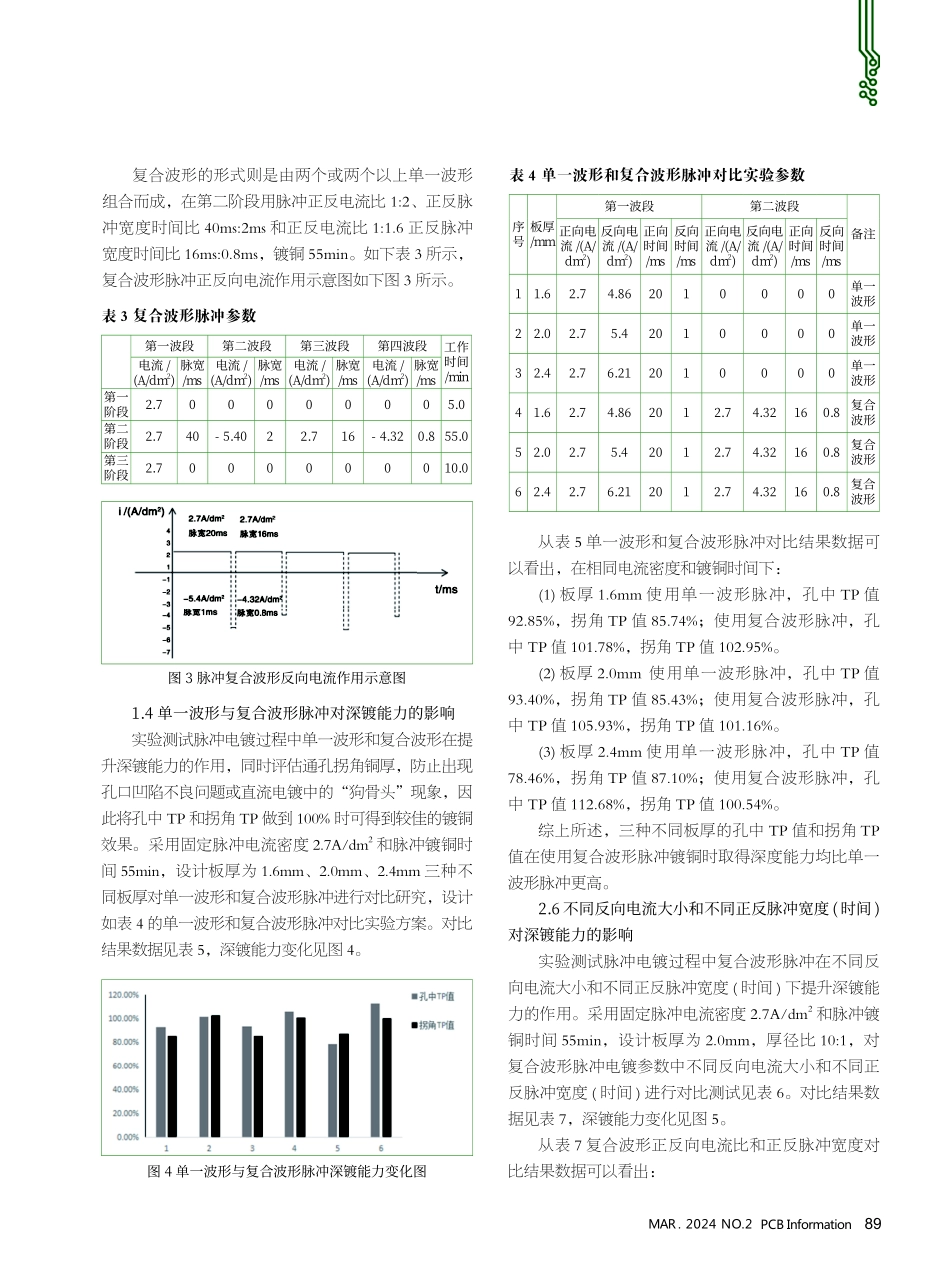

87PCBInformationMAR.2024NO.2莫晓锰陈正军(江西博泉化学有限公司,江西吉安331603)孔生产板,提高电镀的深镀能力的重要办法是采用脉冲电镀技术。随着脉冲技术的应用发展,我们会发现生产板因脉冲波形的设置不合理会导致有孔中铜厚不足或孔口拐角铜厚不足产生的孔口凹陷、外层线路凸起问题,甚至出现因拐角铜厚偏薄导致热冲击测试有在印制电路板孔金属化工艺中,对于高厚径比通脉冲电镀复合波形对孔铜和拐角铜深镀能力的影响EffectofpulseelectroplatingcompositewaveformondeepplatingabilityofholecopperandcornercopperMoXiaomeng,ChenZhengjun【摘要】本文介绍脉冲电镀复合波形参数对通孔板孔中铜厚和拐角铜厚深镀能力的影响,通过对单一波形和复合波形进行对比研究发现复合波形取得的深镀能力比单一波形更好。同时对复合波形中的反向电流和正反向脉冲宽度(时间)对通孔的镀通率做了详细探究,调整复合波形控制脉冲电镀过程中反向电流的大小和正反脉冲宽度(时间),能够调节高厚径比通孔的孔中铜厚和拐角铜厚的深镀能力,其中随着反向电流的增大,孔中铜厚深镀能力逐渐提高,但拐角铜厚深镀能力会有所降低;而随着正反脉冲宽度增加,拐角铜厚深镀能力逐渐降低,但孔中铜厚深镀能力会呈现先增加再降低的抛物线趋势。AbstractThispaperintroducestheeffectofpulseelectroplatingcompositewaveformparametersonthedeepplatingabilityofcopperthicknessandcornercopperthicknessinthroughholeplate.Throughcomparativestudyofsinglewaveformandcompositewaveform,itisfoundthatthedeepplatingabilityofcompositewaveformisbetterthanthatofsinglewaveform.Atthesametime,thereversecurrentandpositiveandnegativepulsewidth(time)inthecompositewaveformarestudiedindetail.Byadjustingthereversecurrentandpositiveandnegativepulsewidth(time)inthepulseelectroplatingprocess,thedeepplatingabilityofthecopperthicknessintheholeandthecornercopperthicknesscanbeadjusted.Withtheincreaseofthereversecurrent,thecopperthicknessanddeepplatingabilityintheholegraduallyincreases,butthecopperthicknessanddeepplatingabilityatthecornerdecreases.Withtheincreaseofpulsewidth,thecopperthicknessanddeepplatingabilityatthecornerdecreasedgradually,butthecopperthicknessanddeepplatingabilityintheholeshowedaparabolictrendoffirstincrea...