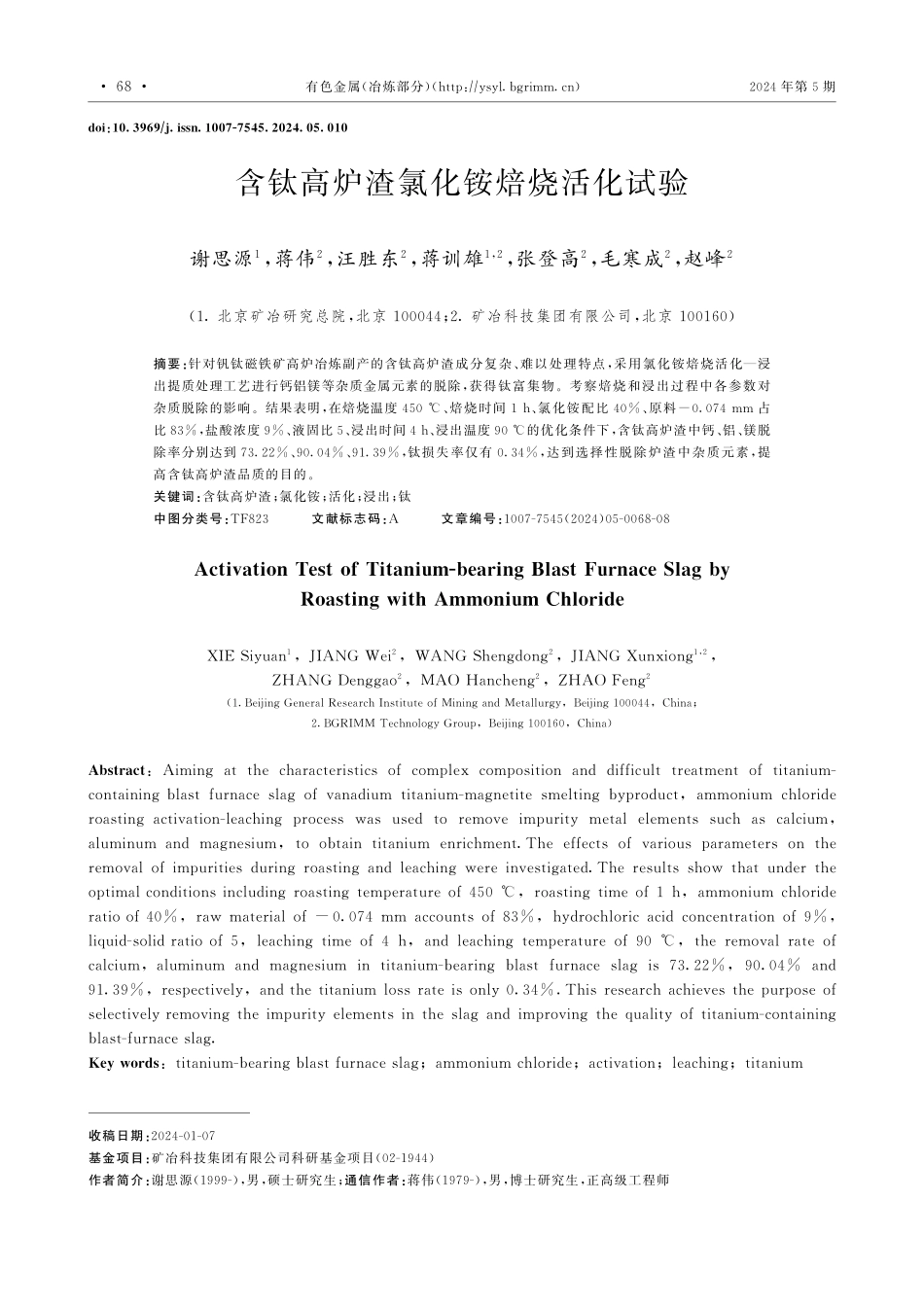

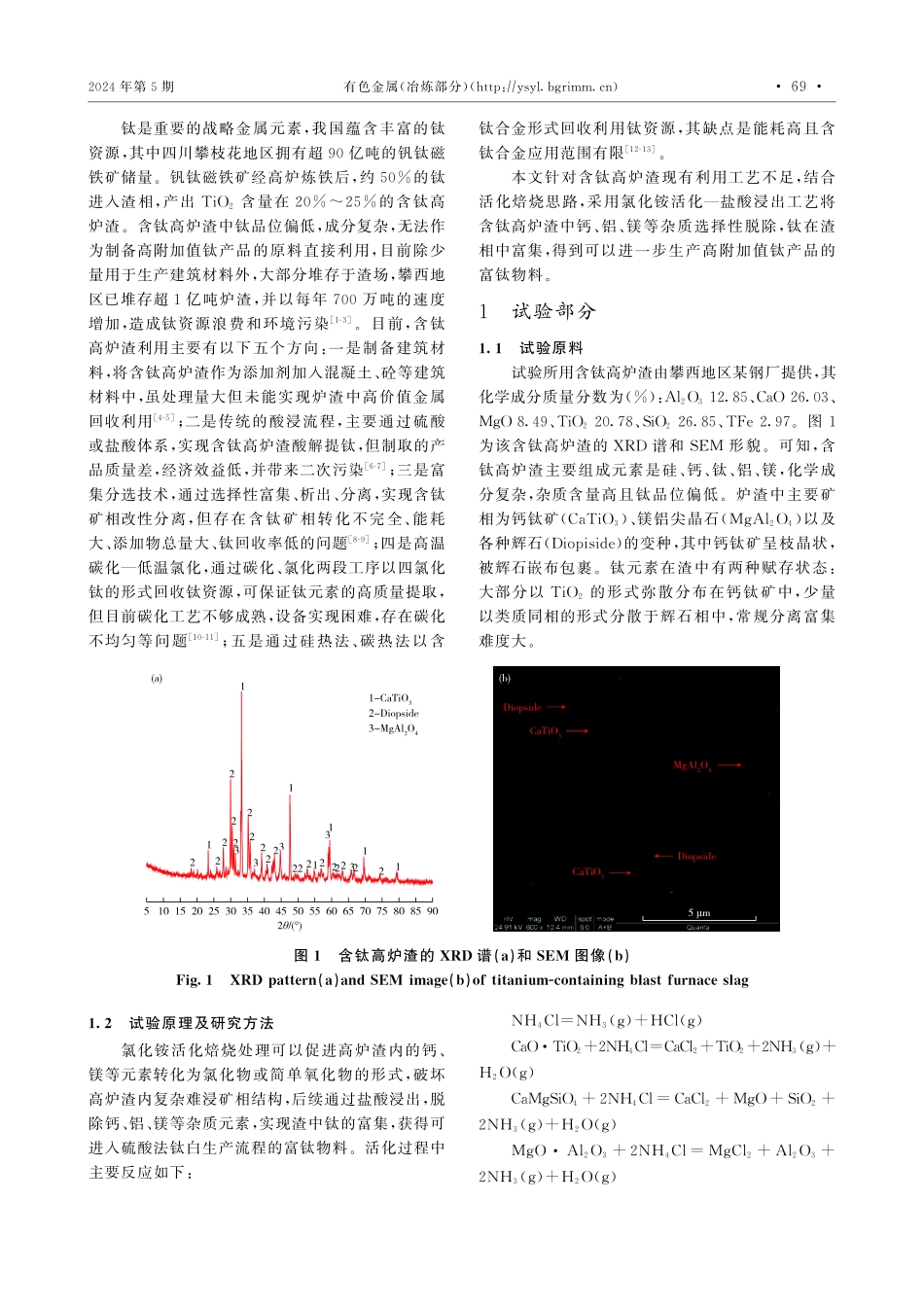

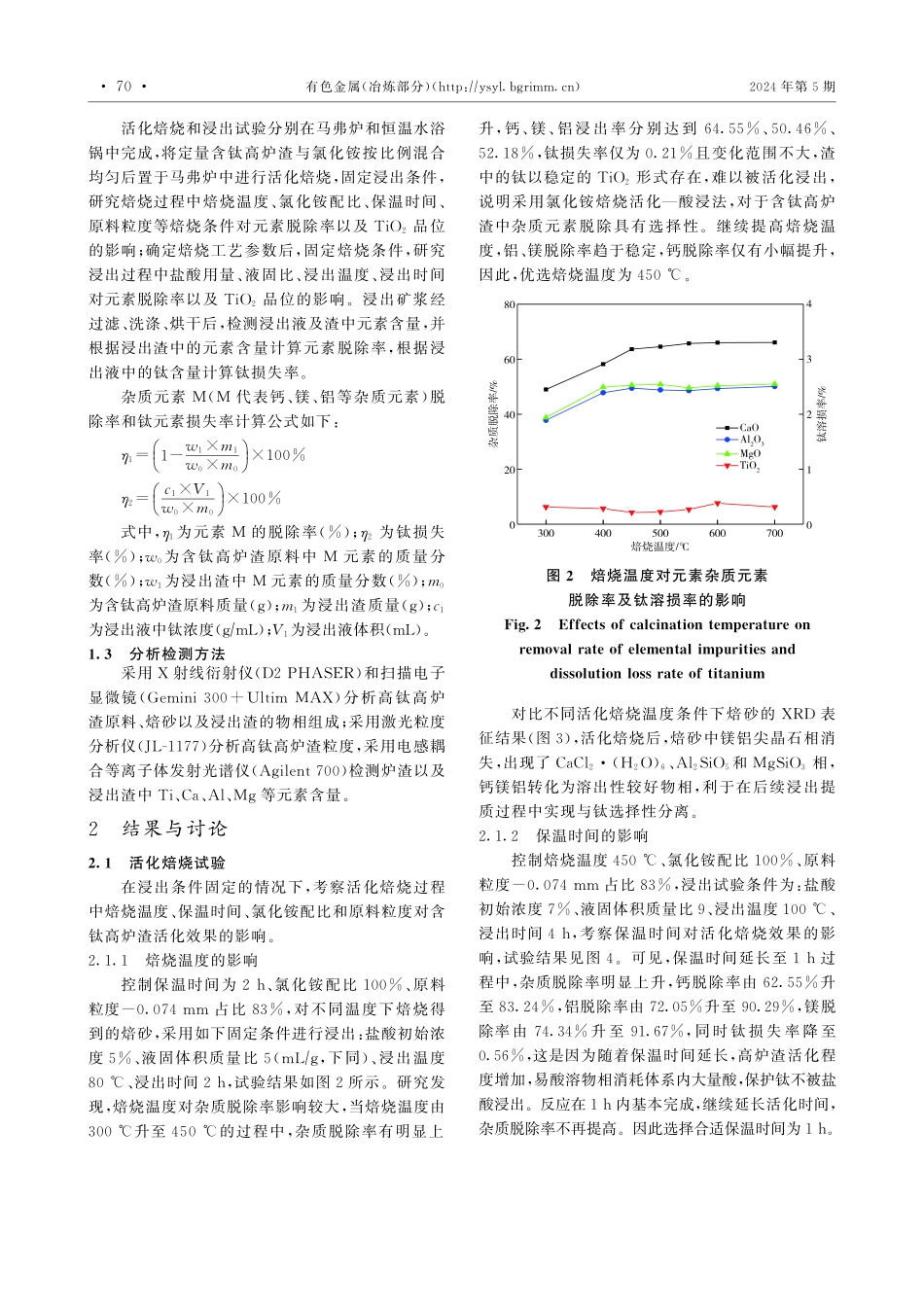

doi:103969∕jissn1007G7545202405010收稿日期:2024G01G07基金项目:矿冶科技集团有限公司科研基金项目(02G1944)作者简介:谢思源(1999G),男,硕士研究生;通信作者:蒋伟(1979G),男,博士研究生,正高级工程师含钛高炉渣氯化铵焙烧活化试验谢思源1,蒋伟2,汪胜东2,蒋训雄1,2,张登高2,毛寒成2,赵峰2(1北京矿冶研究总院,北京100044;2矿冶科技集团有限公司,北京100160)摘要:针对钒钛磁铁矿高炉冶炼副产的含钛高炉渣成分复杂、难以处理特点,采用氯化铵焙烧活化—浸出提质处理工艺进行钙铝镁等杂质金属元素的脱除,获得钛富集物.考察焙烧和浸出过程中各参数对杂质脱除的影响.结果表明,在焙烧温度450℃、焙烧时间1h、氯化铵配比40%、原料-0074mm占比83%,盐酸浓度9%、液固比5、浸出时间4h、浸出温度90℃的优化条件下,含钛高炉渣中钙、铝、镁脱除率分别达到7322%、9004%、9139%,钛损失率仅有034%,达到选择性脱除炉渣中杂质元素,提高含钛高炉渣品质的目的.关键词:含钛高炉渣;氯化铵;活化;浸出;钛中图分类号:TF823文献标志码:A文章编号:1007G7545(2024)05G0068G08ActivationTestofTitaniumGbearingBlastFurnaceSlagbyRoastingwithAmmoniumChlorideXIESiyuan1,JIANGWei2,WANGShengdong2,JIANGXunxiong1,2,ZHANGDenggao2,MAOHancheng2,ZHAOFeng2(1BeijingGeneralResearchInstituteofMiningandMetallurgy,Beijing100044,China;2BGRIMMTechnologyGroup,Beijing100160,China)Abstract:AimingatthecharacteristicsofcomplexcompositionanddifficulttreatmentoftitaniumGcontainingblastfurnaceslagofvanadiumtitaniumGmagnetitesmeltingbyproduct,ammoniumchlorideroastingactivationGleachingprocesswasusedtoremoveimpuritymetalelementssuchascalcium,aluminumandmagnesium,toobtaintitaniumenrichmentTheeffectsofvariousparametersontheremovalofimpuritiesduringroastingandleachingwereinvestigatedTheresultsshowthatundertheoptimalconditionsincludingroastingtemperatureof450℃,roastingtimeof1h,ammoniumchlorideratioof40%,rawmaterialof-0074mmaccountsof83%,hydrochloricacidconcentrationof9%,liquidGsolidratioof5,lea...