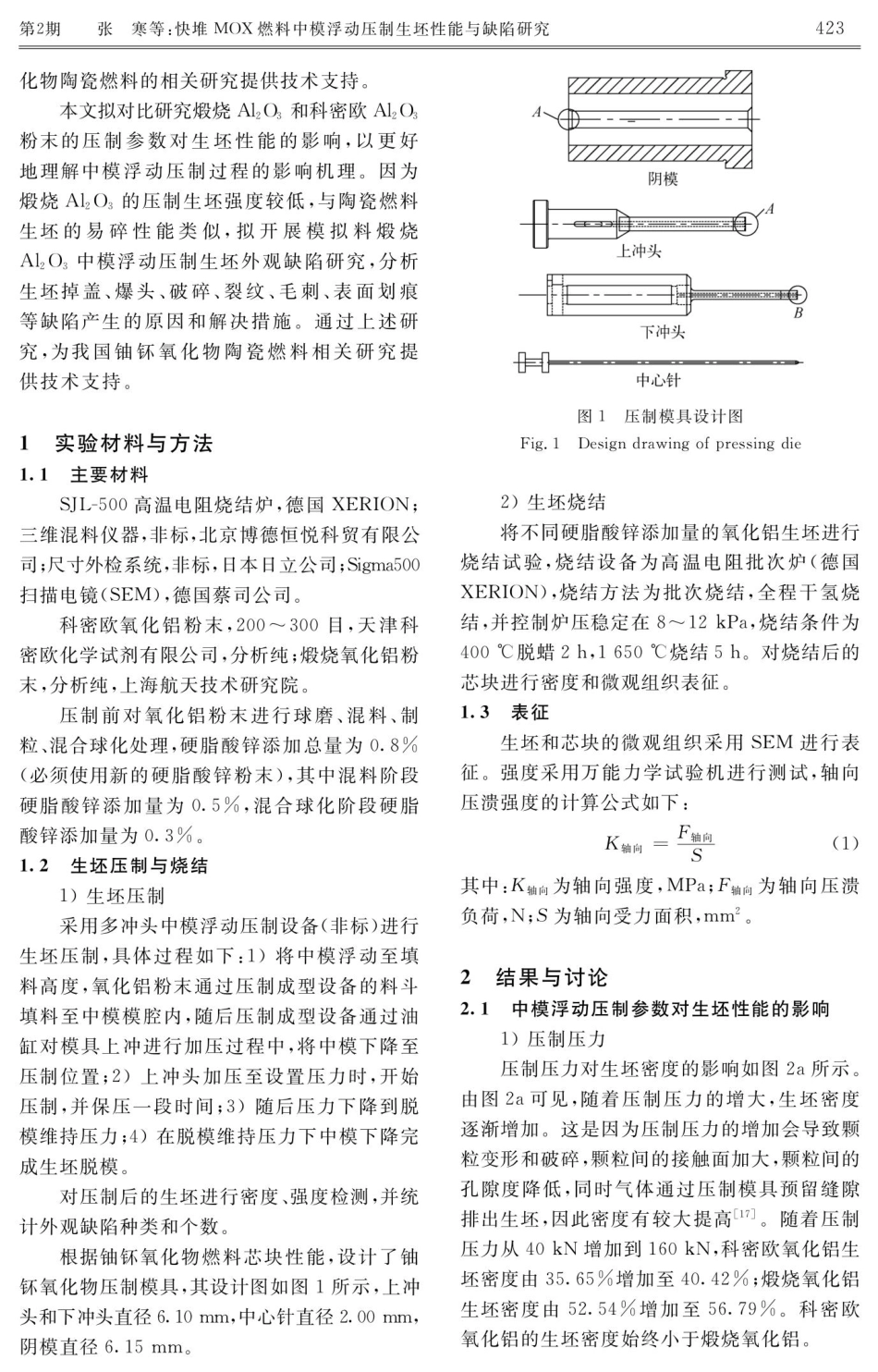

第58卷第2期2024年2月原子能科学技术AtomicEnergyScienceandTechnologyVol.58,No.2Feb.2024快堆MOX燃料中模浮动压制生坏性能与缺陷研究张寒,王军平,朱桐宇,张顺孝,潘传龙,艾利君(中核四0四有限公司,甘肃兰州732850)摘要:生坏压制成型是MOX燃料制备的关键步骤,本文采用中模浮动压制技术进行MOX燃料原料氧化铝的生坏压制和芯块烧结,对比两种氧化铝粉末的中模浮动压制性能,并研究生坏外观缺陷产生的原因和解决措施。结果表明,科密欧氧化铝生坏和熳烧氧化铝生坏的成型性和压缩性相反;随着压制压力的增加,科密欧氧化铝生坏和熳烧氧化铝生坏密度和强度逐渐增加,但压制粉末性能对生坏密度和强度的影响程度大于压制参数。生坏密度和强度与粉末性能和压制压力有关,与加压时间、降压时间和脱模维持压力无关,两种氧化铝生坏压制曲线均较好地符合黄培云双对数方程;随着压制压力的增加和脱模维持压力的减小,生坏掉盖、爆头和破碎减少;随着硬脂酸锌添加量的增加,生坏侧面划痕消失,但芯块密度逐渐降低。关键词:物料性能;密度;强度;压制压力;脱模维持压力;硬脂酸锌添加量中图分类号:TL352doi:10.7538/yzk.2023.youxian.0287ResearchofPropertyandDefectofFastReactorMOXFuelGreenPelletinFloatingPressing文献标志码:A文章编号:1000-6931(2024)02-0421-10ZHANGHan,WANGJunping,ZHUTongyu,ZHANGShunxiao,PANChuanlong,AILijun*(The404CompanyLimited,CNNC,Lanzhou732850,China)Abstract:Greenpelletpressingiscriticalstepinthepreparationofoxideceramicfuelthatdecidesdensity,strengthandmicrostructureofgreenpelletsandpellets.Themedi-ummodefloatingpressingpropertiesofcalcinedaluminaandComeoaluminapowderwerecompared,andthecausesandsolvingmeasuresofgreenpelletsappearancedefectswerestudied.TheresultsshowthatthedensityofcalcinedaluminacompactismuchhigherthanthatofComeoaluminacompact,butthestrengthofcalcinedaluminacom-pactismuchlowerthanthatofComeoaluminacompact.Theformabilityandcompressi-bilityofComeoaluminaandcalcinedaluminaareopposite.Withtheincreaseofpressingpressure,thedensityandstrengthofComeoaluminagreenpelletsandcalcinedaluminagreenpelletsgraduallyincrease,buttheinfluenceofthepropertiesofpressingpowder收稿日期:2023-04-20;修回日期:2023-06-08*通信作者:艾利君42...