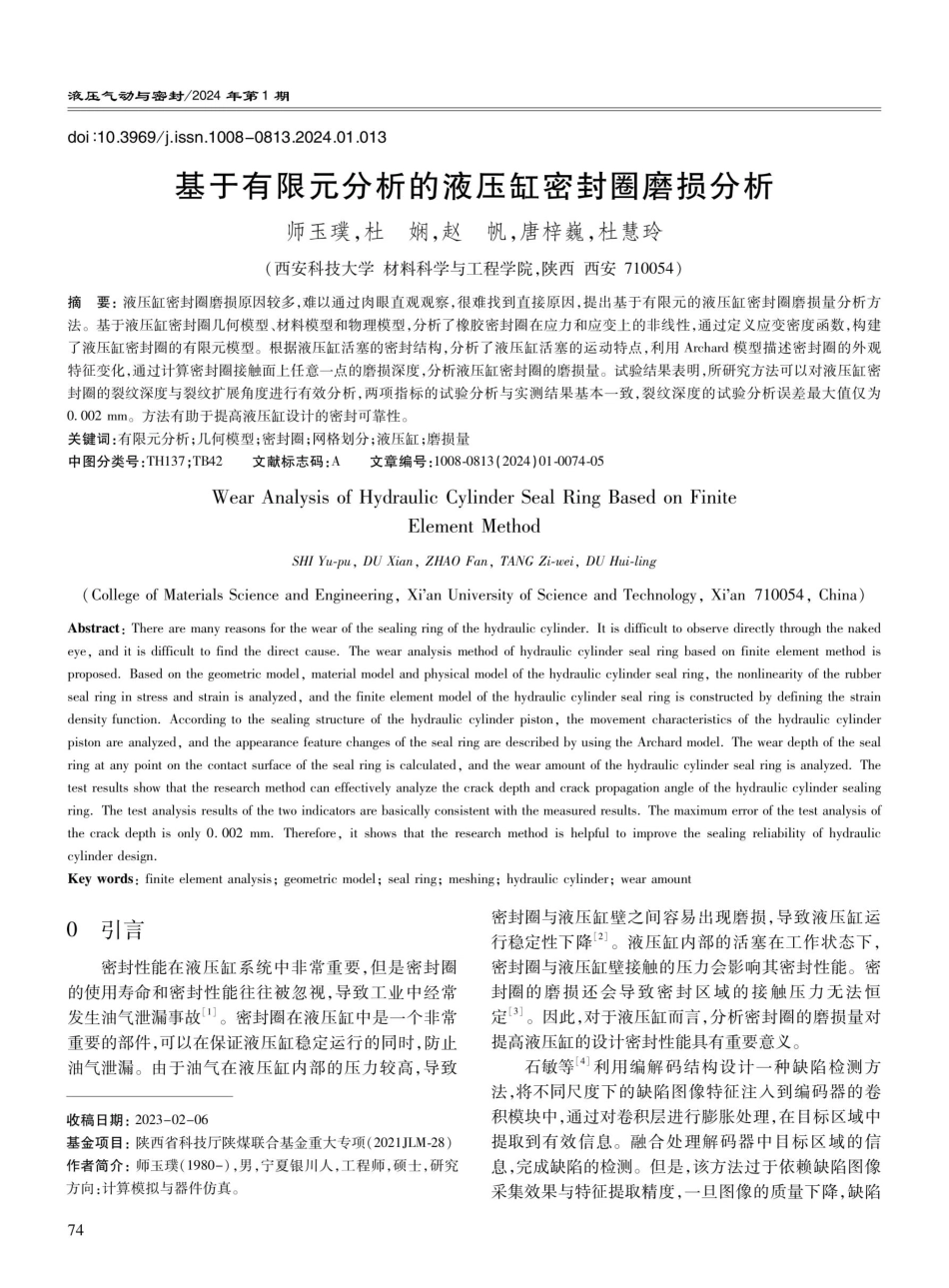

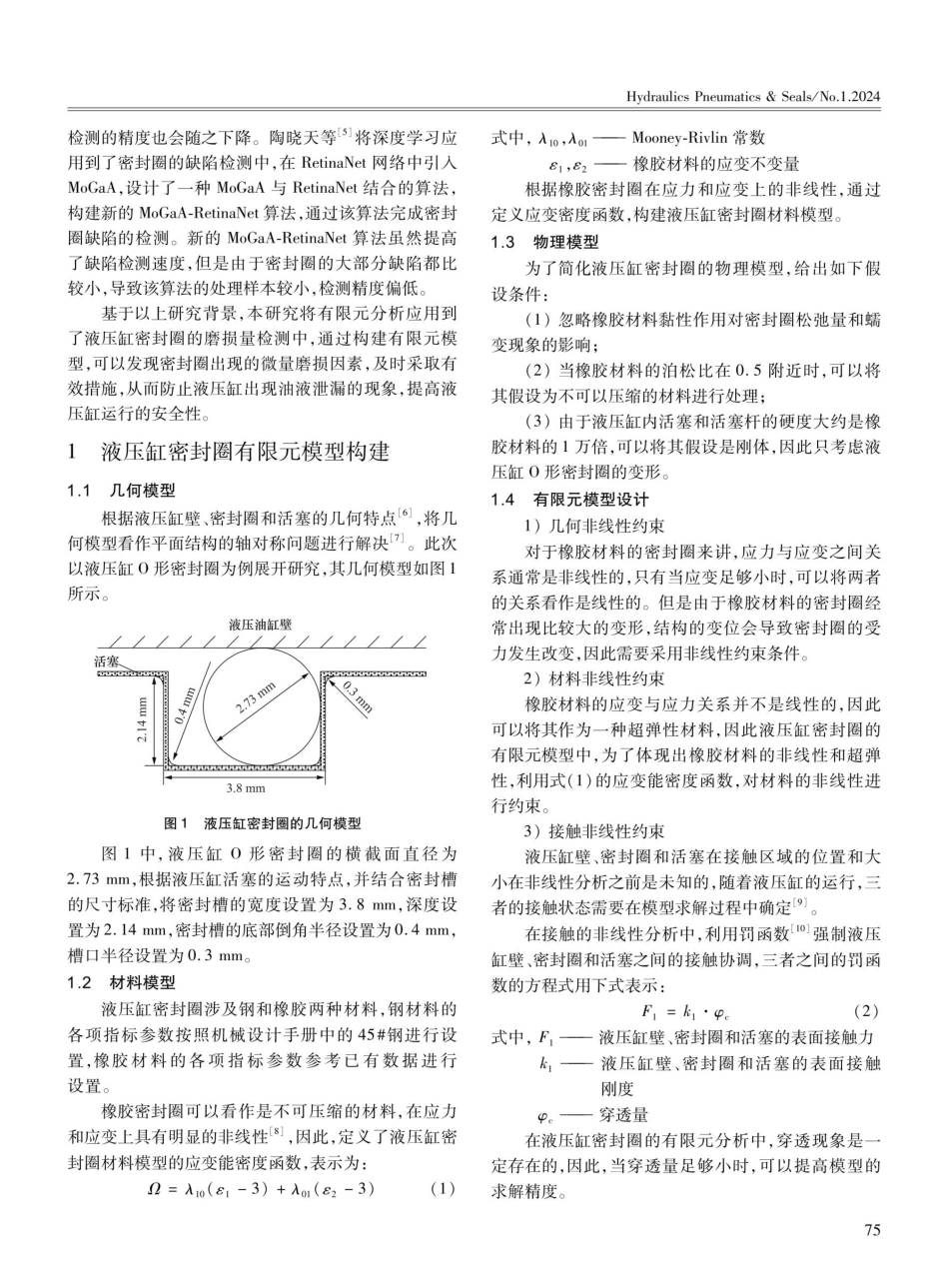

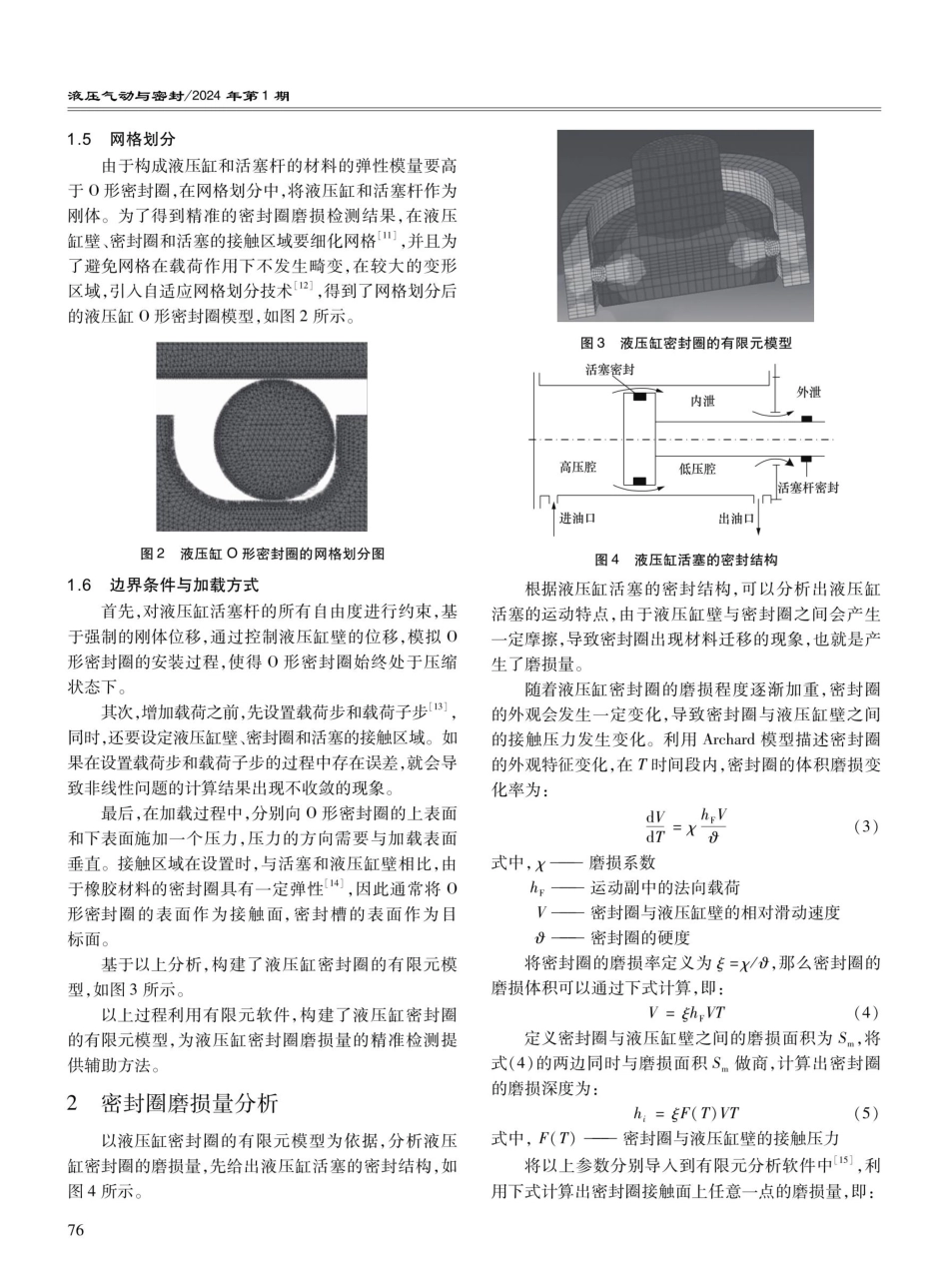

液压气动与密封/2024年第1期doi:10.3969/j.issn.1008-0813.2024.01.013基于有限元分析的液压缸密封圈磨损分析师玉璞,杜娴,赵帆,唐梓巍,杜慧玲(西安科技大学材料科学与工程学院,陕西西安710054)摘要:液压缸密封圈磨损原因较多,难以通过肉眼直观观察,很难找到直接原因,提出基于有限元的液压缸密封圈磨损量分析方法。基于液压缸密封圈几何模型、材料模型和物理模型,分析了橡胶密封圈在应力和应变上的非线性,通过定义应变密度函数,构建了液压缸密封圈的有限元模型。根据液压缸活塞的密封结构,分析了液压缸活塞的运动特点,利用Archard模型描述密封圈的外观特征变化,通过计算密封圈接触面上任意一点的磨损深度,分析液压缸密封圈的磨损量。试验结果表明,所研究方法可以对液压缸密封圈的裂纹深度与裂纹扩展角度进行有效分析,两项指标的试验分析与实测结果基本一致,裂纹深度的试验分析误差最大值仅为0.002mm。方法有助于提高液压缸设计的密封可靠性。关键词:有限元分析;几何模型;密封圈;网格划分;液压缸;磨损量中图分类号:TH137;TB42(CollegeofMaterialsScienceandEngineering,Xi'anUniversityofScienceandTechnology,Xi'an710054,China)Abstract:Therearemanyreasonsforthewearofthesealingringofthehydrauliccylinder.Itisdificulttoobservedirectlythroughthenakedeye,anditisdifficulttofindthedirectcause.Thewearanalysismethodofhydrauliccylindersealringbasedonfiniteelementmethodisproposed.Basedonthegeometricmodel,materialmodelandphysicalmodelofthehydrauliccylindersealring,thenonlinearityoftherubbersealringinstressandstrainisanalyzed,andthefiniteelementmodelofthehydrauliccylindersealringisconstructedbydefiningthestraindensityfunction.Accordingtothesealingstructureofthehydrauliccylinderpiston,themovementcharacteristicsofthehydrauliccylinderpistonareanalyzed,andtheappearancefeaturechangesofthesealringaredescribedbyusingtheArchardmodel.Theweardepthofthesealringatanypointonthecontactsurfaceofthesealringiscalculated,andthewearamountofthehydrauliccylindersealringisanalyzed.Thetestresultsshowthattheresearchmethodcaneffectivelyanalyzethecrackdepthandcrackpropagationangleofthehydrauliccylindersealingring.Thetestanalysisresultsofthetwoindicatorsarebasicallyc...