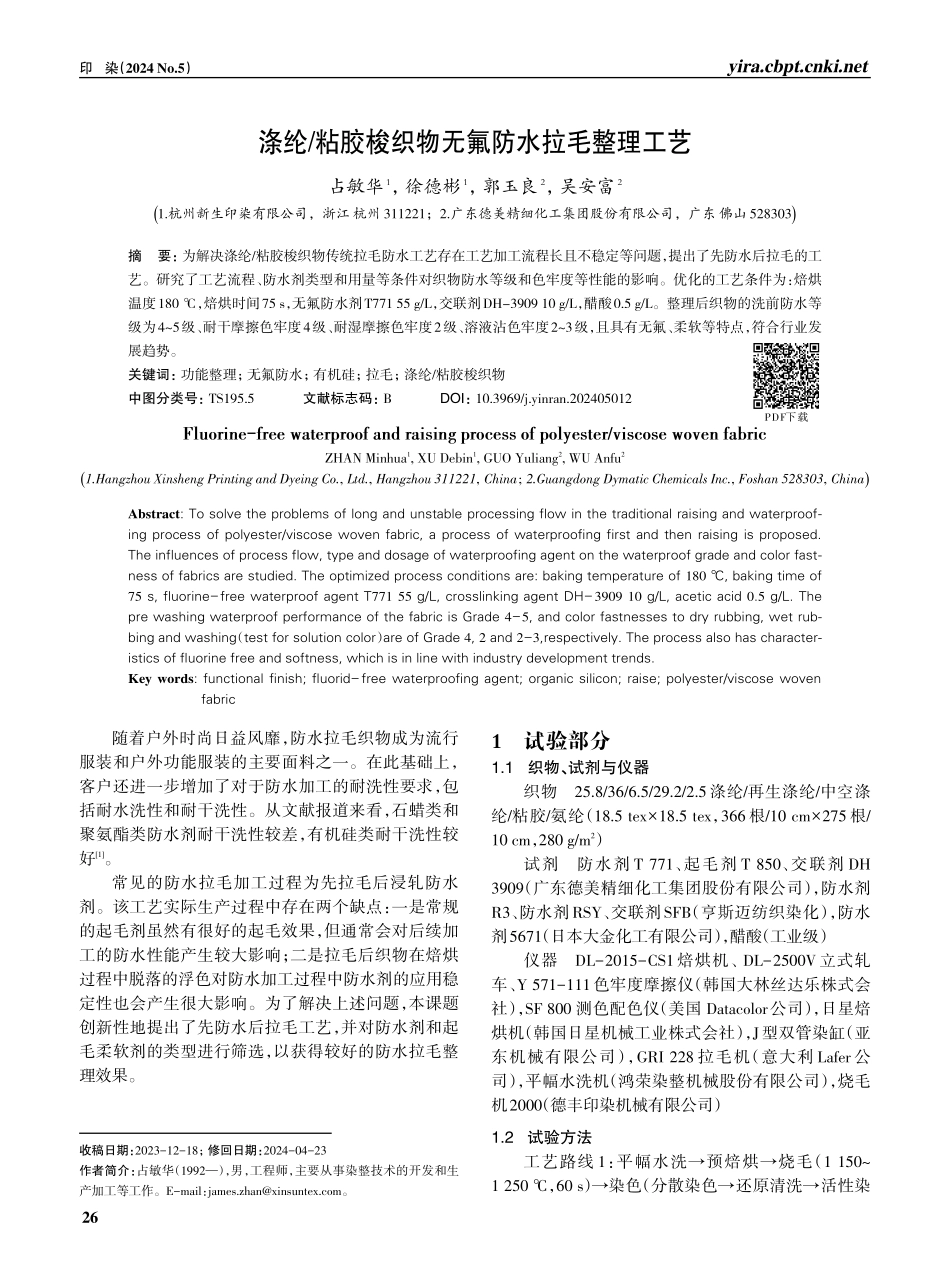

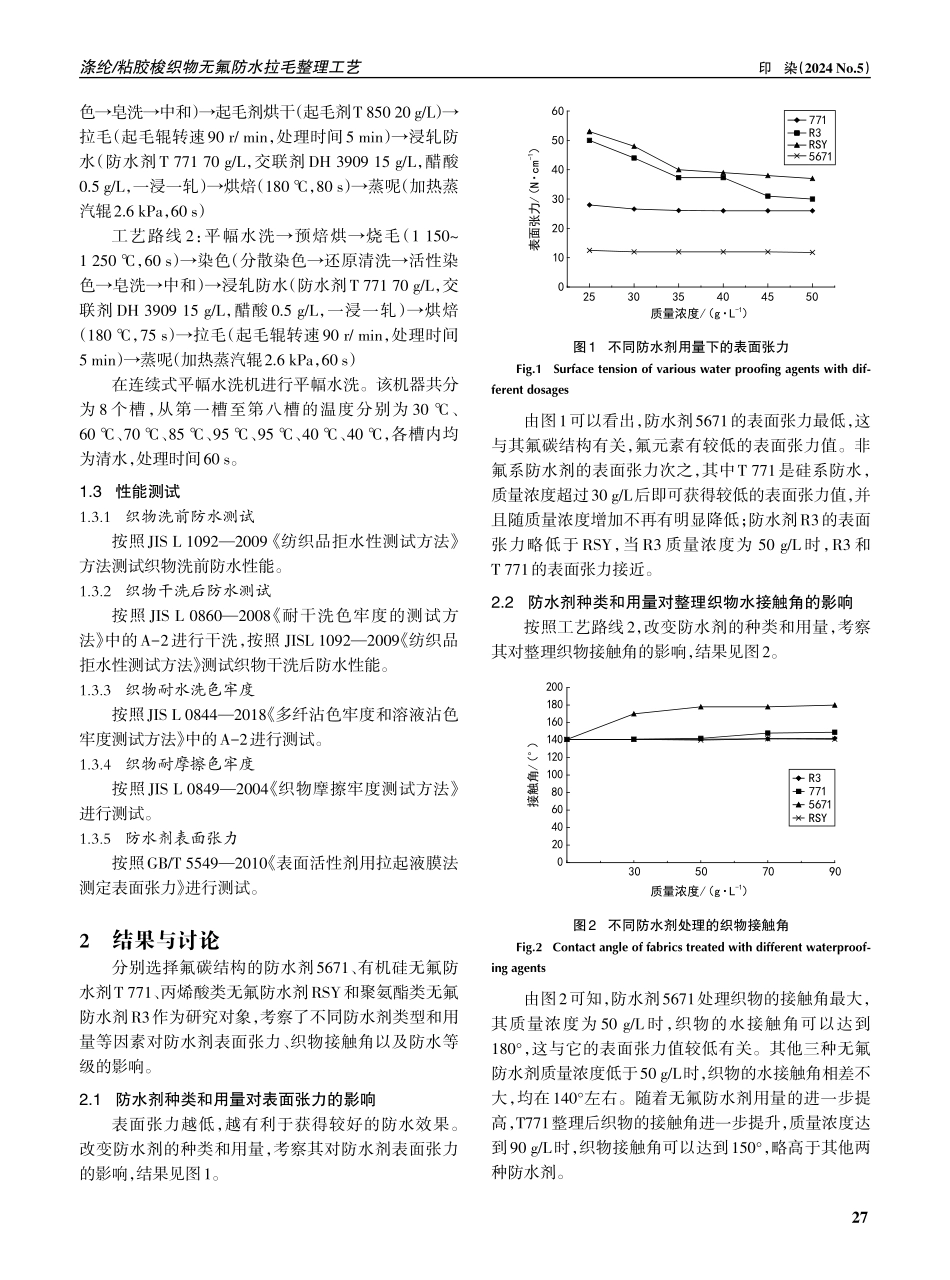

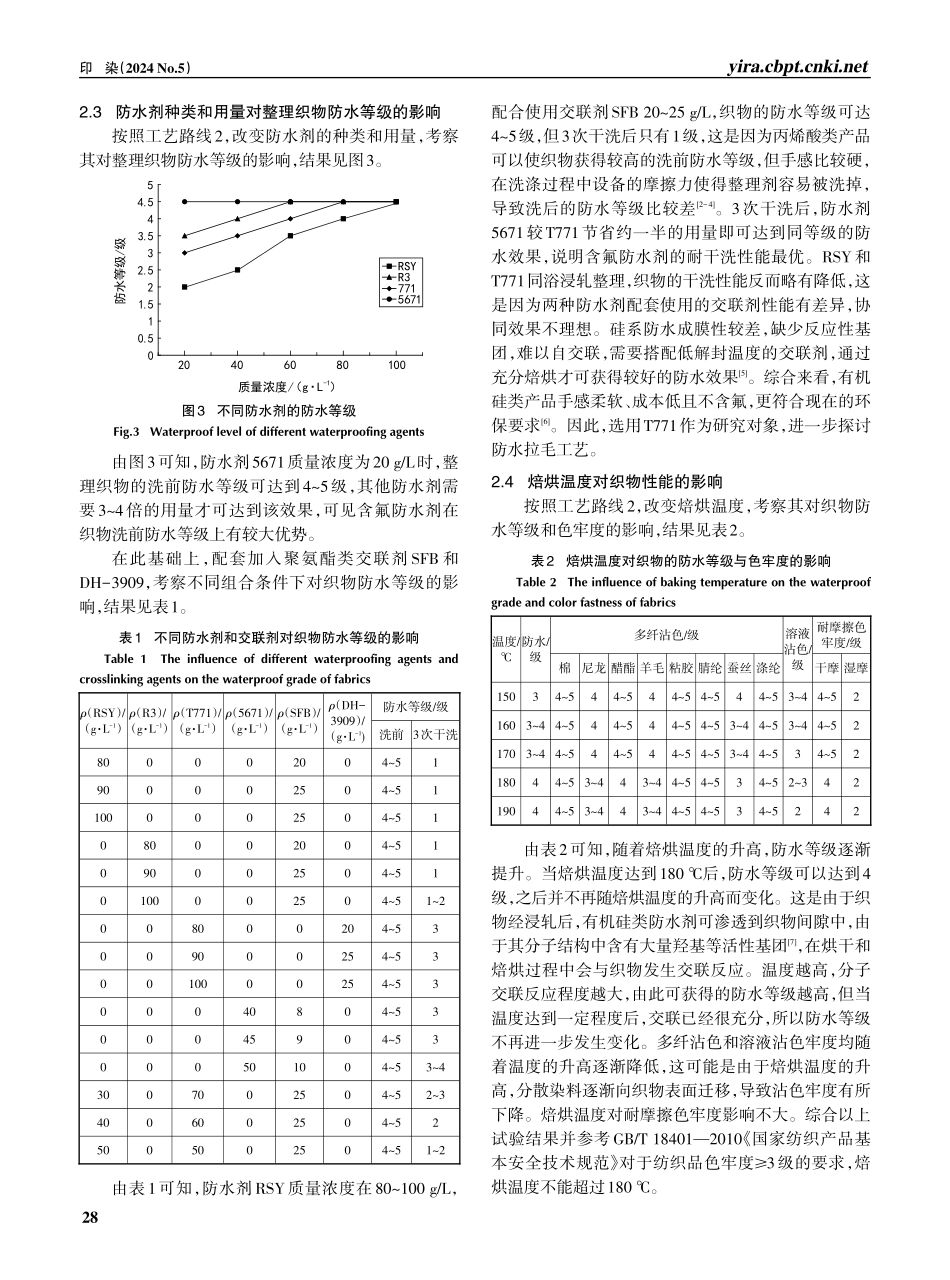

印染(2024No.5)yira.cbpt.cnki.net涤纶/粘胶梭织物无氟防水拉毛整理工艺占敏华1,徐德彬1,郭玉良2,吴安富2()1.杭州新生印染有限公司,浙江杭州311221;2.广东德美精细化工集团股份有限公司,广东佛山528303摘要:为解决涤纶/粘胶梭织物传统拉毛防水工艺存在工艺加工流程长且不稳定等问题,提出了先防水后拉毛的工艺。研究了工艺流程、防水剂类型和用量等条件对织物防水等级和色牢度等性能的影响。优化的工艺条件为:焙烘温度180℃,焙烘时间75s,无氟防水剂T77155g/L,交联剂DH-390910g/L,醋酸0.5g/L。整理后织物的洗前防水等级为4~5级、耐干摩擦色牢度4级、耐湿摩擦色牢度2级、溶液沾色牢度2~3级,且具有无氟、柔软等特点,符合行业发展趋势。关键词:功能整理;无氟防水;有机硅;拉毛;涤纶/粘胶梭织物中图分类号:TS195.5文献标志码:BDOI:10.3969/j.yinran.202405012Fluorine-freewaterproofandraisingprocessofpolyester/viscosewovenfabricZHANMinhua1,XUDebin1,GUOYuliang2,WUAnfu2()1.HangzhouXinshengPrintingandDyeingCo.,Ltd.,Hangzhou311221,China;2.GuangdongDymaticChemicalsInc.,Foshan528303,ChinaAbstract:Tosolvetheproblemsoflongandunstableprocessingflowinthetraditionalraisingandwaterproof⁃ingprocessofpolyester/viscosewovenfabric,aprocessofwaterproofingfirstandthenraisingisproposed.Theinfluencesofprocessflow,typeanddosageofwaterproofingagentonthewaterproofgradeandcolorfast⁃nessoffabricsarestudied.Theoptimizedprocessconditionsare:bakingtemperatureof180℃,bakingtimeof75s,fluorine-freewaterproofagentT77155g/L,crosslinkingagentDH-390910g/L,aceticacid0.5g/L.TheprewashingwaterproofperformanceofthefabricisGrade4-5,andcolorfastnessestodryrubbing,wetrub⁃bingandwashing(testforsolutioncolor)areofGrade4,2and2-3,respectively.Theprocessalsohascharacter⁃isticsoffluorinefreeandsoftness,whichisinlinewithindustrydevelopmenttrends.Keywords:functionalfinish;fluorid-freewaterproofingagent;organicsilicon;raise;polyester/viscosewovenfabric随着户外时尚日益风靡,防水拉毛织物成为流行服装和户外功能服装的主要面料之一。在此基础上,客户还进一步增加了对于防水加工的耐洗性要求,包括耐水洗性和耐干洗性。从文献报道来看,石蜡类和聚氨酯类防水剂耐干洗性较...