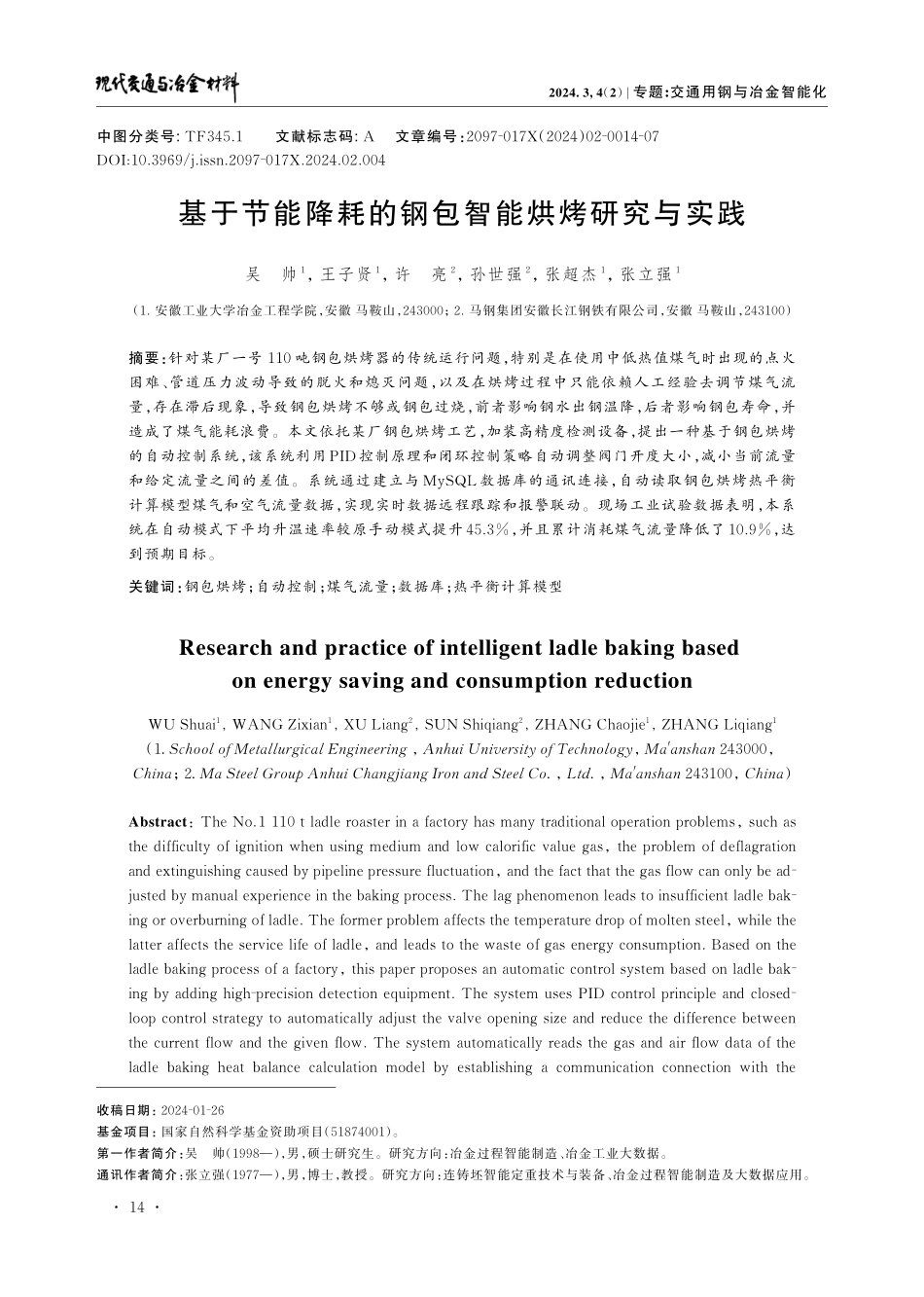

2024.3,4(2)|专题:交通用钢与冶金智能化基于节能降耗的钢包智能烘烤研究与实践吴帅1,王子贤1,许亮2,孙世强2,张超杰1,张立强1(1.安徽工业大学冶金工程学院,安徽马鞍山,243000;2.马钢集团安徽长江钢铁有限公司,安徽马鞍山,243100)摘要:针对某厂一号110吨钢包烘烤器的传统运行问题,特别是在使用中低热值煤气时出现的点火困难、管道压力波动导致的脱火和熄灭问题,以及在烘烤过程中只能依赖人工经验去调节煤气流量,存在滞后现象,导致钢包烘烤不够或钢包过烧,前者影响钢水出钢温降,后者影响钢包寿命,并造成了煤气能耗浪费。本文依托某厂钢包烘烤工艺,加装高精度检测设备,提出一种基于钢包烘烤的自动控制系统,该系统利用PID控制原理和闭环控制策略自动调整阀门开度大小,减小当前流量和给定流量之间的差值。系统通过建立与MySQL数据库的通讯连接,自动读取钢包烘烤热平衡计算模型煤气和空气流量数据,实现实时数据远程跟踪和报警联动。现场工业试验数据表明,本系统在自动模式下平均升温速率较原手动模式提升45.3%,并且累计消耗煤气流量降低了10.9%,达到预期目标。关键词:钢包烘烤;自动控制;煤气流量;数据库;热平衡计算模型ResearchandpracticeofintelligentladlebakingbasedonenergysavingandconsumptionreductionWUShuai1,WANGZixian1,XULiang2,SUNShiqiang2,ZHANGChaojie1,ZHANGLiqiang1(1.SchoolofMetallurgicalEngineering,AnhuiUniversityofTechnology,Ma'anshan243000,China;2.MaSteelGroupAnhuiChangjiangIronandSteelCo.,Ltd.,Ma'anshan243100,China)Abstract:TheNo.1110tladleroasterinafactoryhasmanytraditionaloperationproblems,suchasthedifficultyofignitionwhenusingmediumandlowcalorificvaluegas,theproblemofdeflagrationandextinguishingcausedbypipelinepressurefluctuation,andthefactthatthegasflowcanonlybead⁃justedbymanualexperienceinthebakingprocess.Thelagphenomenonleadstoinsufficientladlebak⁃ingoroverburningofladle.Theformerproblemaffectsthetemperaturedropofmoltensteel,whilethelatteraffectstheservicelifeofladle,andleadstothewasteofgasenergyconsumption.Basedontheladlebakingprocessofafactory,thispaperproposesanautomaticcontrolsystembasedonladlebak⁃ingbyaddinghigh-precisiondetectionequipment.ThesystemusesPIDcontrolprincipleandclosed...