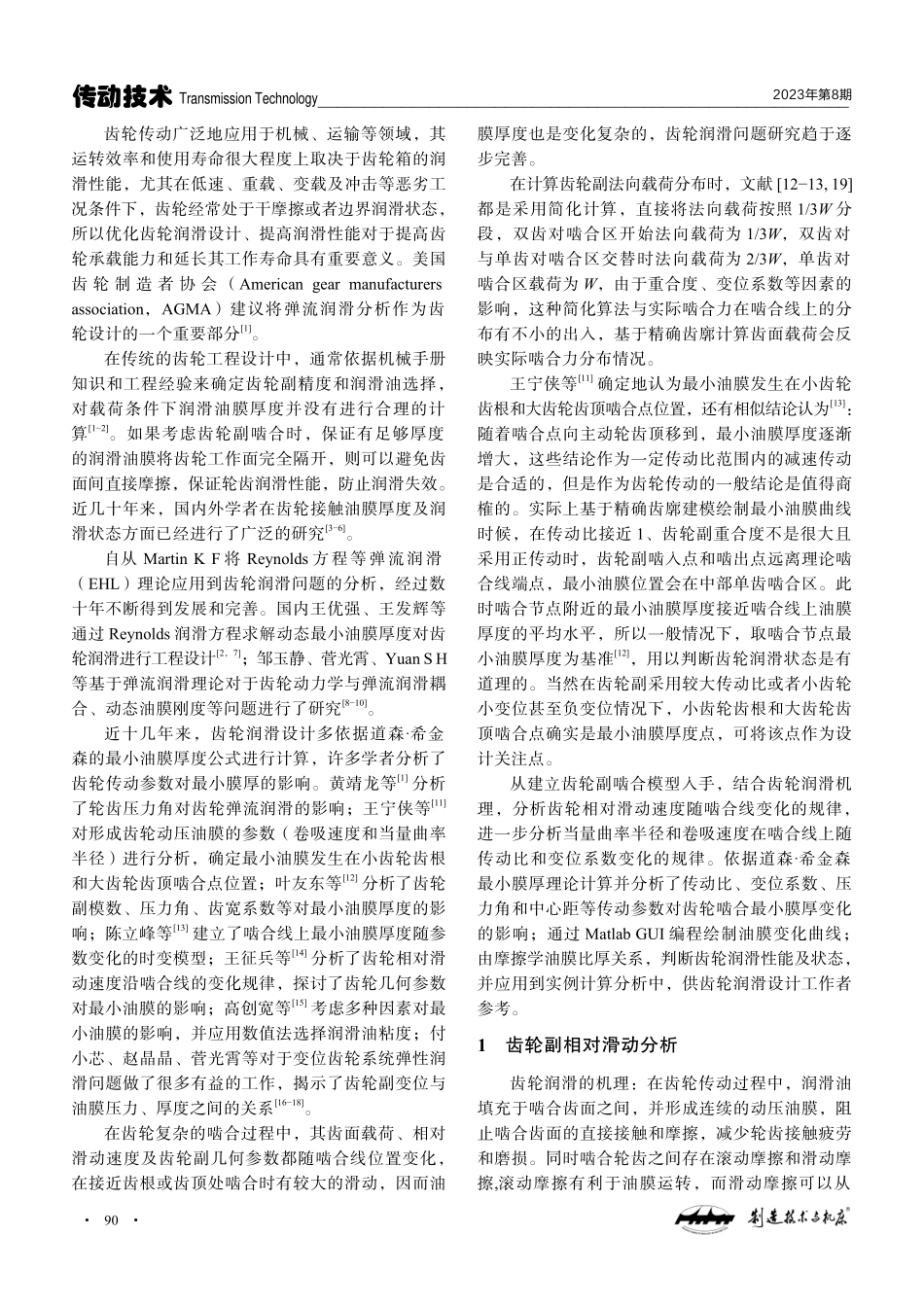

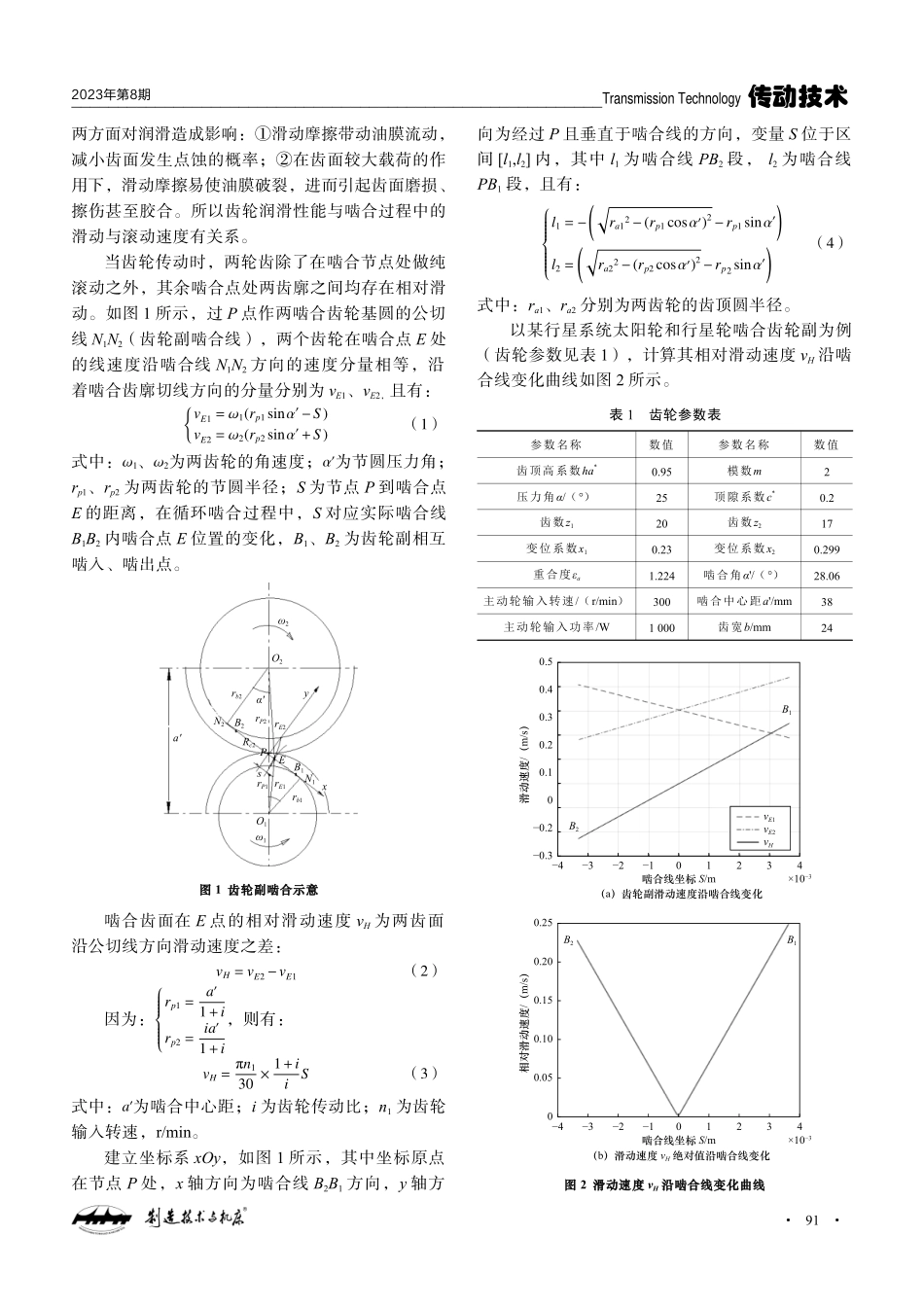

渐开线圆柱齿轮传动弹流润滑工程设计分析曹东江尹飞行(庆安集团有限公司,陕西西安710077)摘要:通过分析齿轮润滑机理,揭示了齿轮副啮合线上相对滑动速度的变化规律。根据道森·希金森最小油膜经验公式,对影响齿轮润滑性能的关键因素—当量曲率半径和卷吸速度随传动比和变位系数变化的规律进行分析,基于精确齿廓计算出齿面载荷沿啮合线分布情况。通过编程计算相应的关系曲线图,分析了传动比、变位系数、压力角及中心距等齿轮设计参数对齿轮副最小油膜厚度的影响,结果表明:传动比会使最小油膜厚度曲线倾斜和旋转,变位系数决定了膜厚曲线沿啮合线的起始点和终止点,并引起齿轮副中心距变化间接影响最小油膜厚度,中心距、压力角与最小膜厚的关系是正相关关系。最后,根据膜厚比关系判断齿轮润滑状态,通过实例计算曲线可见,该齿轮副最小油膜厚度点并未发生在小齿轮齿根与大齿轮齿顶啮合点处,因此采用啮合节点油膜厚比来判定齿轮润滑状态。以上所得结论对于齿轮传动弹流润滑设计提供了一定的参考依据。关键词:齿轮传动;齿轮润滑设计;最小油膜厚度;膜厚比;弹流润滑中图分类号:TH132.41文献标识码:ADOI:10.19287/j.mtmt.1005-2402.2023.08.013EngineeringdesignandanalysisofEHLforinvolutecylindricalspurgeartransmissionCAODongjiang,YINFeixing(Qing'anGroupCo.,Ltd.,Xi'an710077,CHN)Abstract:Throughtheanalysisofgearlubricationmechanism,thechangelawofrelativeslidingspeedonthemeshinglineofgearpairisrevealed.AccordingtoDowson-Higginson'sempiricalformulaofminimumoilfilm,thelawsofequivalentcurvatureradiusandentrainmentspeedchangingwithtransmissionratioandmodificationcoefficient,whicharekeyfactorsaffectinggearlubricationperformance,areanalyzed.Basedonaccuratetoothprofile,thedistributionoftoothsurfaceloadalongthemeshinglineiscalculated.Theinfluenceofgeardesignparameterssuchastransmissionratio,modificationcoefficient,pressureangleandcenterdistanceontheminimumoilfilmthicknessofgearpairisanalyzedbyprogrammingandcalculatingthecorrespondingrelationshipcurves.Theresultsshowthatthetransmissionratiomakestheminimumoilfilmthicknesscurveinclineandrotate,themodificationcoefficientdeterminesthestartingandendingpointsofthefilmthicknesscurvealongthemeshingline,andc...