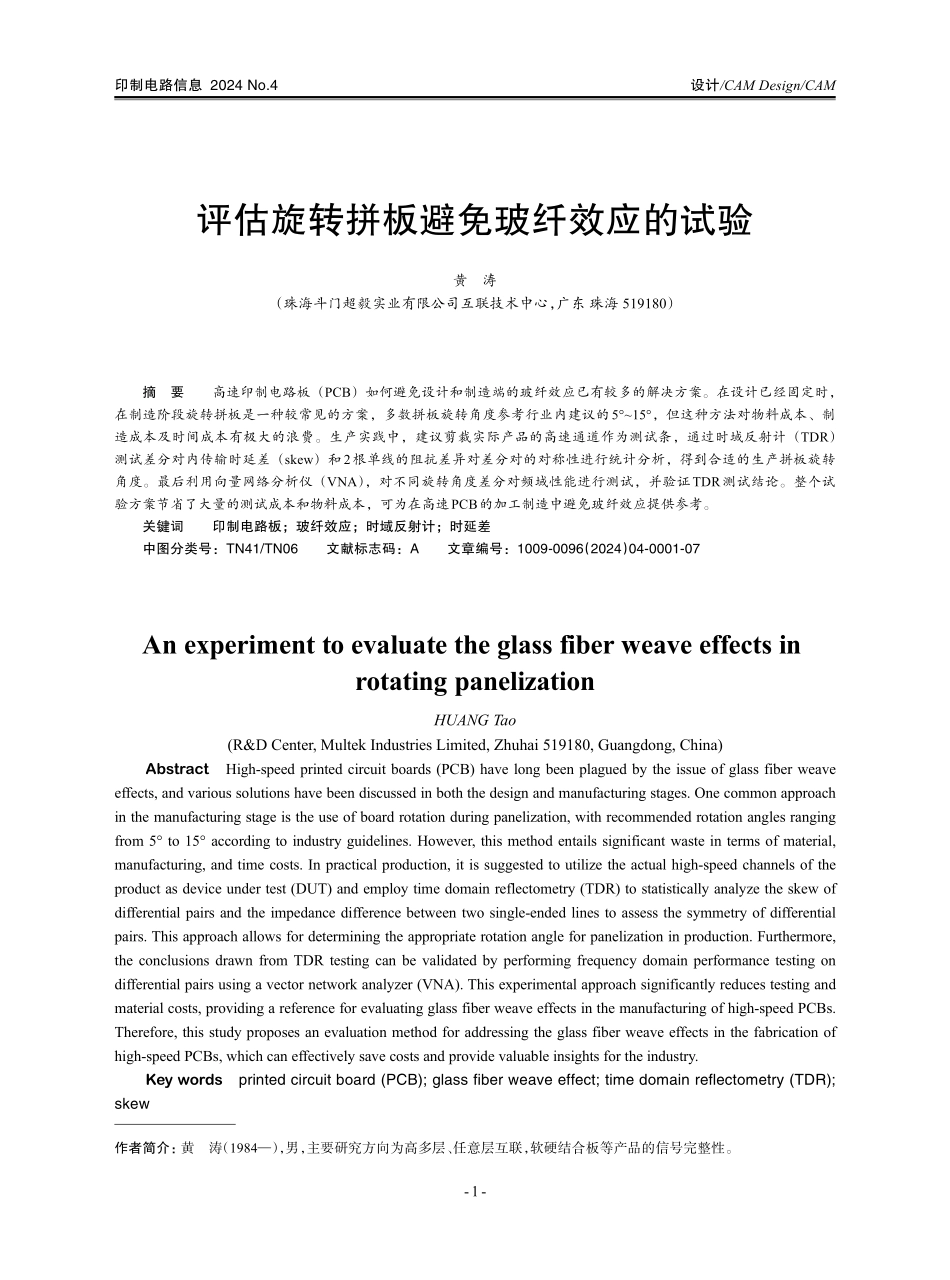

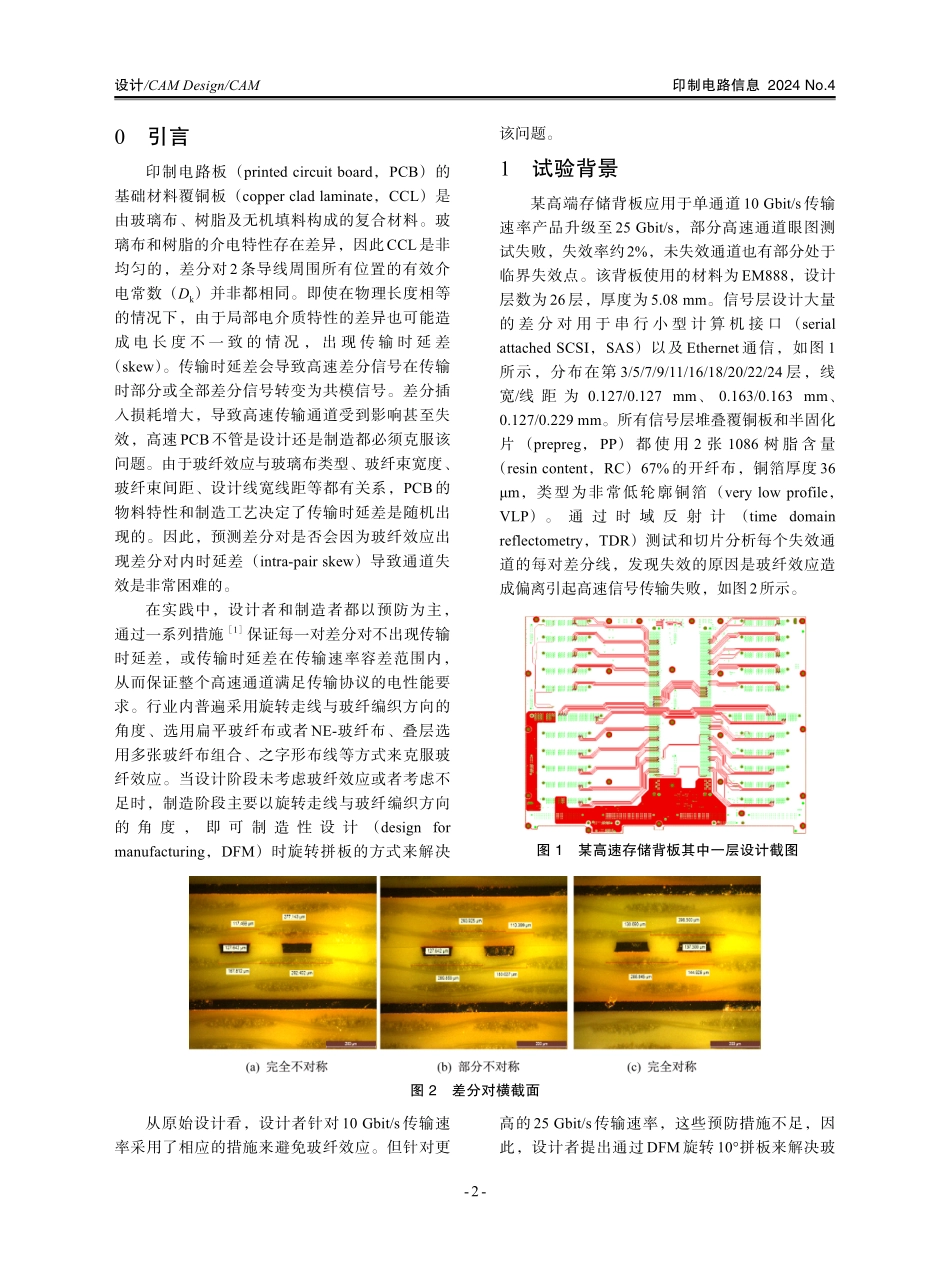

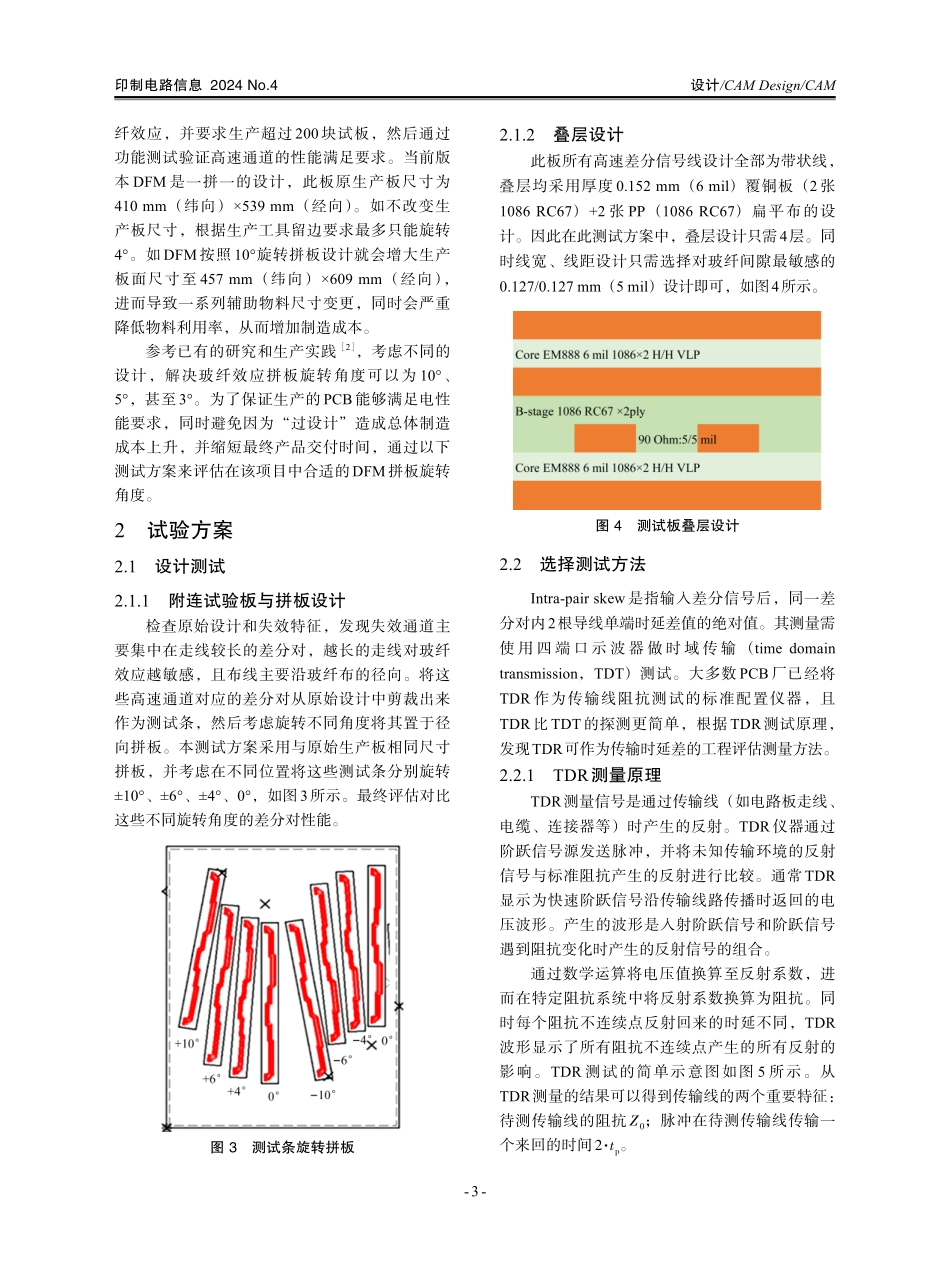

印制电路信息2024No.4设计/CAMDesign/CAM评估旋转拼板避免玻纤效应的试验黄涛(珠海斗门超毅实业有限公司互联技术中心,广东珠海519180)摘要高速印制电路板(PCB)如何避免设计和制造端的玻纤效应已有较多的解决方案。在设计已经固定时,在制造阶段旋转拼板是一种较常见的方案,多数拼板旋转角度参考行业内建议的5°~15°,但这种方法对物料成本、制造成本及时间成本有极大的浪费。生产实践中,建议剪裁实际产品的高速通道作为测试条,通过时域反射计(TDR)测试差分对内传输时延差(skew)和2根单线的阻抗差异对差分对的对称性进行统计分析,得到合适的生产拼板旋转角度。最后利用向量网络分析仪(VNA),对不同旋转角度差分对频域性能进行测试,并验证TDR测试结论。整个试验方案节省了大量的测试成本和物料成本,可为在高速PCB的加工制造中避免玻纤效应提供参考。关键词印制电路板;玻纤效应;时域反射计;时延差中图分类号:TN41/TN06文献标志码:A文章编号:1009⁃0096(2024)04⁃0001⁃07AnexperimenttoevaluatetheglassfiberweaveeffectsinrotatingpanelizationHUANGTao(R&DCenter,MultekIndustriesLimited,Zhuhai519180,Guangdong,China)AbstractHigh-speedprintedcircuitboards(PCB)havelongbeenplaguedbytheissueofglassfiberweaveeffects,andvarioussolutionshavebeendiscussedinboththedesignandmanufacturingstages.Onecommonapproachinthemanufacturingstageistheuseofboardrotationduringpanelization,withrecommendedrotationanglesrangingfrom5°to15°accordingtoindustryguidelines.However,thismethodentailssignificantwasteintermsofmaterial,manufacturing,andtimecosts.Inpracticalproduction,itissuggestedtoutilizetheactualhigh-speedchannelsoftheproductasdeviceundertest(DUT)andemploytimedomainreflectometry(TDR)tostatisticallyanalyzetheskewofdifferentialpairsandtheimpedancedifferencebetweentwosingle-endedlinestoassessthesymmetryofdifferentialpairs.Thisapproachallowsfordeterminingtheappropriaterotationangleforpanelizationinproduction.Furthermore,theconclusionsdrawnfromTDRtestingcanbevalidatedbyperformingfrequencydomainperformancetestingondifferentialpairsusingavectornetworkanalyzer(VNA).Thisexperimentalapproachsignificantlyreducestestingandmaterialcosts,providingarefe...