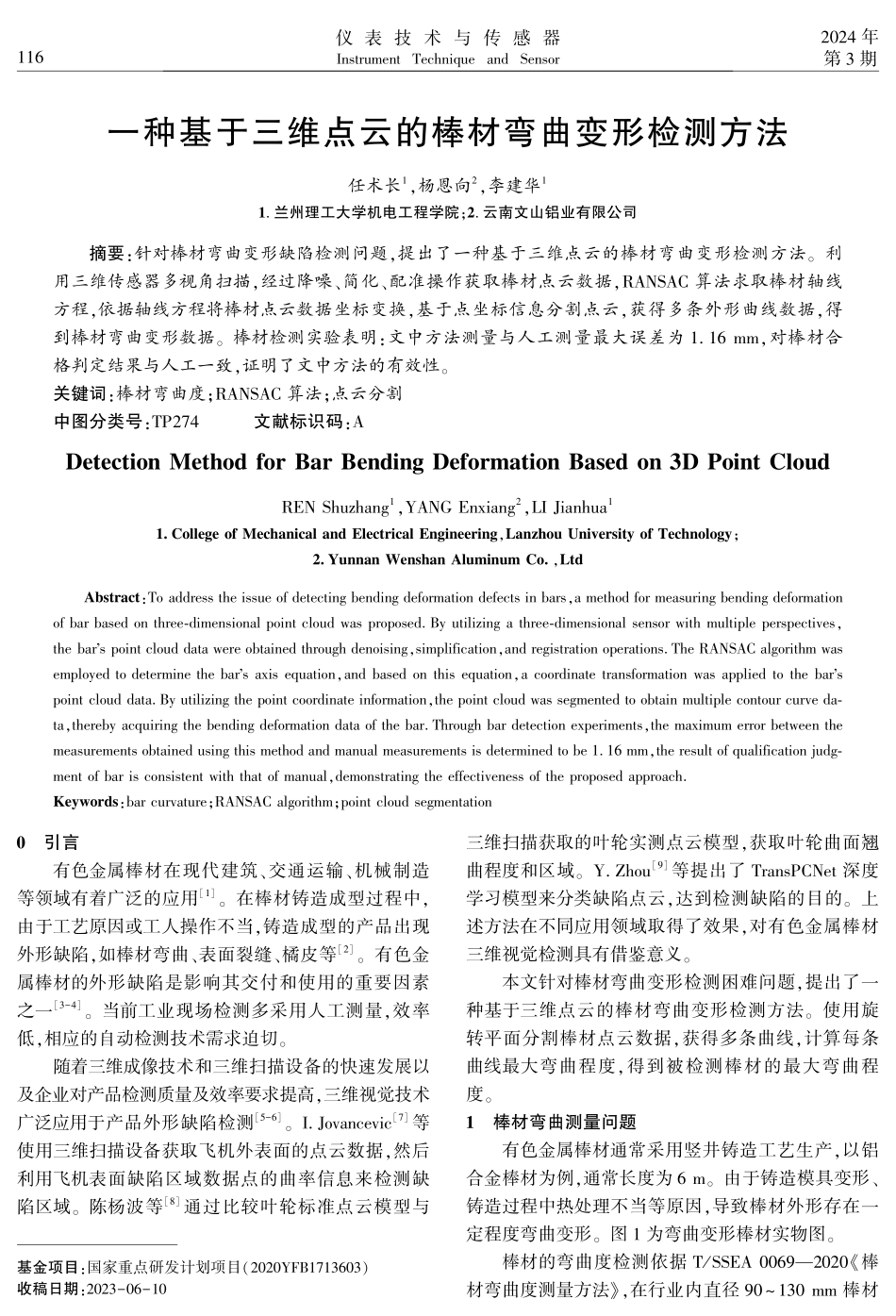

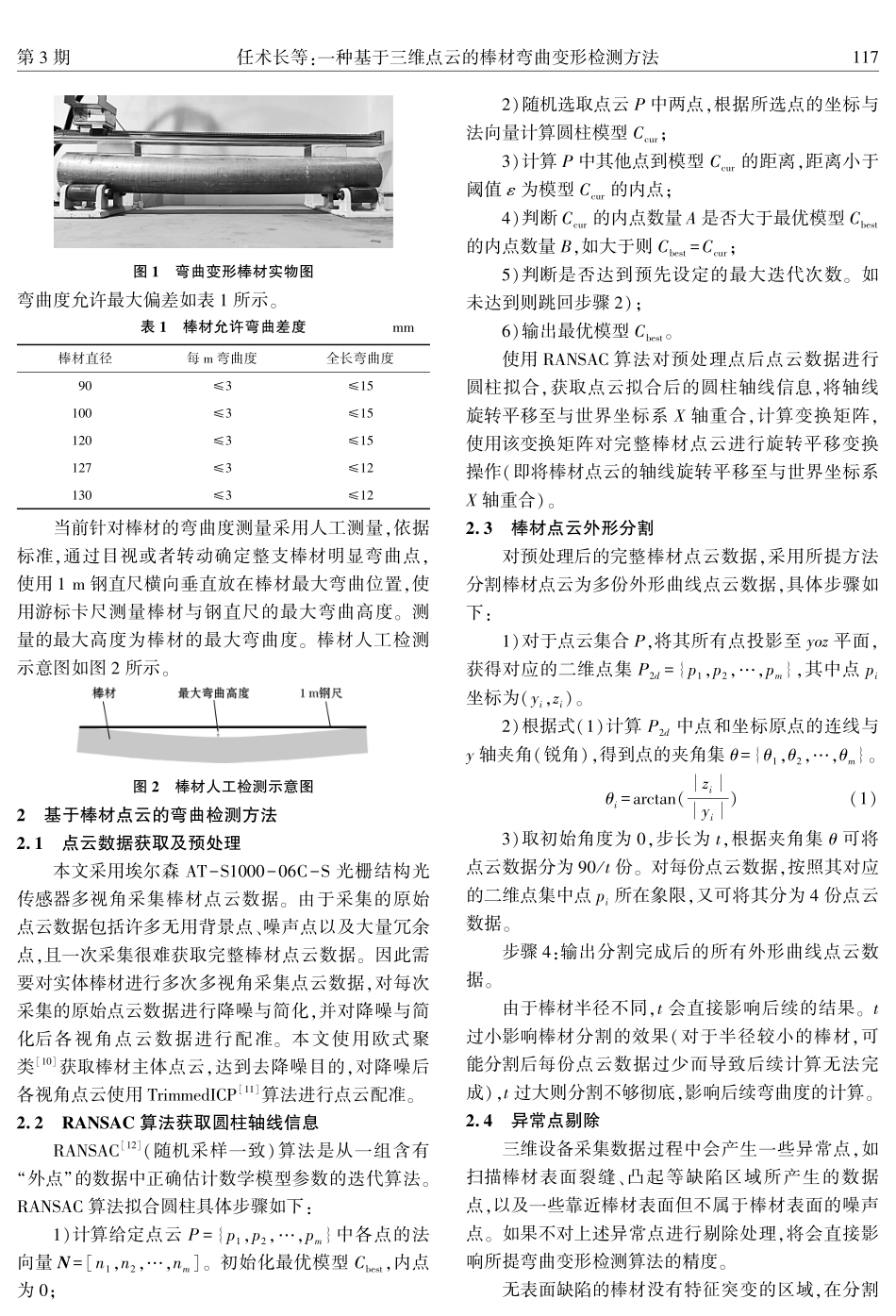

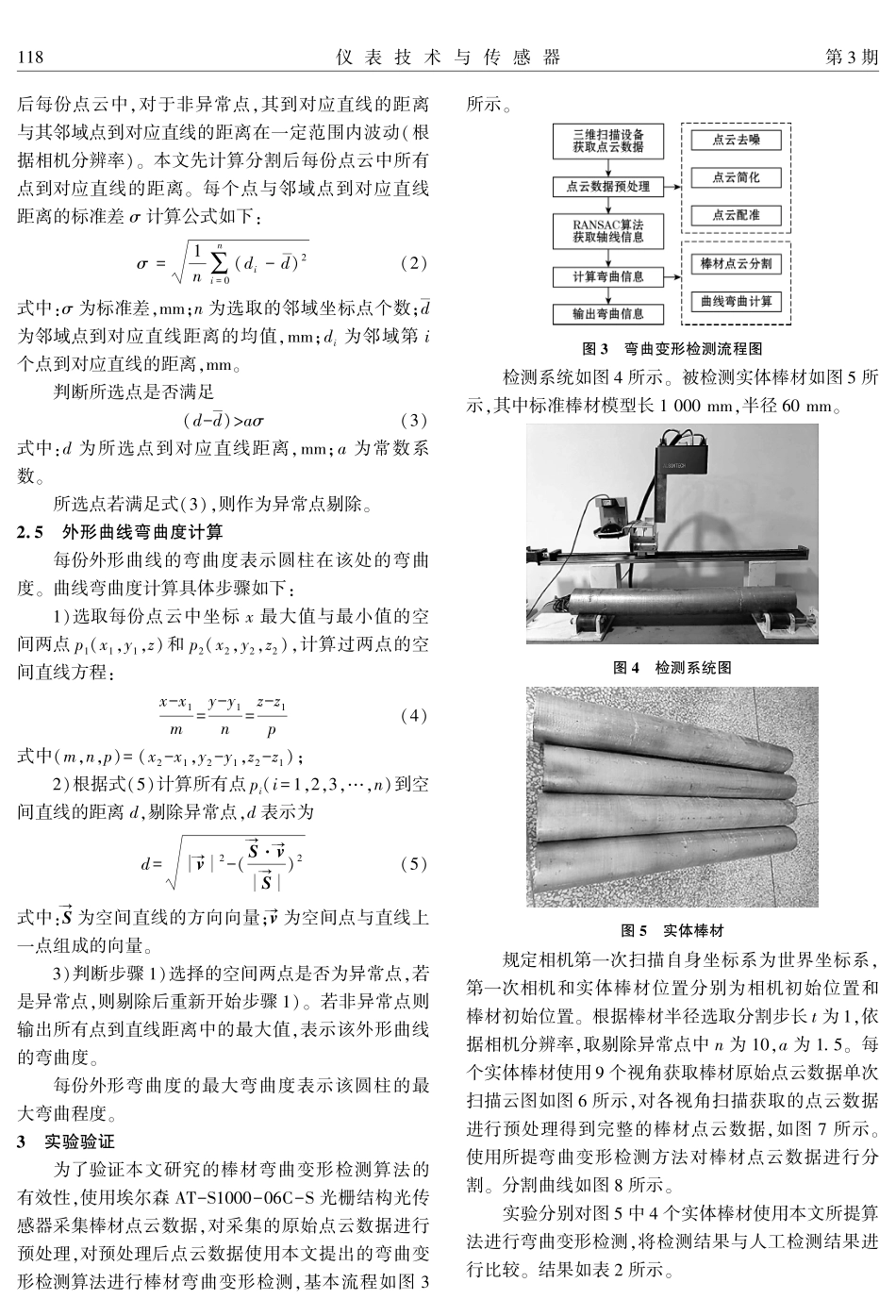

仪表技术与传感器InstrumentTechniqueandSensor2024年第3期基金项目:国家重点研发计划项目(2020YFB1713603)收稿日期:2023-06-10一种基于三维点云的棒材弯曲变形检测方法任术长1,杨恩向2,李建华11.兰州理工大学机电工程学院;2.云南文山铝业有限公司摘要:针对棒材弯曲变形缺陷检测问题,提出了一种基于三维点云的棒材弯曲变形检测方法。利用三维传感器多视角扫描,经过降噪、简化、配准操作获取棒材点云数据,RANSAC算法求取棒材轴线方程,依据轴线方程将棒材点云数据坐标变换,基于点坐标信息分割点云,获得多条外形曲线数据,得到棒材弯曲变形数据。棒材检测实验表明:文中方法测量与人工测量最大误差为1.16mm,对棒材合格判定结果与人工一致,证明了文中方法的有效性。关键词:棒材弯曲度;RANSAC算法;点云分割中图分类号:TP274文献标识码:ADetectionMethodforBarBendingDeformationBasedon3DPointCloudRENShuzhang1,YANGEnxiang2,LIJianhua11.CollegeofMechanicalandElectricalEngineering,LanzhouUniversityofTechnology;2.YunnanWenshanAluminumCo.,LtdAbstract:Toaddresstheissueofdetectingbendingdeformationdefectsinbars,amethodformeasuringbendingdeformationofbarbasedonthree-dimensionalpointcloudwasproposed.Byutilizingathree-dimensionalsensorwithmultipleperspectives,thebarspointclouddatawereobtainedthroughdenoising,simplification,andregistrationoperations.TheRANSACalgorithmwasemployedtodeterminethebarsaxisequation,andbasedonthisequation,acoordinatetransformationwasappliedtothebarspointclouddata.Byutilizingthepointcoordinateinformation,thepointcloudwassegmentedtoobtainmultiplecontourcurveda-ta,therebyacquiringthebendingdeformationdataofthebar.Throughbardetectionexperiments,themaximumerrorbetweenthemeasurementsobtainedusingthismethodandmanualmeasurementsisdeterminedtobe1.16mm,theresultofqualificationjudg-mentofbarisconsistentwiththatofmanual,demonstratingtheeffectivenessoftheproposedapproach.Keywords:barcurvature;RANSACalgorithm;pointcloudsegmentation0引言有色金属棒材在现代建筑、交通运输、机械制造等领域有着广泛的应用[1]。在棒材铸造成型过程中,由于工艺原因或工人操作不当,铸造成型的产品出现外形缺陷,如棒材弯曲、表面裂缝、橘皮等[2]。有色金属棒材的外形缺...