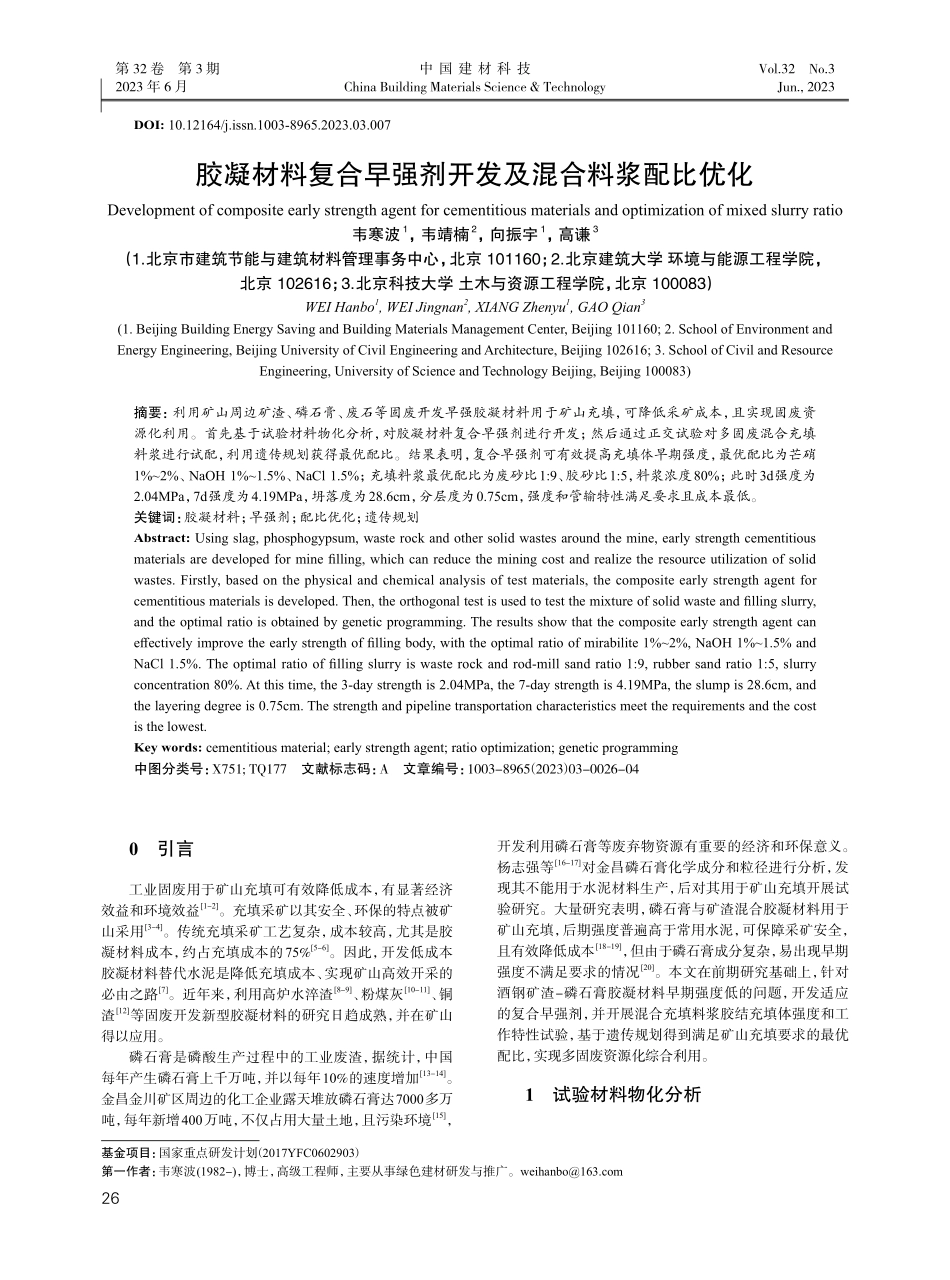

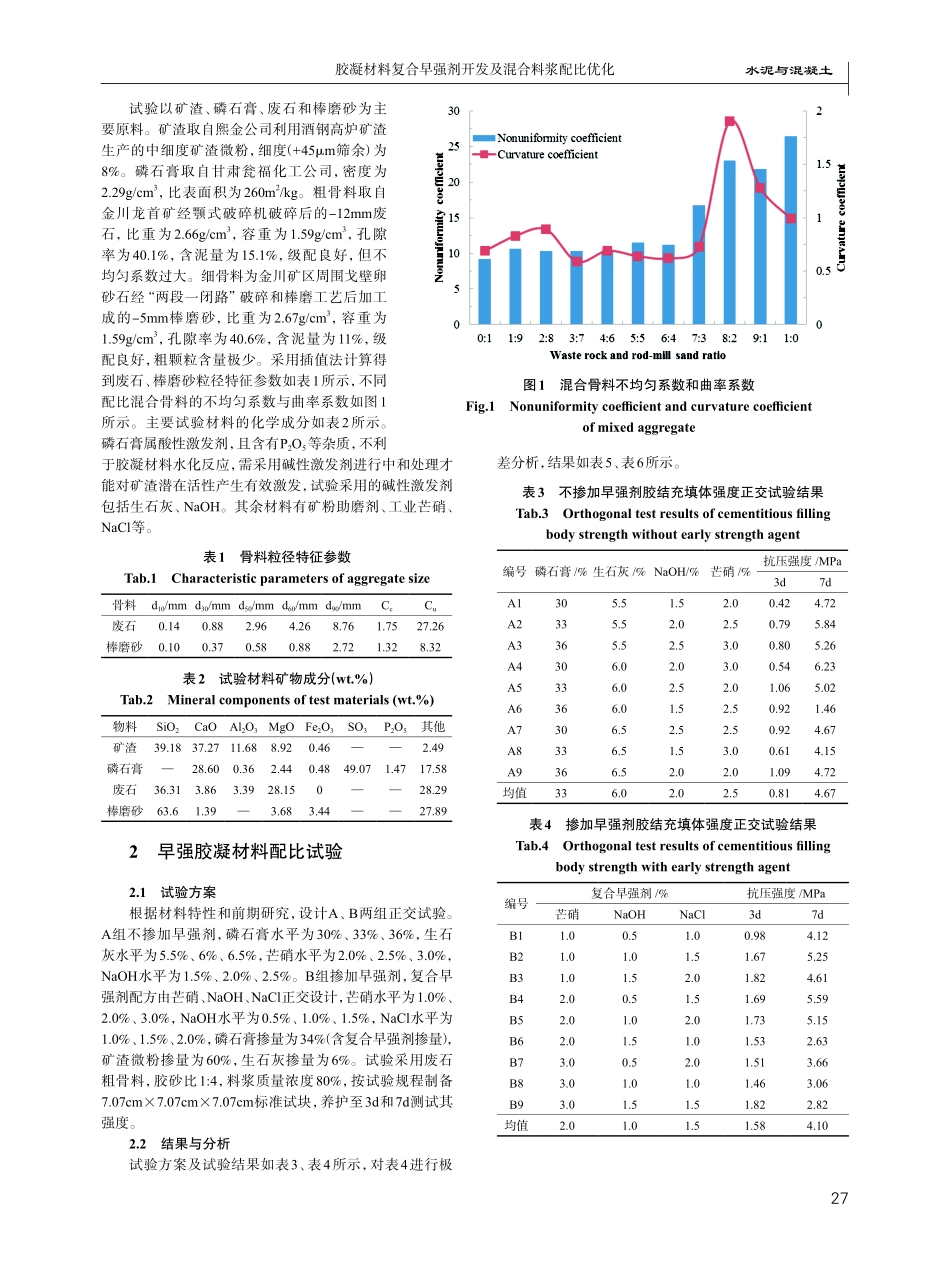

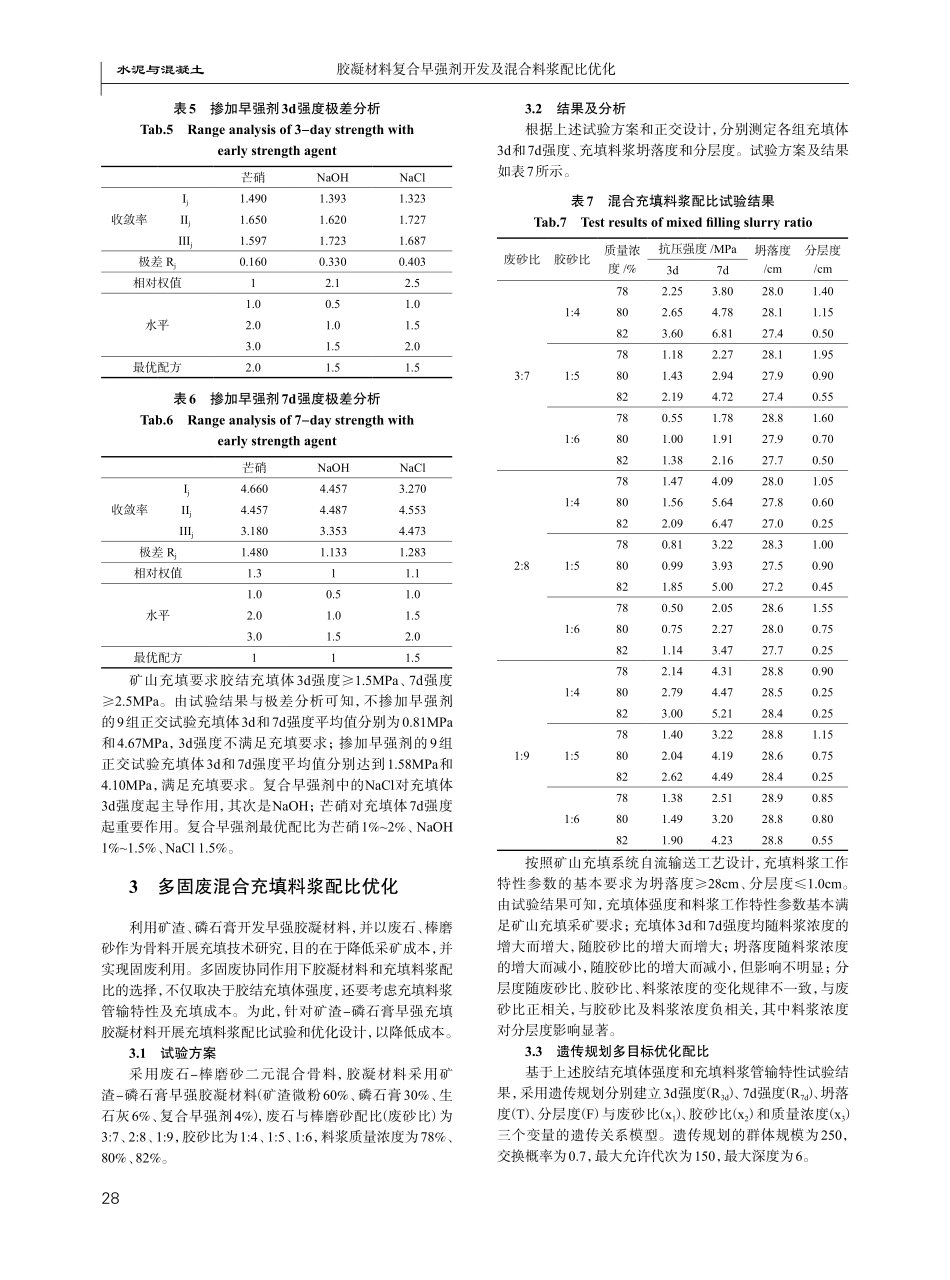

26第32卷第3期2023年6月中国建材科技ChinaBuildingMaterialsScience&TechnologyVol.32No.3Jun.,2023DOI:10.12164/j.issn.1003-8965.2023.03.007胶凝材料复合早强剂开发及混合料浆配比优化Developmentofcompositeearlystrengthagentforcementitiousmaterialsandoptimizationofmixedslurryratio韦寒波1,韦靖楠2,向振宇1,高谦3(1.北京市建筑节能与建筑材料管理事务中心,北京101160;2.北京建筑大学环境与能源工程学院,北京102616;3.北京科技大学土木与资源工程学院,北京100083)WEIHanbo1,WEIJingnan2,XIANGZhenyu1,GAOQian3(1.BeijingBuildingEnergySavingandBuildingMaterialsManagementCenter,Beijing101160;2.SchoolofEnvironmentandEnergyEngineering,BeijingUniversityofCivilEngineeringandArchitecture,Beijing102616;3.SchoolofCivilandResourceEngineering,UniversityofScienceandTechnologyBeijing,Beijing100083)摘要:利用矿山周边矿渣、磷石膏、废石等固废开发早强胶凝材料用于矿山充填,可降低采矿成本,且实现固废资源化利用。首先基于试验材料物化分析,对胶凝材料复合早强剂进行开发;然后通过正交试验对多固废混合充填料浆进行试配,利用遗传规划获得最优配比。结果表明,复合早强剂可有效提高充填体早期强度,最优配比为芒硝1%~2%、NaOH1%~1.5%、NaCl1.5%;充填料浆最优配比为废砂比1:9、胶砂比1:5,料浆浓度80%;此时3d强度为2.04MPa,7d强度为4.19MPa,坍落度为28.6cm,分层度为0.75cm,强度和管输特性满足要求且成本最低。关键词:胶凝材料;早强剂;配比优化;遗传规划Abstract:Usingslag,phosphogypsum,wasterockandothersolidwastesaroundthemine,earlystrengthcementitiousmaterialsaredevelopedforminefilling,whichcanreducetheminingcostandrealizetheresourceutilizationofsolidwastes.Firstly,basedonthephysicalandchemicalanalysisoftestmaterials,thecompositeearlystrengthagentforcementitiousmaterialsisdeveloped.Then,theorthogonaltestisusedtotestthemixtureofsolidwasteandfillingslurry,andtheoptimalratioisobtainedbygeneticprogramming.Theresultsshowthatthecompositeearlystrengthagentcaneffectivelyimprovetheearlystrengthoffillingbody,withtheoptimalratioofmirabilite1%~2%,NaOH1%~1.5%andNaCl1.5%.Theoptimalratiooffillingslurryiswasterockandrod-millsandratio1:9,rubbersandrati...