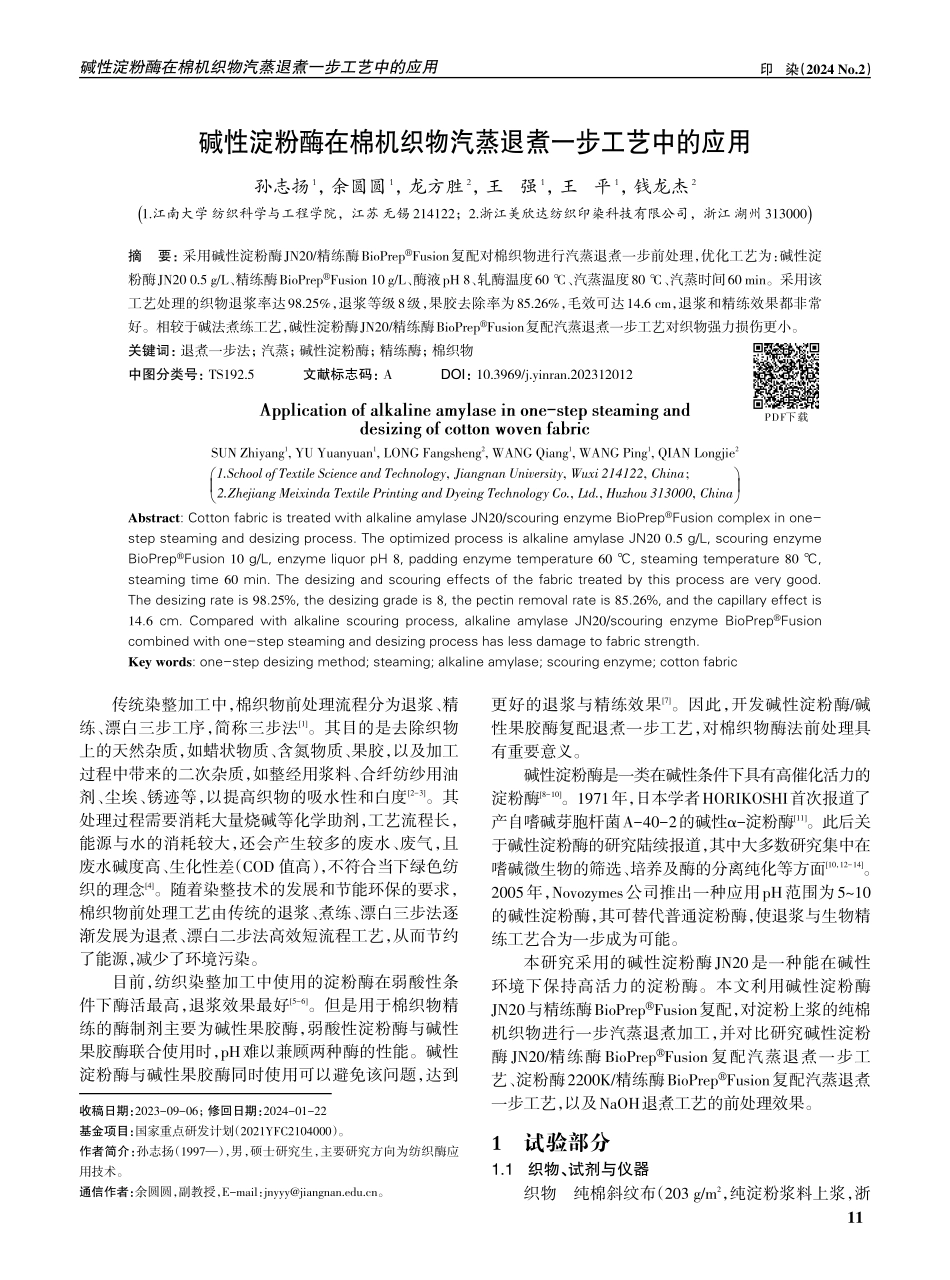

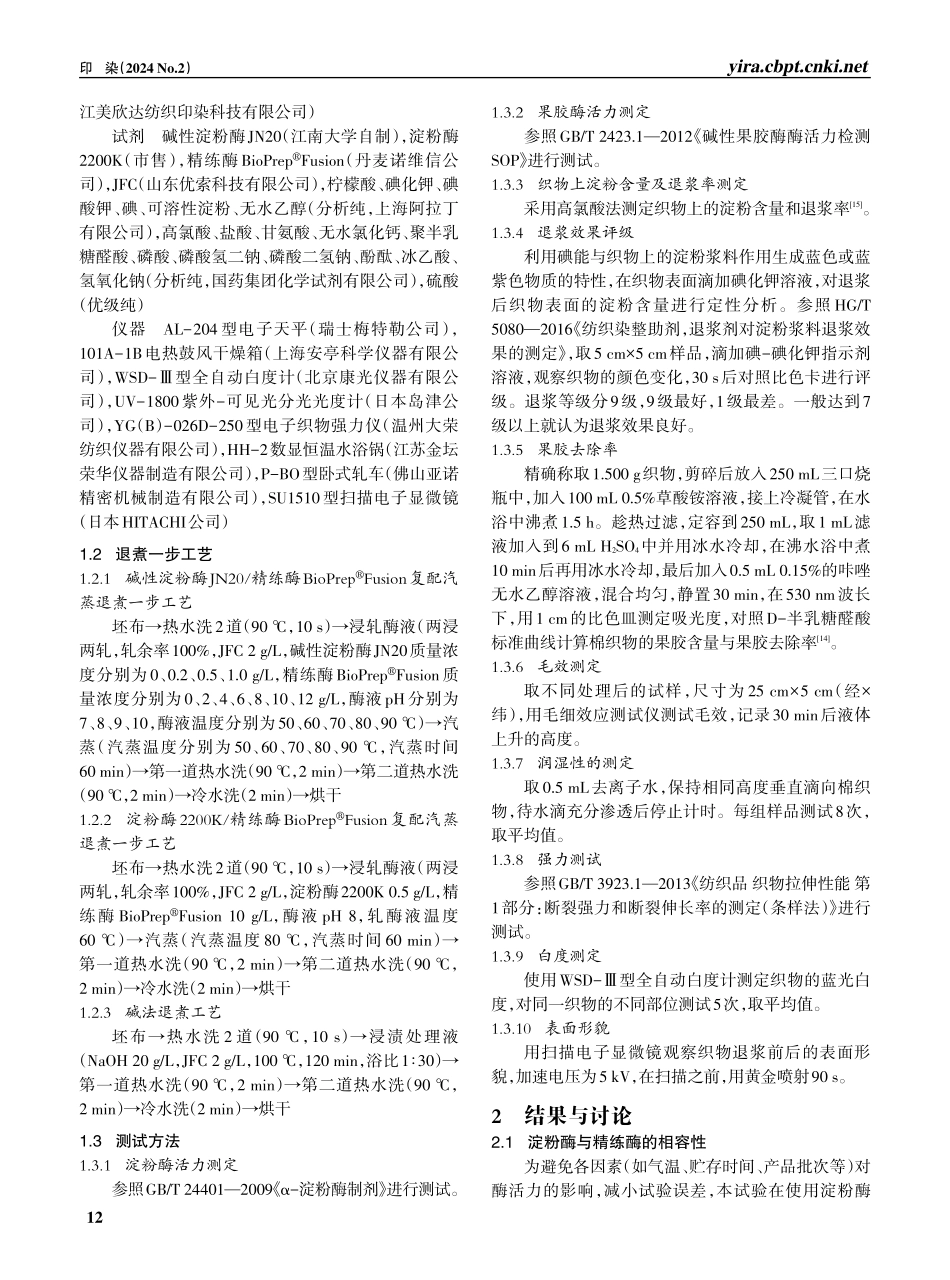

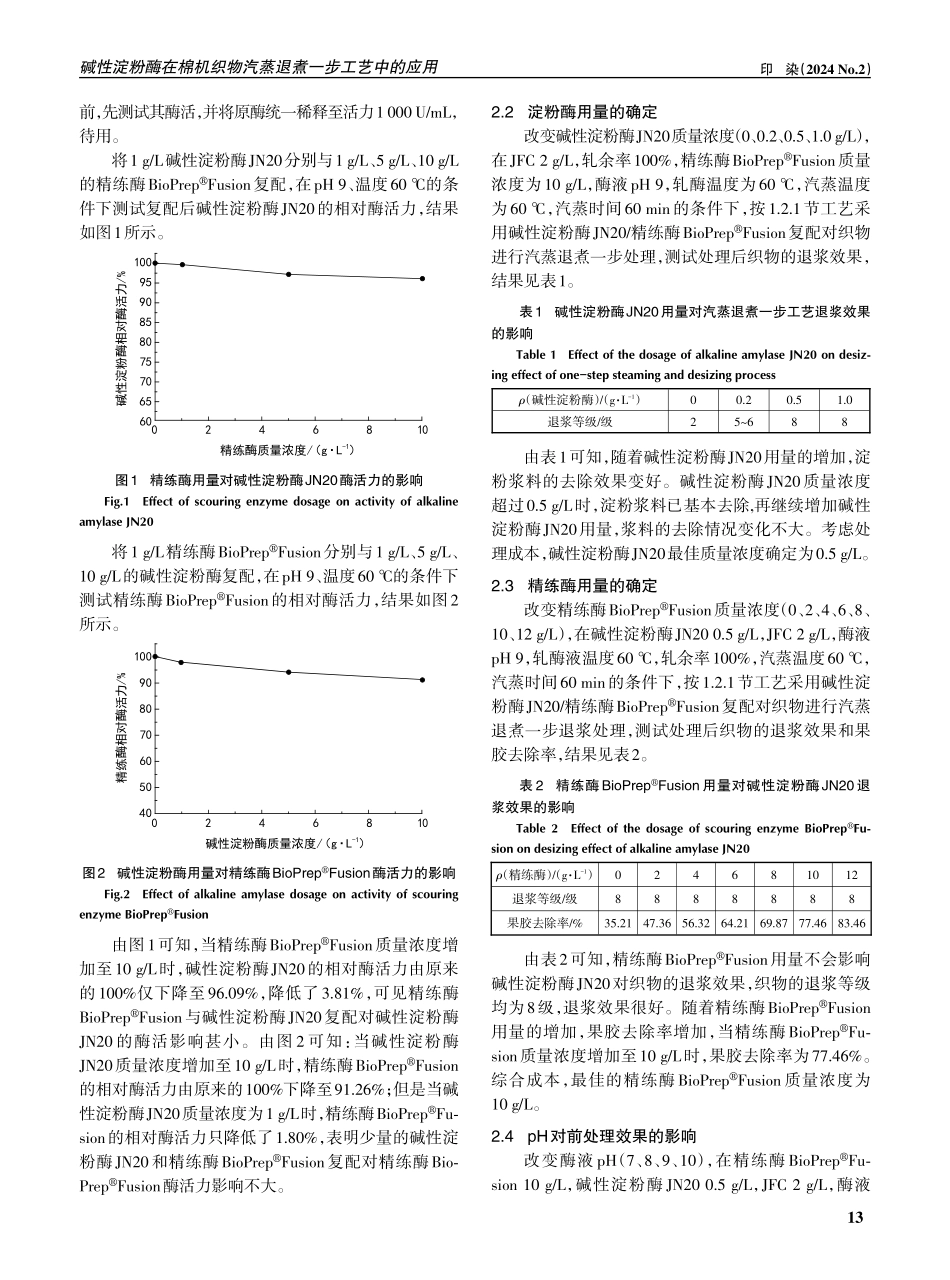

碱性淀粉酶在棉机织物汽蒸退煮一步工艺中的应用印染(2024No.2)碱性淀粉酶在棉机织物汽蒸退煮一步工艺中的应用孙志扬1,余圆圆1,龙方胜2,王强1,王平1,钱龙杰2()1.江南大学纺织科学与工程学院,江苏无锡214122;2.浙江美欣达纺织印染科技有限公司,浙江湖州313000摘要:采用碱性淀粉酶JN20/精练酶BioPrep®Fusion复配对棉织物进行汽蒸退煮一步前处理,优化工艺为:碱性淀粉酶JN200.5g/L、精练酶BioPrep®Fusion10g/L、酶液pH8、轧酶温度60℃、汽蒸温度80℃、汽蒸时间60min。采用该工艺处理的织物退浆率达98.25%,退浆等级8级,果胶去除率为85.26%,毛效可达14.6cm,退浆和精练效果都非常好。相较于碱法煮练工艺,碱性淀粉酶JN20/精练酶BioPrep®Fusion复配汽蒸退煮一步工艺对织物强力损伤更小。关键词:退煮一步法;汽蒸;碱性淀粉酶;精练酶;棉织物中图分类号:TS192.5文献标志码:ADOI:10.3969/j.yinran.202312012Applicationofalkalineamylaseinone-stepsteaminganddesizingofcottonwovenfabricSUNZhiyang1,YUYuanyuan1,LONGFangsheng2,WANGQiang1,WANGPing1,QIANLongjie2æèççöø÷÷1.SchoolofTextileScienceandTechnology,JiangnanUniversity,Wuxi214122,China;2.ZhejiangMeixindaTextilePrintingandDyeingTechnologyCo.,Ltd.,Huzhou313000,ChinaAbstract:CottonfabricistreatedwithalkalineamylaseJN20/scouringenzymeBioPrep®Fusioncomplexinone-stepsteaminganddesizingprocess.TheoptimizedprocessisalkalineamylaseJN200.5g/L,scouringenzymeBioPrep®Fusion10g/L,enzymeliquorpH8,paddingenzymetemperature60℃,steamingtemperature80℃,steamingtime60min.Thedesizingandscouringeffectsofthefabrictreatedbythisprocessareverygood.Thedesizingrateis98.25%,thedesizinggradeis8,thepectinremovalrateis85.26%,andthecapillaryeffectis14.6cm.Comparedwithalkalinescouringprocess,alkalineamylaseJN20/scouringenzymeBioPrep®Fusioncombinedwithone-stepsteaminganddesizingprocesshaslessdamagetofabricstrength.Keywords:one-stepdesizingmethod;steaming;alkalineamylase;scouringenzyme;cottonfabric传统染整加工中,棉织物前处理流程分为退浆、精练、漂白三步工序,简称三步法[1]。其目的是去除织物上的天然杂质,如蜡状物质、含氮物质、果胶,以及加工过程中带来的二次杂质,如整经用浆料、合纤纺纱用油剂、尘埃...