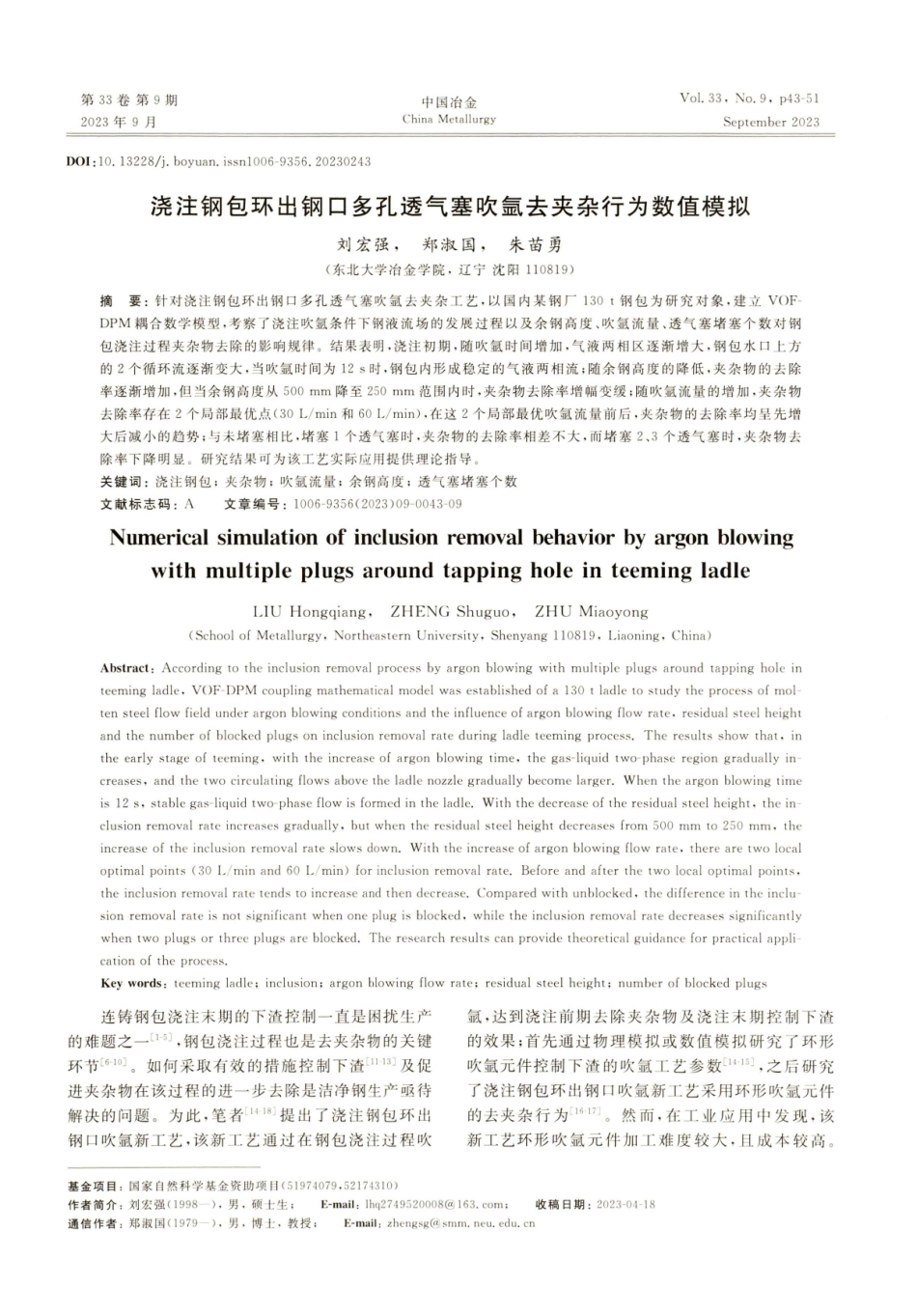

D0I:10.132ssn1006-9356.20230243September20232023年9月ChinaMetallurgy中国冶金第33卷第9期Vol.33,No.9.p43-51浇注钢包环出钢口多孔透气塞吹氩去夹杂行为数值模拟刘宏强,郑淑国,朱苗勇(东北大学冶金学院,辽宁沈阳110819)摘要:针对浇注钢包环出钢口多孔透气塞吹氩去夹杂工艺,以国内某钢厂130t钢包为研究对象,建立VOF-DPM耦合数学模型,考察了浇注吹氩条件下钢液流场的发展过程以及余钢高度、吹氩流量、透气塞堵塞个数对钢包浇注过程夹杂物去除的影响规律。结果表明,浇注初期,随吹氩时间增加,气液两相区逐渐增大,钢包水口上方的2个循环流逐渐变大,当吹氩时间为12s时,钢包内形成稳定的气液两相流;随余钢高度的降低,夹杂物的去除率逐渐增加,但当余钢高度从500mm降至250mm范围内时,夹杂物去除率增幅变缓;随吹氩流量的增加,夹杂物去除率存在2个局部最优点(30L/min和60L/min),在这2个局部最优吹氩流量前后,夹杂物的去除率均呈先增大后减小的趋势;与未堵塞相比,堵塞1个透气塞时,夹杂物的去除率相差不大,而堵塞2、3个透气塞时,夹杂物去除率下降明显。研究结果可为该工艺实际应用提供理论指导。关键词:浇注钢包;夹杂物;吹氩流量;余钢高度;透气塞堵塞个数文献标志码:A文章编号:1006-9356(2023)09-0043-09NumericalsimulationofinclusionremovalbehaviorbyargonblowingwithmultipleplugsaroundtappingholeinteemingladleLIUHongqiang,2ZHENGShuguo,2ZHUMiaoyong(SchoolofMetallurgy,NortheasternUniversity,Shenyang110819,Liaoning,China)Abstract:Accordingtotheinclusionremovalprocessbyargonblowingwithmultipleplugsaroundtappingholeinteemingladle,VOF-DPMcouplingmathematicalmodelwasestablishedofa130tladletostudytheprocessofmol-tensteelflowfieldunderargonblowingconditionsandtheinfluenceofargonblowingflowrate,residualsteelheightandthenumberofblockedplugsoninclusionremovalrateduringladleteemingprocess.Theresultsshowthat,intheearlystageofteeming,withtheincreaseofargonblowingtime,thegas-liquidtwo-phaseregiongraduallyin-creases,andthetwocirculatingflowsabovetheladlenozzlegraduallybecomelarger.Whentheargonblowingtimeis12s,stablegas-liquidtwo-phaseflowisformedintheladle.Withthedecreaseoftheresidualsteelheight,thein-clusionremovalrateincreasesgradually,butwhen...