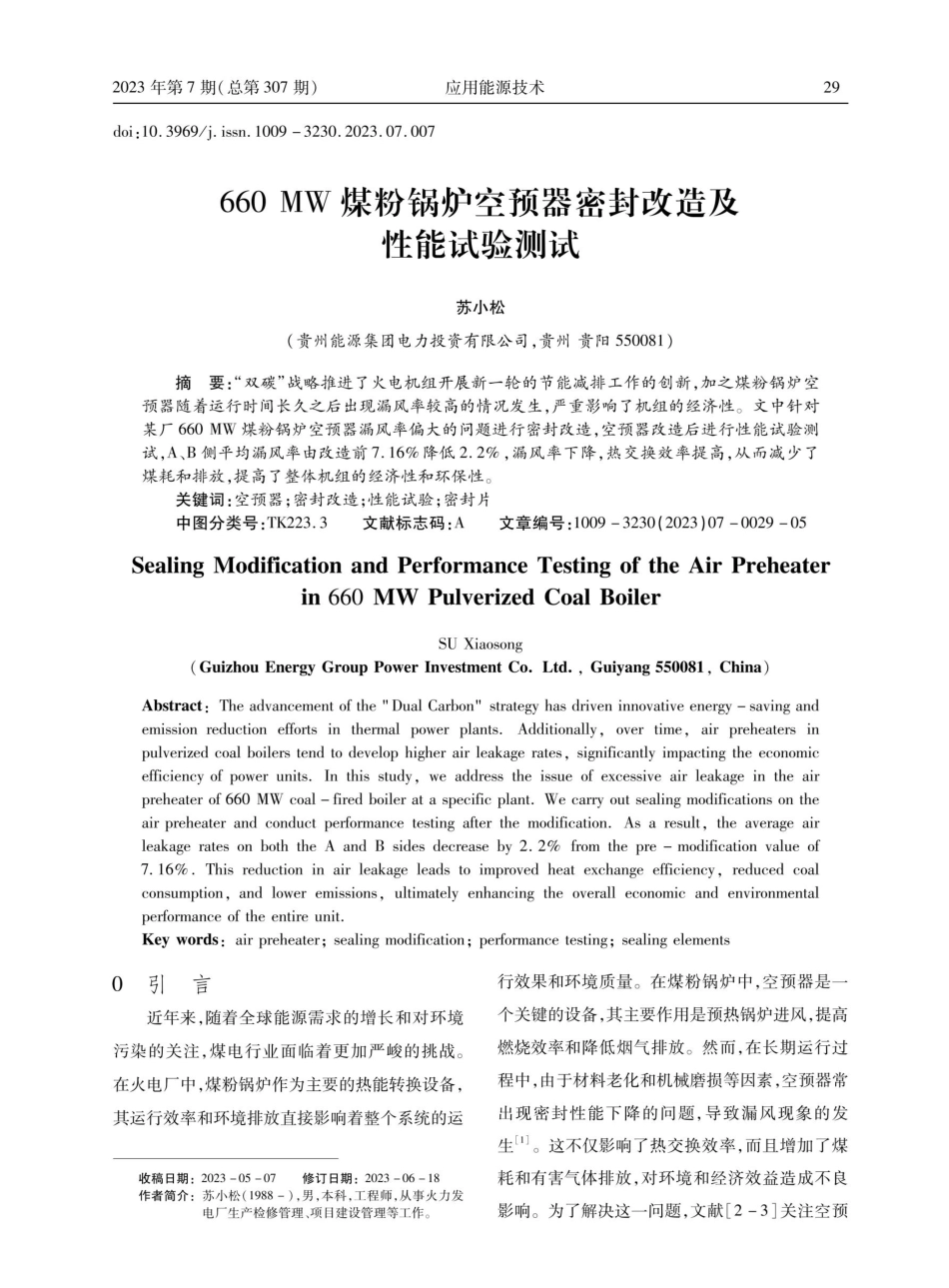

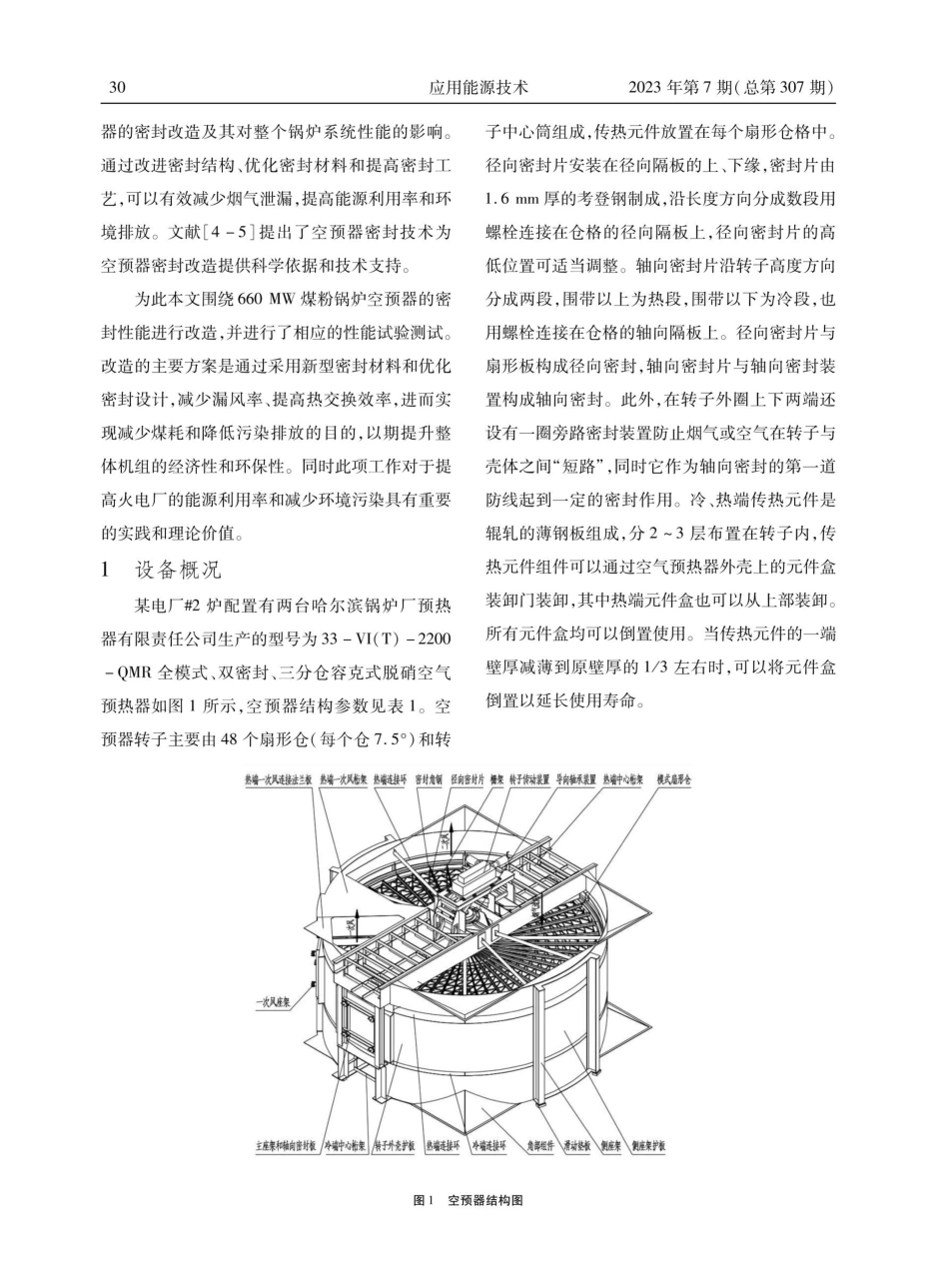

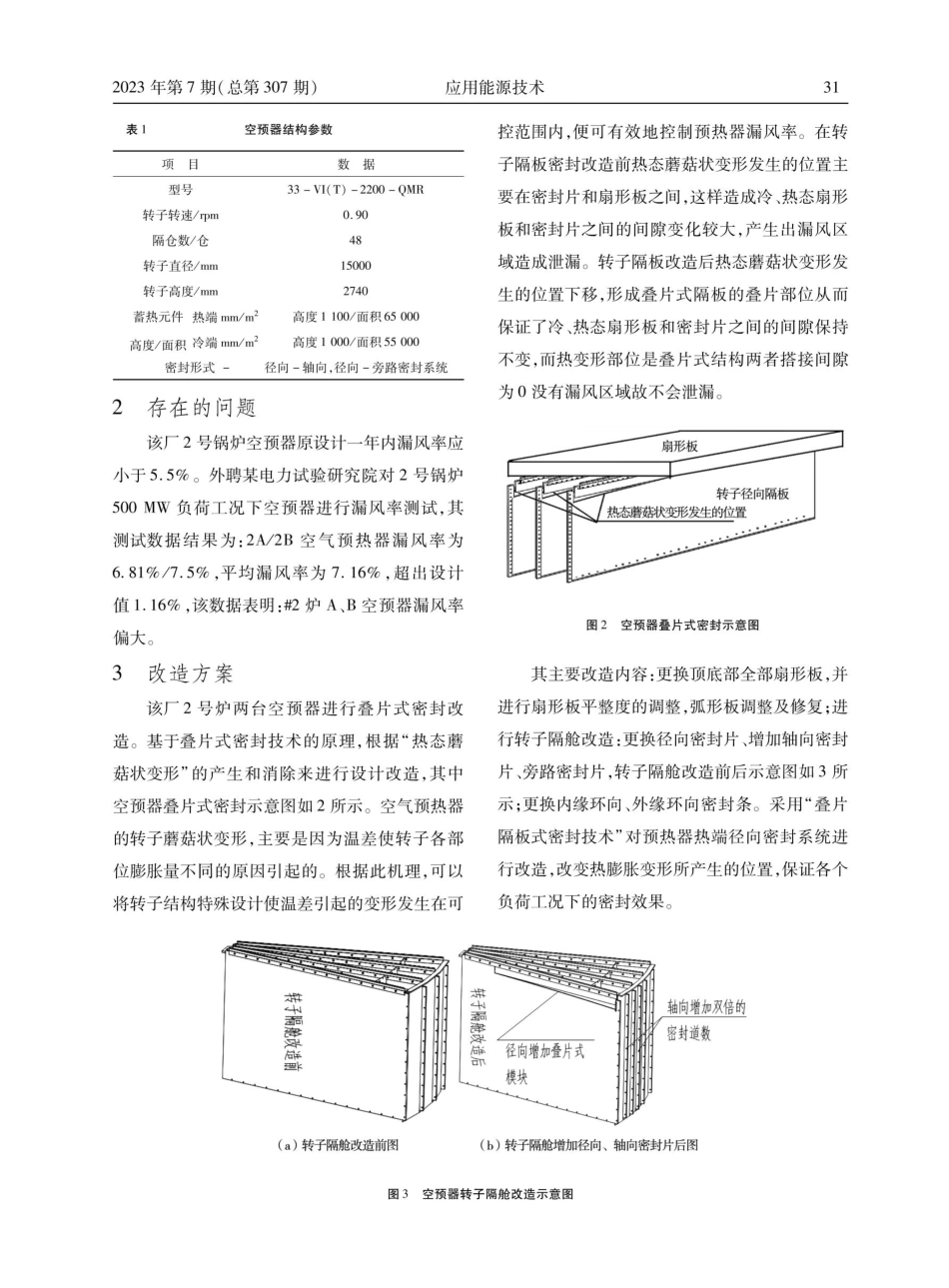

2023年第7期(总第307期)doi:10.3969/j.issn.1009-3230.2023.07.007应用能源技术29660MW煤粉锅炉空预器密封改造及性能试验测试苏小松(贵州能源集团电力投资有限公司,贵州贵阳550081)摘要:“双碳”战略推进了火电机组开展新一轮的节能减排工作的创新,加之煤粉锅炉空预器随着运行时间长久之后出现漏风率较高的情况发生,严重影响了机组的经济性。文中针对某厂660MW煤粉锅炉空预器漏风率偏大的问题进行密封改造,空预器改造后进行性能试验测试,A、B侧平均漏风率由改造前7.16%降低2.2%,漏风率下降,热交换效率提高,从而减少了煤耗和排放,提高了整体机组的经济性和环保性。关键词:空预器;密封改造;性能试验;密封片中图分类号:TK223.3SealingModificationandPerformanceTestingoftheAirPreheater(GuizhouEnergyGroupPowerInvestmentCo.Ltd.,Guiyang550081,China)Abstract:Theadvancementofthe"DualCarbon"strategyhasdriveninnovativeenergy-savingandemissionreductioneffortsinthermalpowerplants.Additionally,overtime,airpreheatersinpulverizedcoalboilerstendtodevelophigherairleakagerates,significantlyimpactingtheeconomicefficiencyofpowerunits.Inthisstudy,weaddresstheissueofexcessiveairleakageintheairpreheaterof660MWcoal-firedboilerataspecificplant.Wecarryoutsealingmodificationsontheairpreheaterandconductperformancetestingafterthemodification.Asaresult,theaverageairleakageratesonboththeAandBsidesdecreaseby2.2%fromthepre-modificationvalueof7.16%.Thisreductioninairleakageleadstoimprovedheatexchangeefficiency,reducedcoalconsumption,andloweremissions,ultimatelyenhancingtheoveralleconomicandenvironmentalperformanceoftheentireunit.Keywords:airpreheater;sealingmodification;performancetesting;sealingelements0引言近年来,随着全球能源需求的增长和对环境污染的关注,煤电行业面临着更加严峻的挑战。在火电厂中,煤粉锅炉作为主要的热能转换设备,其运行效率和环境排放直接影响着整个系统的运收稿日期:2023-05-07修订日期:2023-06-18作者简介:苏小松(1988-),男,本科,工程师,从事火力发电厂生产检修管理、项目建设管理等工作。文献标志码:Ain660MWPulverizedCoalBoilerSUXiaosong行效果和环境质量。在煤粉锅炉中,空预器是一个关键的设备,,其主要作用是预热锅炉进风,...