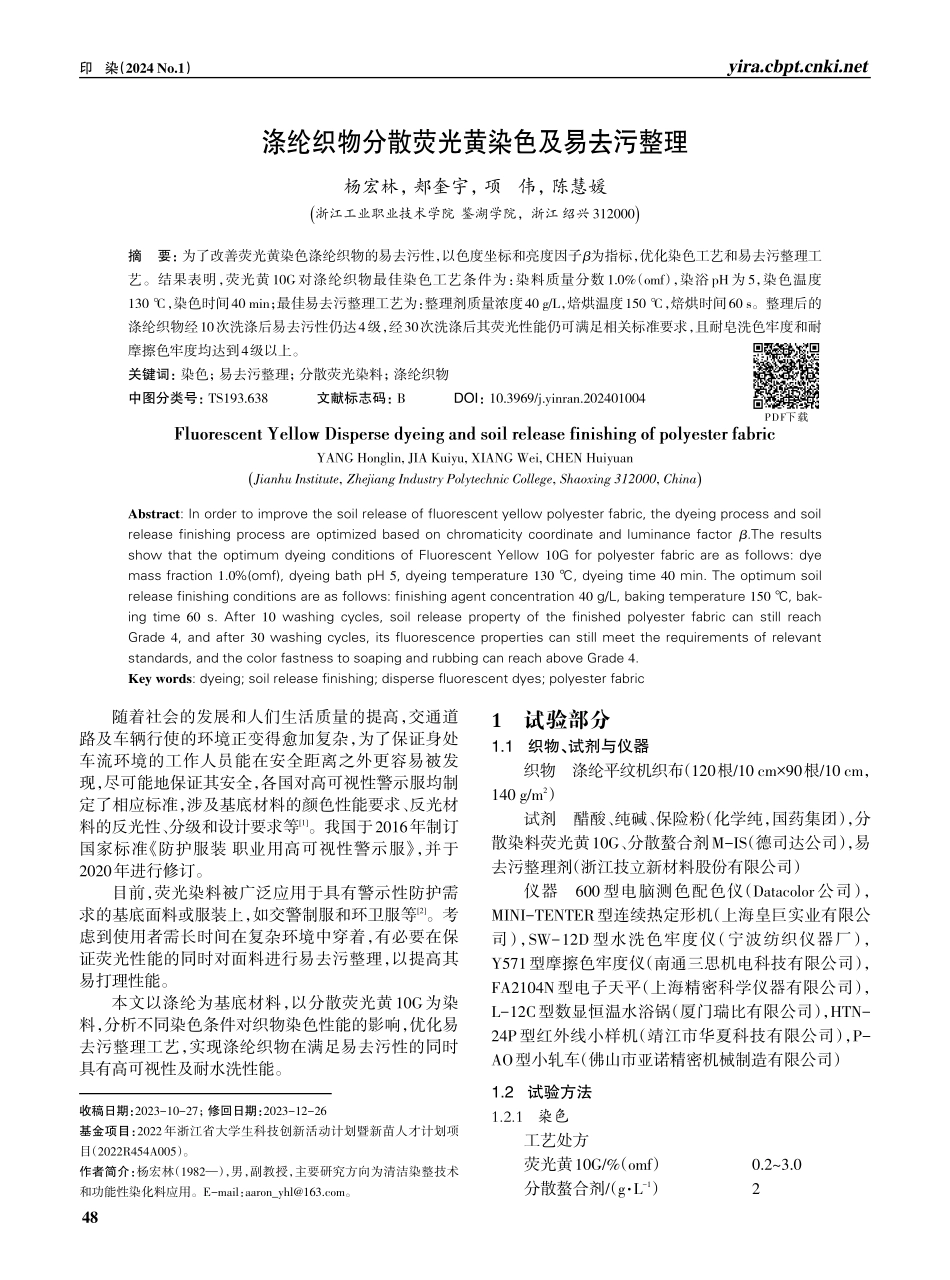

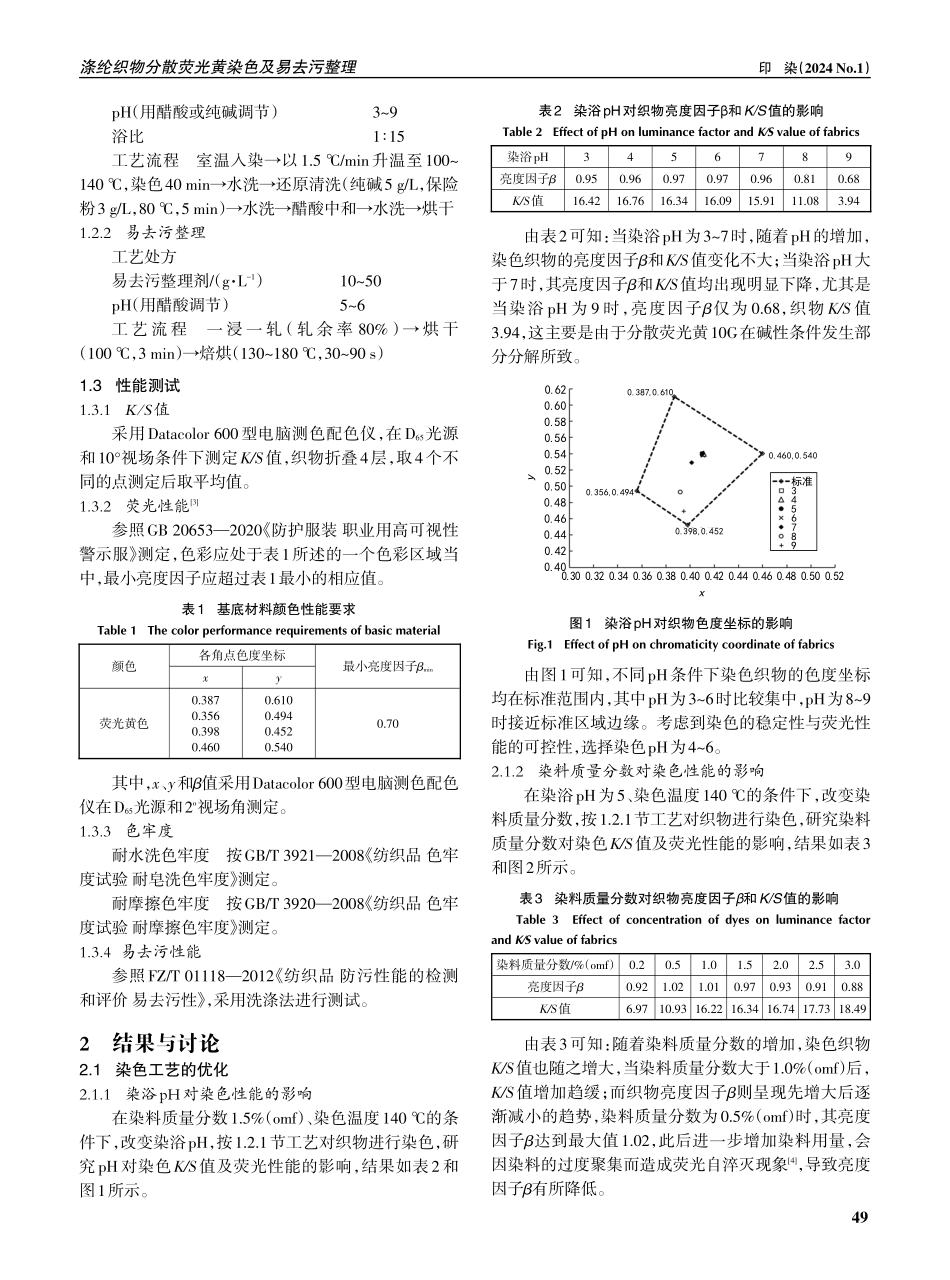

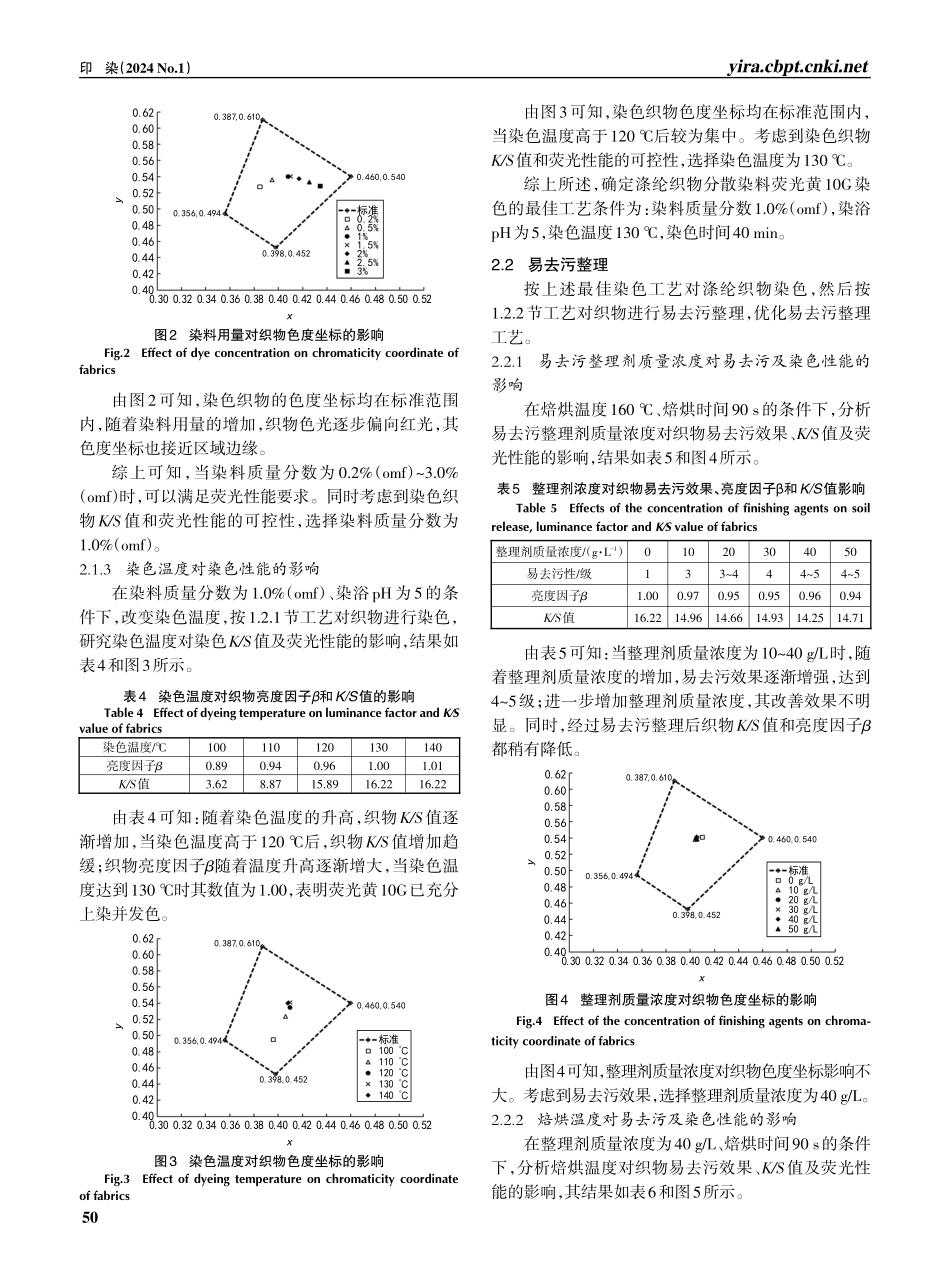

印染(2024No.1)yira.cbpt.cnki.net涤纶织物分散荧光黄染色及易去污整理杨宏林,郏奎宇,项伟,陈慧媛()浙江工业职业技术学院鉴湖学院,浙江绍兴312000摘要:为了改善荧光黄染色涤纶织物的易去污性,以色度坐标和亮度因子β为指标,优化染色工艺和易去污整理工艺。结果表明,荧光黄10G对涤纶织物最佳染色工艺条件为:染料质量分数1.0%(omf),染浴pH为5,染色温度130℃,染色时间40min;最佳易去污整理工艺为:整理剂质量浓度40g/L,焙烘温度150℃,焙烘时间60s。整理后的涤纶织物经10次洗涤后易去污性仍达4级,经30次洗涤后其荧光性能仍可满足相关标准要求,且耐皂洗色牢度和耐摩擦色牢度均达到4级以上。关键词:染色;易去污整理;分散荧光染料;涤纶织物中图分类号:TS193.638文献标志码:BDOI:10.3969/j.yinran.202401004FluorescentYellowDispersedyeingandsoilreleasefinishingofpolyesterfabricYANGHonglin,JIAKuiyu,XIANGWei,CHENHuiyuan()JianhuInstitute,ZhejiangIndustryPolytechnicCollege,Shaoxing312000,ChinaAbstract:Inordertoimprovethesoilreleaseoffluorescentyellowpolyesterfabric,thedyeingprocessandsoilreleasefinishingprocessareoptimizedbasedonchromaticitycoordinateandluminancefactorβ.TheresultsshowthattheoptimumdyeingconditionsofFluorescentYellow10Gforpolyesterfabricareasfollows:dyemassfraction1.0%(omf),dyeingbathpH5,dyeingtemperature130℃,dyeingtime40min.Theoptimumsoilreleasefinishingconditionsareasfollows:finishingagentconcentration40g/L,bakingtemperature150℃,bak⁃ingtime60s.After10washingcycles,soilreleasepropertyofthefinishedpolyesterfabriccanstillreachGrade4,andafter30washingcycles,itsfluorescencepropertiescanstillmeettherequirementsofrelevantstandards,andthecolorfastnesstosoapingandrubbingcanreachaboveGrade4.Keywords:dyeing;soilreleasefinishing;dispersefluorescentdyes;polyesterfabric随着社会的发展和人们生活质量的提高,交通道路及车辆行使的环境正变得愈加复杂,为了保证身处车流环境的工作人员能在安全距离之外更容易被发现,尽可能地保证其安全,各国对高可视性警示服均制定了相应标准,涉及基底材料的颜色性能要求、反光材料的反光性、分级和设计要求等[1]。我国于2016年制订国家标准《防护服装职业用高可视性警示服》,并于2020年进行修...