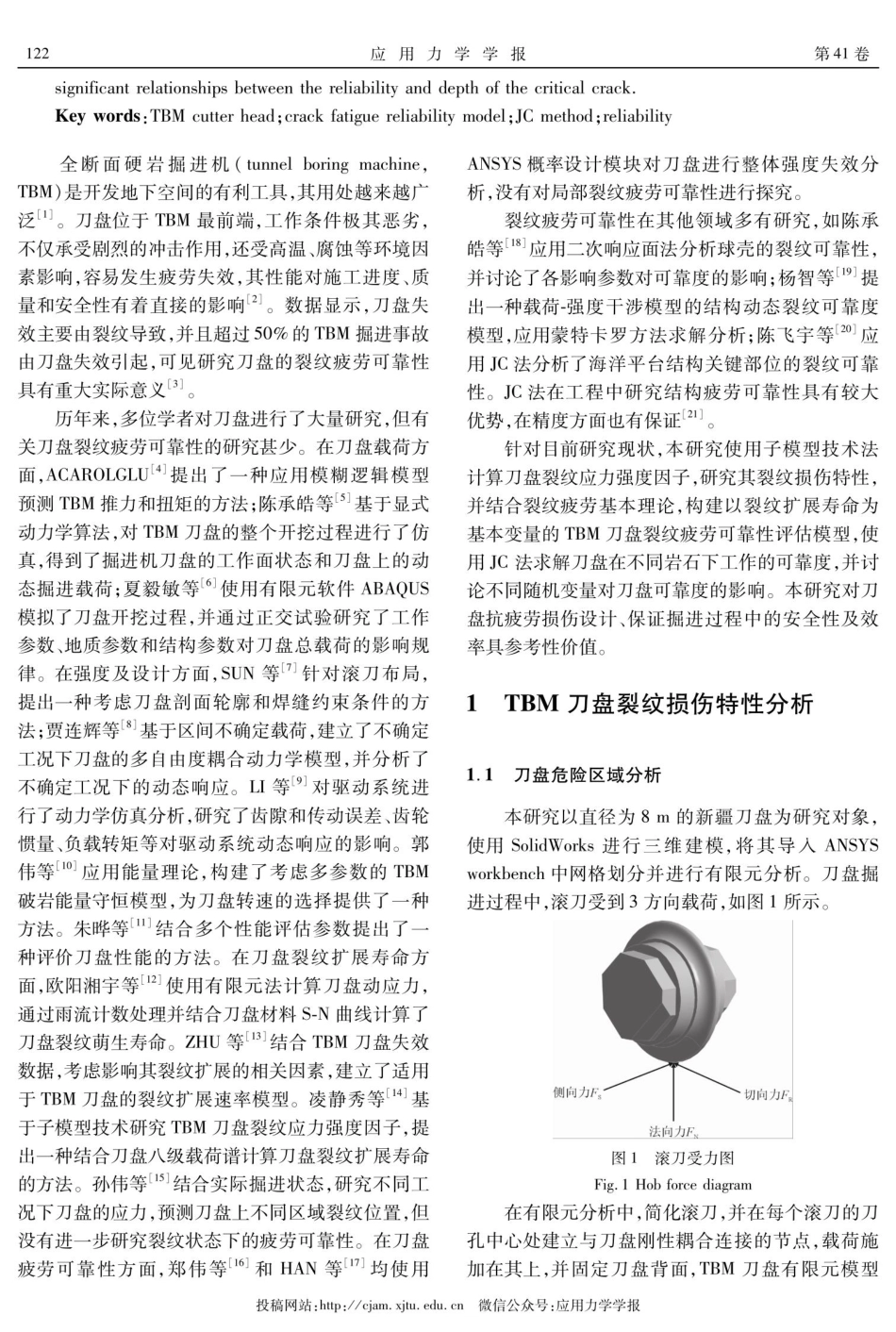

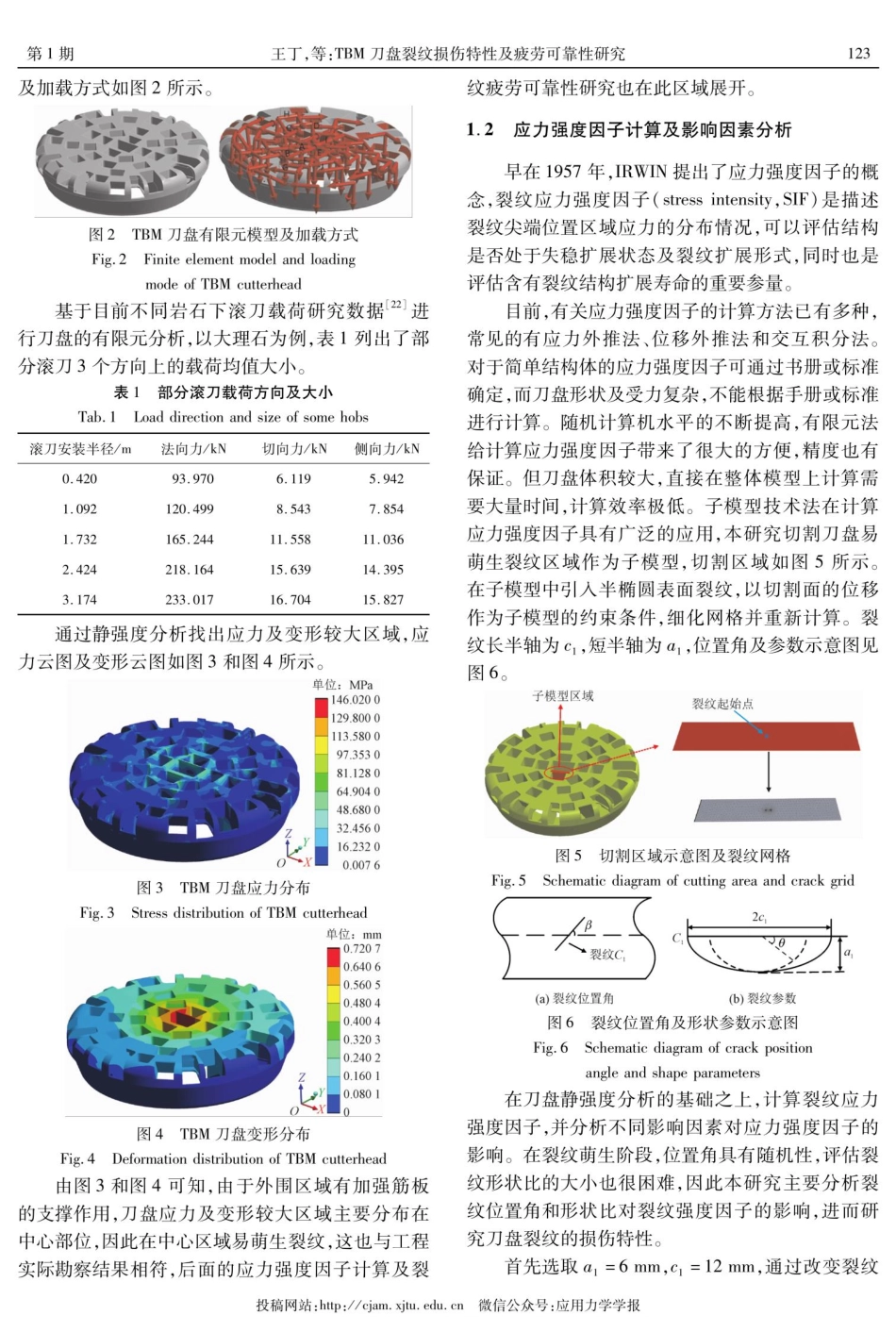

第41卷第1期2024年2月文章编号:1000-4939(2024)01-0121-08应用力学学报ChineseJournalofAppliedMechanicsVol.41No.1Feb.2024TBM刀盘裂纹损伤特性及疲劳可靠性研究王丁1,2,曲传咏1,2(1.天津大学力学系,300072天津;2.天津市现代工程力学重点实验室,300072天津)摘要:刀盘作为硬岩掘进机(tunnelboringmachine,TBM)工作过程中的核心受力载体,承受多方向的随机载荷,容易萌生裂纹导致疲劳失效,影响施工进度和安全,因此研究其裂纹疲劳可靠性具有重要意义。本研究通过受力分析得到刀盘易萌生裂纹区域及应力特征,并使用子模型技术法计算刀盘裂纹应力强度因子,研究刀盘裂纹损伤特性;然后结合裂纹疲劳理论,构建了以裂纹扩展寿命为基本变量的TBM刀盘裂纹疲劳可靠性评估模型,应用JC法求解刀盘在不同工作环境下的可靠度,并讨论了不同因素对刀盘可靠度的影响。研究表明:裂纹尖端最深处的裂纹扩展以张开型和撕开型为主,而裂纹两端3种扩展形式都存在;刀盘的裂纹疲劳可靠度随着初始裂纹深度的增大而显著减小,随着裂纹形状比的增大而增大,而临界裂纹深度的变化对可靠度的影响不明显。关键词:TBM刀盘;裂纹疲劳可靠性模型;JC法;可靠度中图分类号:0346.2;0348.3ResearchonTBMcutterheadcrackdamageandfatiguereliability2.TianjinKeyLaboratoryofModernEngineeringMechanics,300072Tianjin,China)Abstract:Cutterheadofatunnelboringmachine(TBM),themainweightedpartintheprocessoftunneling,bearsloadingsindifferentdirections.Afatiguefailureofcutterheadwouldseverelyaffecttheconstructionprogressandsafety.Therefore,itisofgreatimportancetostudythefatiguereliabilityofitscracks.Inthispaper,thecriticalpointofthecutterheadwasfoundusingthestaticstrengthanalysis,andweanalyzedthedynamicstresscharacteristics.Inaddition,thestressintensityfactorofcutterheadcrackwascalculatedusingthesubmodeltechnique,andthecrackpropagationmechanismanddamagecharacteristicsofcutterheadcrackwerealsoanalyzed.Then,combinedwithcrackfatiguetheory,weproposedafatiguereliabilityevaluationmethodbasedonJCmethod,andtheeffectsofdifferentfactorsonthereliabilitywerediscussedfordifferentgeologicalconditions.Theresultsshowthatthecrackpropagationhasopen-typeandtear-typeinthedeepestpartofthecracktip,buttherearethreekin...