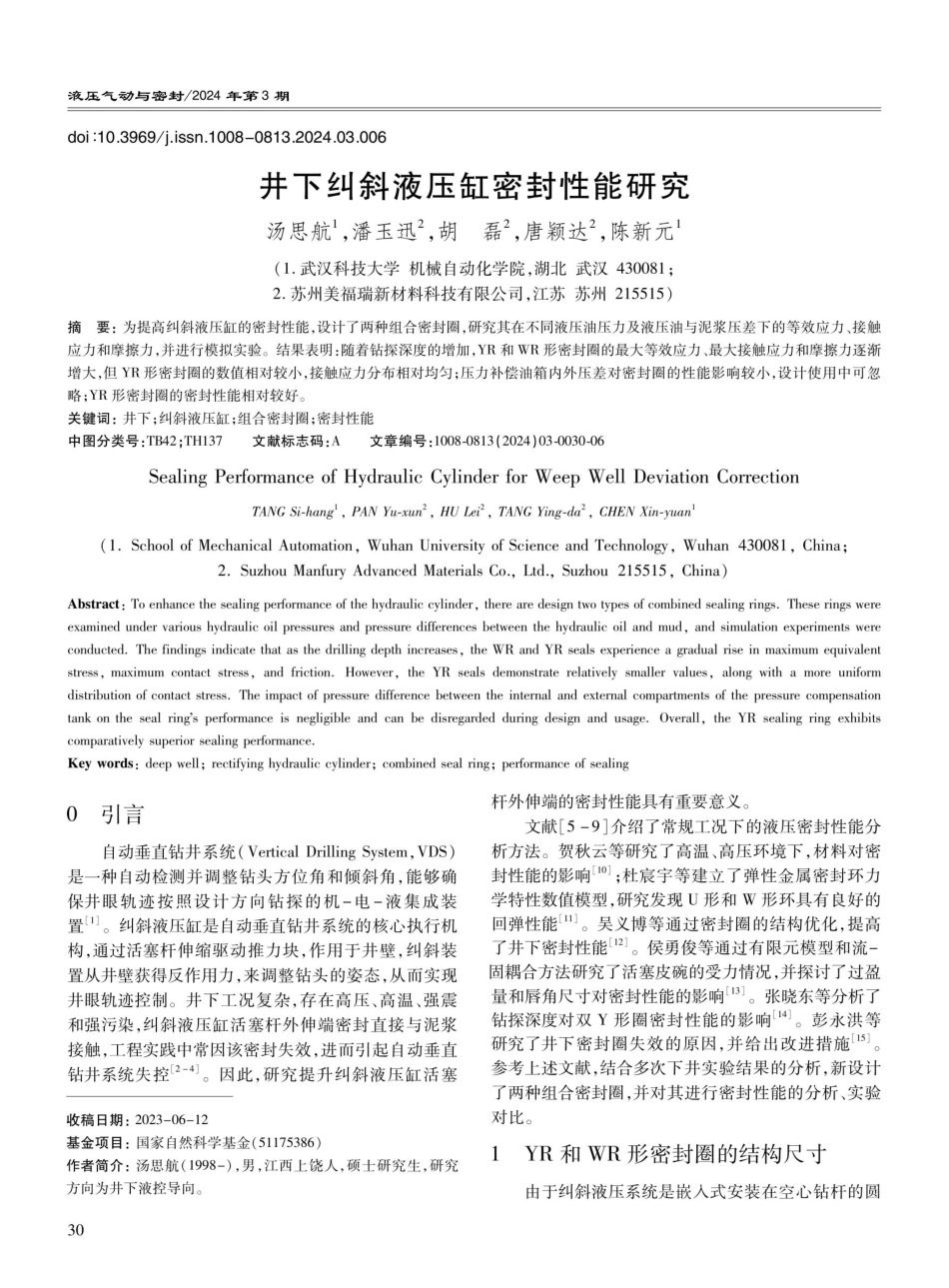

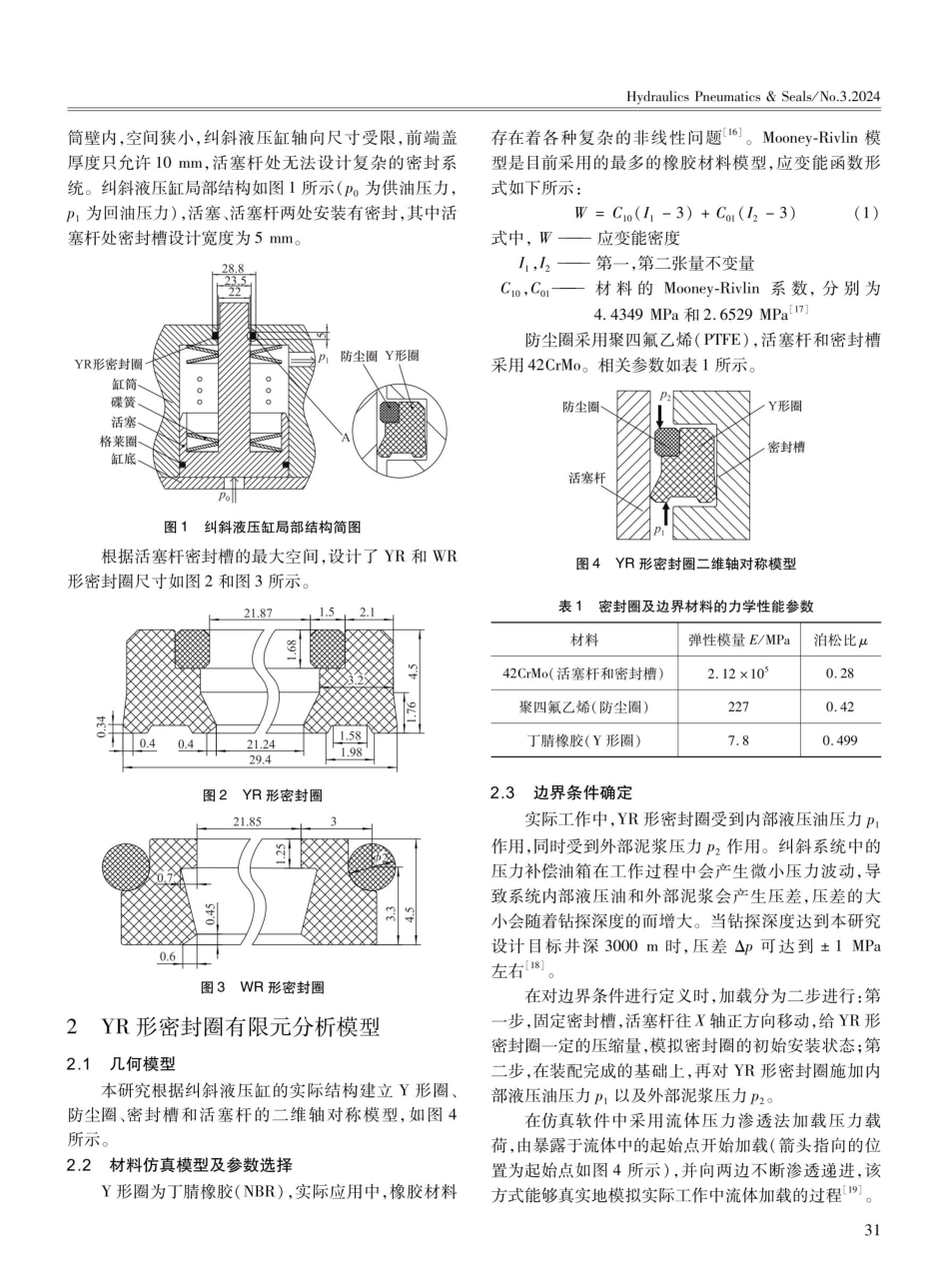

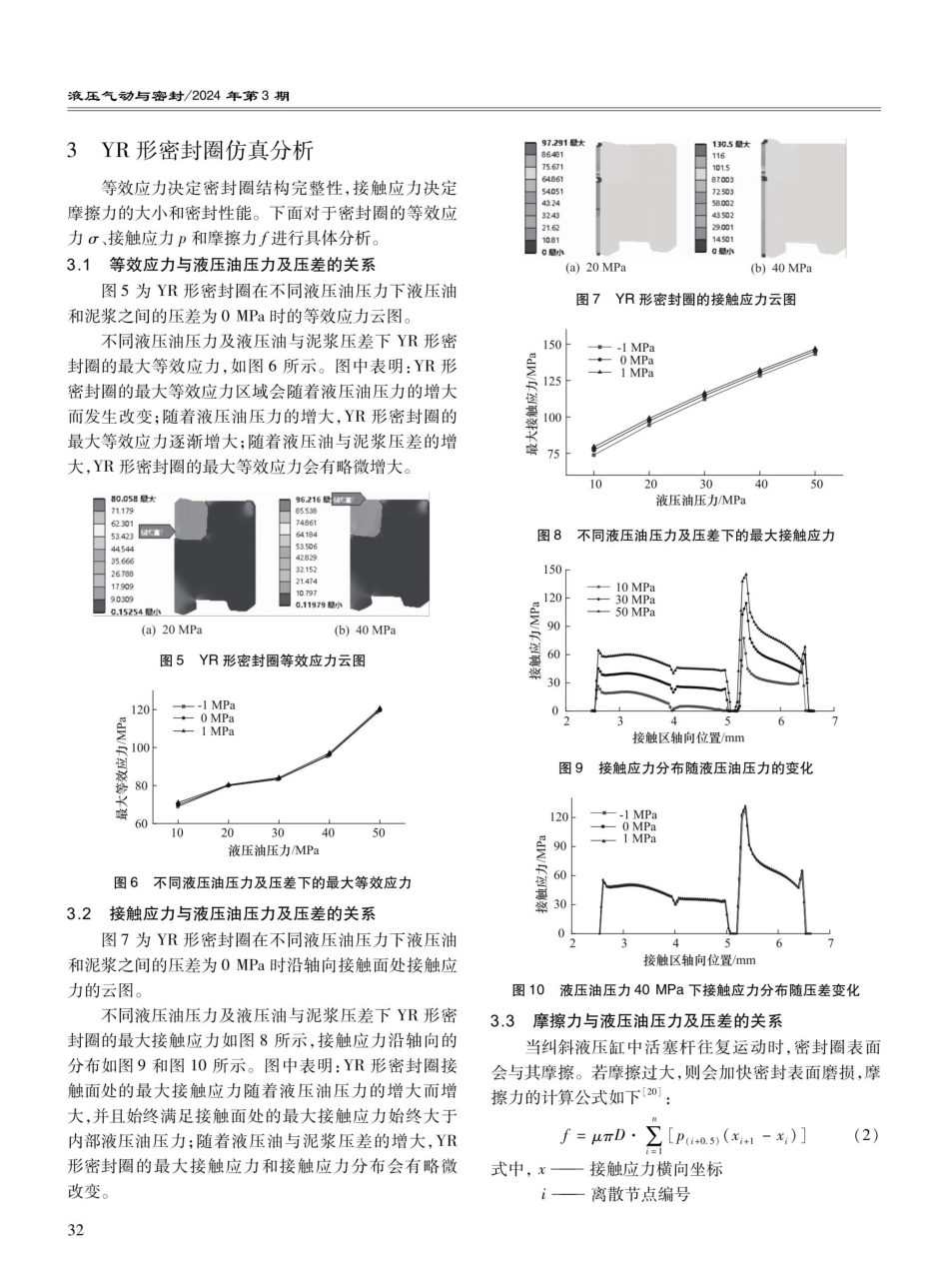

井下纠斜液压缸密封性能研究液压气动与密封/2024年第3期doi:10.3969/j.issn.1008-0813.2024.03.006摘要:为提高纠斜液压缸的密封性能,设计了两种组合密封圈,研究其在不同液压油压力及液压油与泥浆压差下的等效应力、接触应力和摩擦力,并进行模拟实验。结果表明:随着钻探深度的增加,YR和WR形密封圈的最大等效应力、最大接触应力和摩擦力逐渐增大,但YR形密封圈的数值相对较小,接触应力分布相对均匀;压力补偿油箱内外压差对密封圈的性能影响较小,设计使用中可忽略;YR形密封圈的密封性能相对较好。关键词:井下;纠斜液压缸;组合密封圈;密封性能中图分类号:TB42;TH137SealingPerformanceofHydraulicCylinderforWeepWellDeviationCorrection(1.SchoolofMechanicalAutomation,WuhanUniversityofScienceandTechnology,Wuhan430081,China;2.SuzhouManfuryAdvancedMaterialsCo.,Ltd.,Suzhou215515,China)Abstract:Toenhancethesealingperformanceofthehydrauliccylinder,therearedesigntwotypesofcombinedsealingrings.Theseringswereexaminedundervarioushydraulicoilpressuresandpressuredifferencesbetweenthehydraulicoilandmud,andsimulationexperimentswereconducted.Thefindingsindicatethatasthedrillingdepthincreases,theWRandYRsealsexperienceagradualriseinmaximumequivalentstress,maximumcontactstress,andfriction.However,theYRsealsdemonstraterelativelysmallervalues,alongwithamoreuniformdistributionofcontactstress.Theimpactofpressuredifferencebetweentheinternalandexternalcompartmentsofthepressurecompensationtankonthesealring'sperformanceisnegligibleandcanbedisregardedduringdesignandusage.Overall,theYRsealingringexhibitscomparativelysuperiorsealingperformance.Keywords:deepwell;rectifyinghydrauliccylinder;combinedsealring;performanceofsealing0引言自动垂直钻井系统(VerticalDrillingSystem,VDS)是一种自动检测并调整钻头方位角和倾斜角,能够确保井眼轨迹按照设计方向钻探的机-电-液集成装置"。纠斜液压缸是自动垂直钻井系统的核心执行机构,通过活塞杆伸缩驱动推力块,作用于井壁,纠斜装置从井壁获得反作用力,来调整钻头的姿态,从而实现井眼轨迹控制。井下工况复杂,存在高压、高温、强震和强污染,纠斜液压缸活塞杆外伸端密封直接与泥浆接触,工程实践中常因该密封失效,进而引起自动垂...