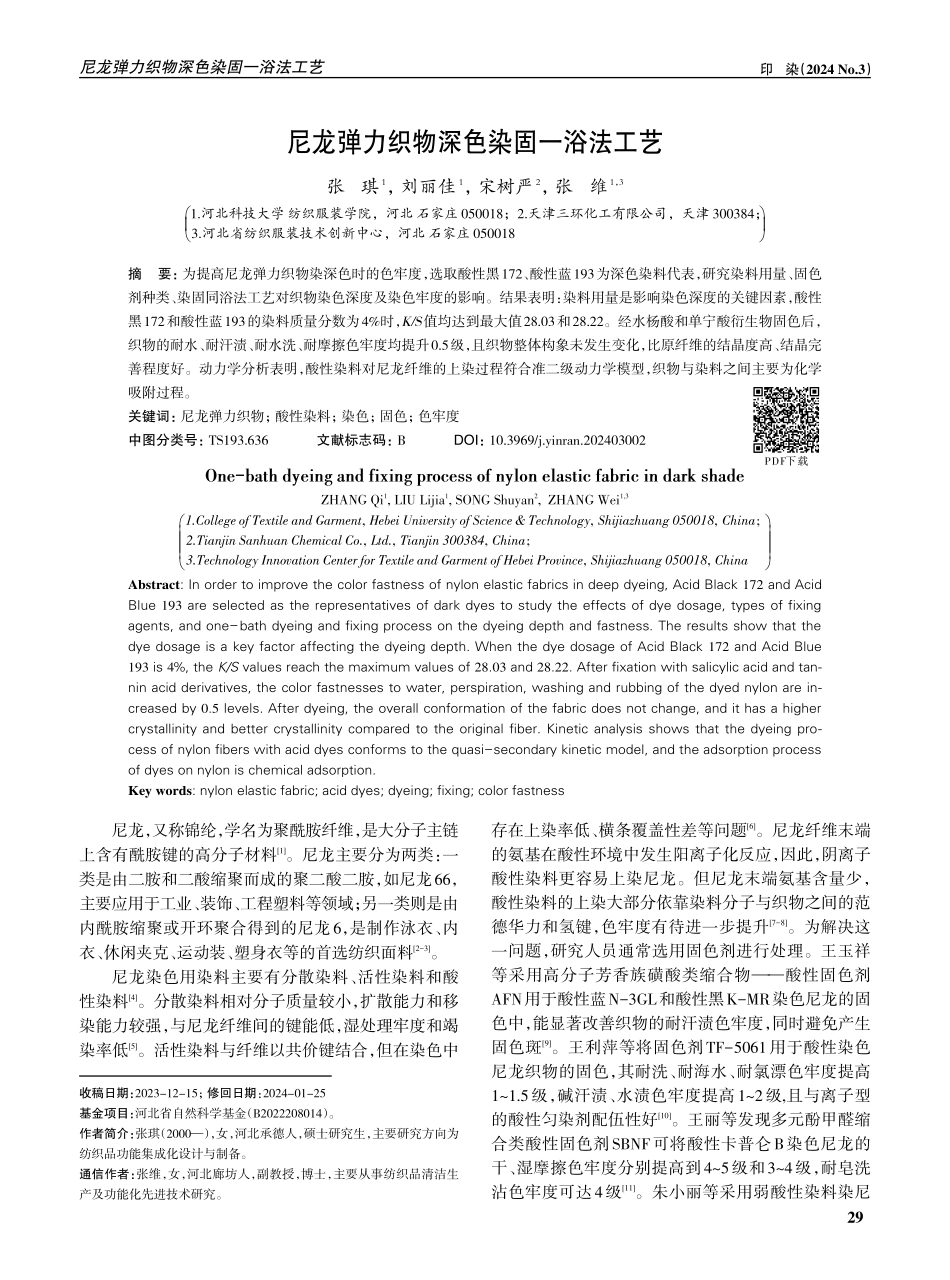

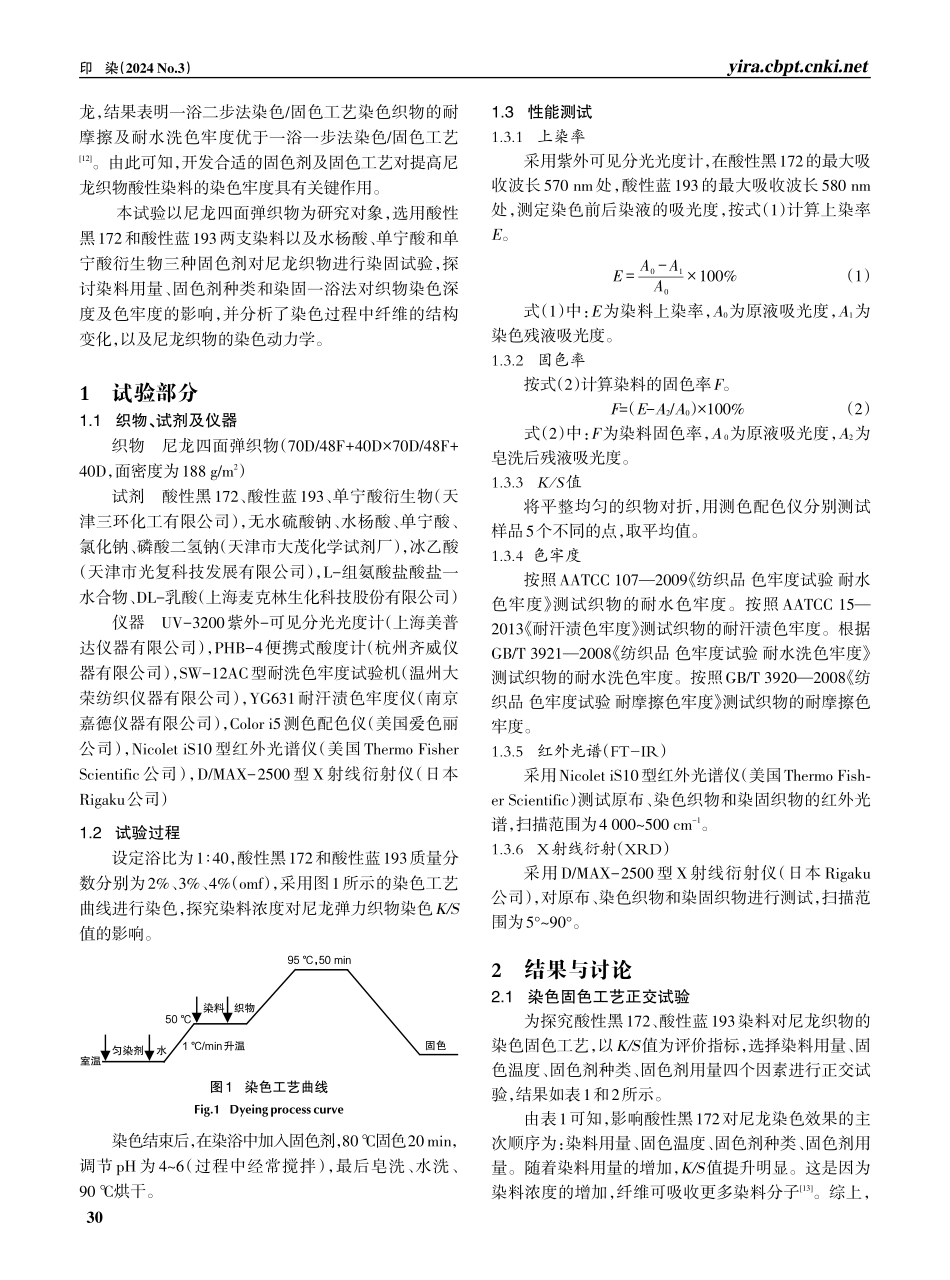

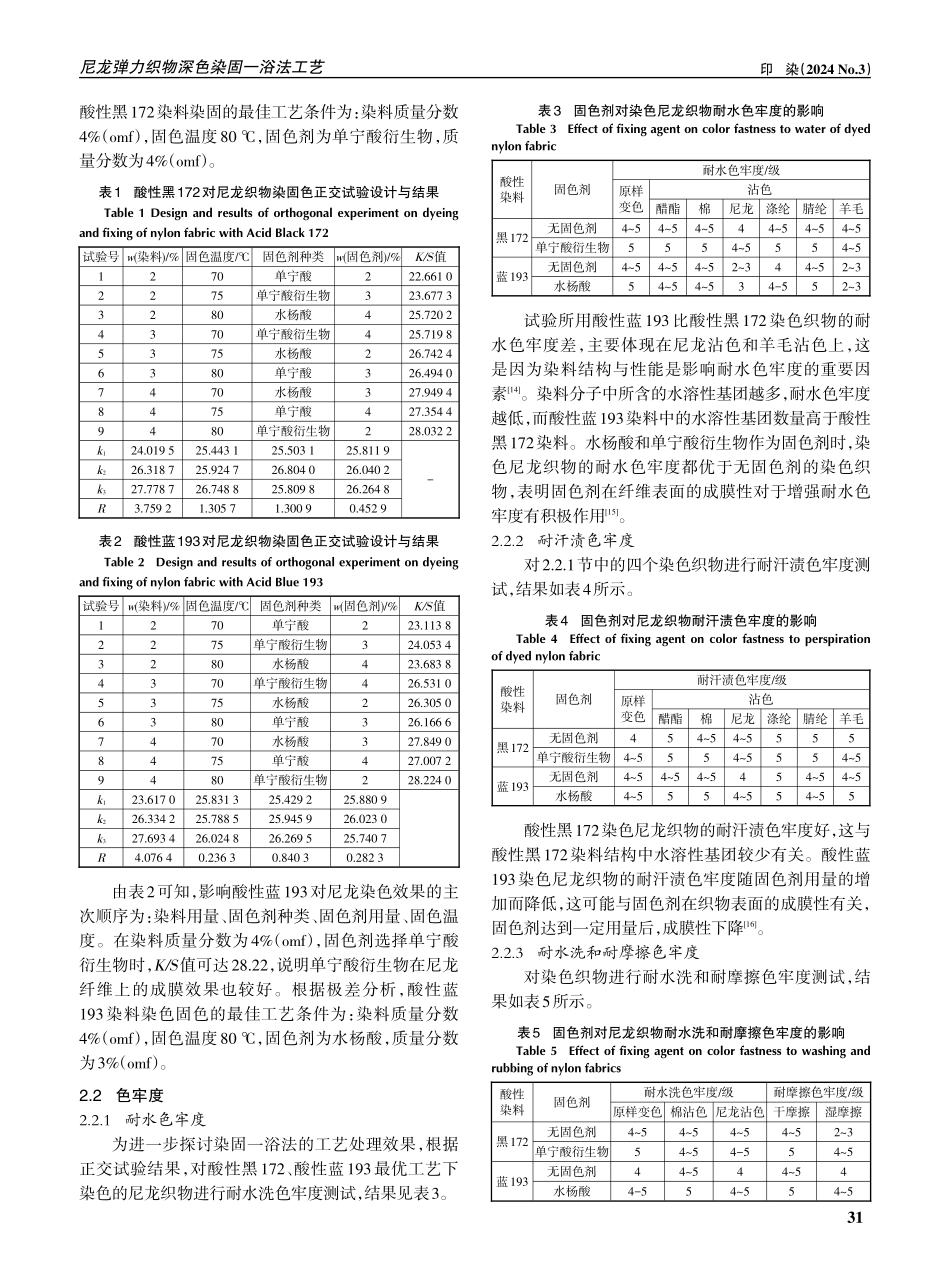

尼龙弹力织物深色染固一浴法工艺印染(2024No.3)尼龙弹力织物深色染固一浴法工艺张琪1,刘丽佳1,宋树严2,张维1,3æèççöø÷÷1.河北科技大学纺织服装学院,河北石家庄050018;2.天津三环化工有限公司,天津300384;3.河北省纺织服装技术创新中心,河北石家庄050018摘要:为提高尼龙弹力织物染深色时的色牢度,选取酸性黑172、酸性蓝193为深色染料代表,研究染料用量、固色剂种类、染固同浴法工艺对织物染色深度及染色牢度的影响。结果表明:染料用量是影响染色深度的关键因素,酸性黑172和酸性蓝193的染料质量分数为4%时,K/S值均达到最大值28.03和28.22。经水杨酸和单宁酸衍生物固色后,织物的耐水、耐汗渍、耐水洗、耐摩擦色牢度均提升0.5级,且织物整体构象未发生变化,比原纤维的结晶度高、结晶完善程度好。动力学分析表明,酸性染料对尼龙纤维的上染过程符合准二级动力学模型,织物与染料之间主要为化学吸附过程。关键词:尼龙弹力织物;酸性染料;染色;固色;色牢度中图分类号:TS193.636文献标志码:BDOI:10.3969/j.yinran.202403002One-bathdyeingandfixingprocessofnylonelasticfabricindarkshadeZHANGQi1,LIULijia1,SONGShuyan2,ZHANGWei1,3æèççççöø÷÷÷÷1.CollegeofTextileandGarment,HebeiUniversityofScience&Technology,Shijiazhuang050018,China;2.TianjinSanhuanChemicalCo.,Ltd.,Tianjin300384,China;3.TechnologyInnovationCenterforTextileandGarmentofHebeiProvince,Shijiazhuang050018,ChinaAbstract:Inordertoimprovethecolorfastnessofnylonelasticfabricsindeepdyeing,AcidBlack172andAcidBlue193areselectedastherepresentativesofdarkdyestostudytheeffectsofdyedosage,typesoffixingagents,andone-bathdyeingandfixingprocessonthedyeingdepthandfastness.Theresultsshowthatthedyedosageisakeyfactoraffectingthedyeingdepth.WhenthedyedosageofAcidBlack172andAcidBlue193is4%,theK/Svaluesreachthemaximumvaluesof28.03and28.22.Afterfixationwithsalicylicacidandtan⁃ninacidderivatives,thecolorfastnessestowater,perspiration,washingandrubbingofthedyednylonarein⁃creasedby0.5levels.Afterdyeing,theoverallconformationofthefabricdoesnotchange,andithasahighercrystallinityandbettercrystallinitycomparedtotheoriginalfiber.Kineticanalysisshowsthatthedyeingpro⁃cessofnylonf...