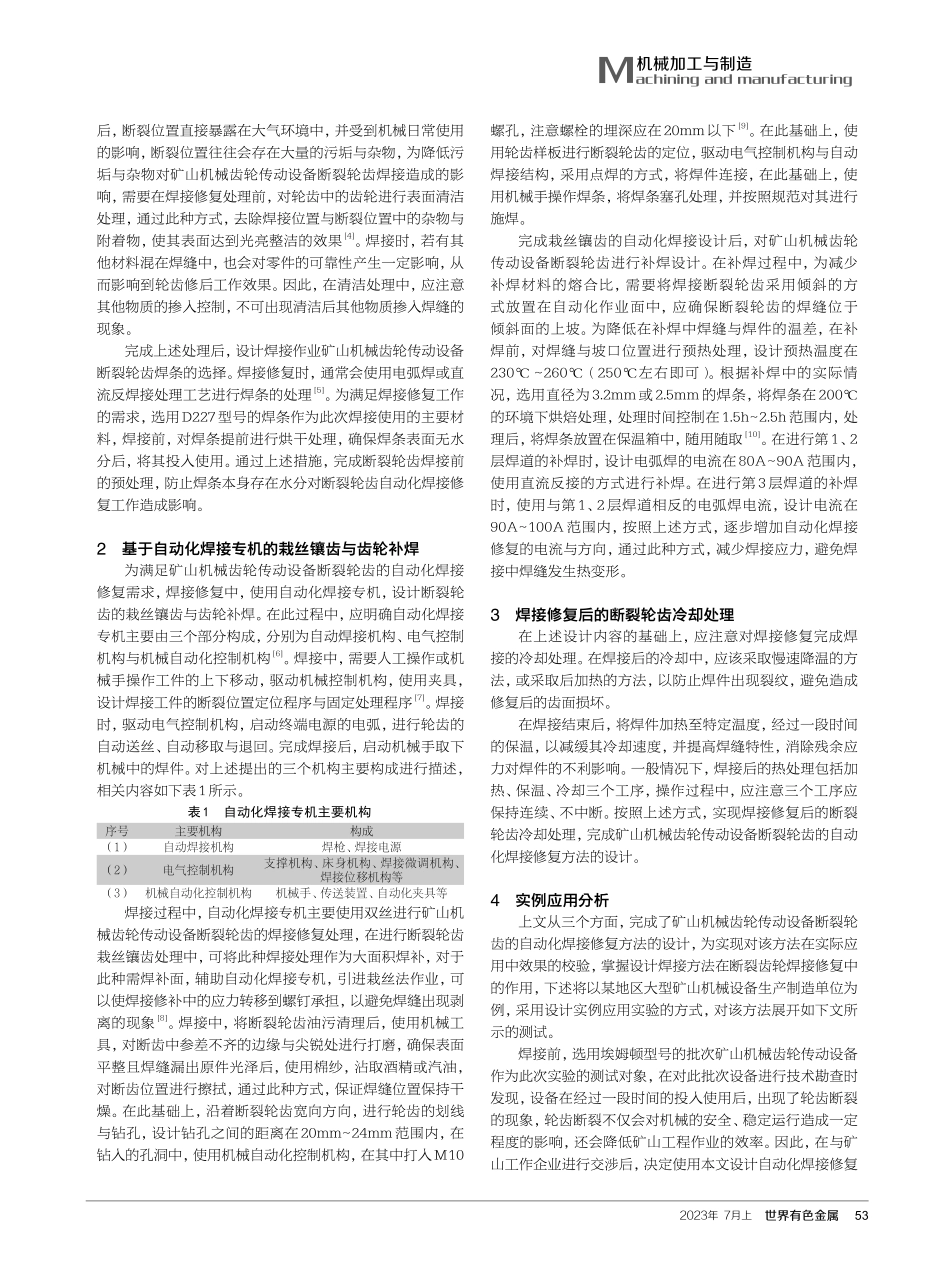

世界有色金属2023年7月上52机械加工与制造Machiningandmanufacturing矿山机械齿轮传动设备断裂轮齿的自动化焊接修复技术孙亮,王亮(兰州石化职业技术大学,甘肃兰州730207)摘要:为提高断裂轮齿焊缝强度,降低焊接修复后焊件不合格率,开展矿山机械齿轮传动设备断裂轮齿的自动化焊接修复方法的设计研究。为了达到最大的延迟冷却速度,并降低冷开裂现象的发生概率,在对断裂轮齿焊接和修复前,按照规范对断裂轮齿中的焊缝进行预热、清洁等处理;使用自动化焊接专机,设计断裂轮齿的栽丝镶齿与齿轮补焊;采取慢速降温或后加热的方法,设计焊接修复后的断裂轮齿冷却处理,防止焊件出现裂纹,完成自动化焊接修复技术的设计。以某地区大型矿山机械设备生产制造单位为例,设计实例应用实验,实验结果证明:该方法可以在提高断裂轮齿焊缝强度的同时,将自动焊接修复加工的不合格率控制在一个相对较低的水平。关键词:矿山;修复技术;自动化焊接;断裂轮齿;传动设备;机械齿轮中图分类号:TG457.25文献标识码:A文章编号:1002-5065(2023)13-0052-3AutomaticWeldingRepairTechnologyforBrokenGearTeethofMiningMachineryGearTransmissionEquipmentSUNLiang,WANGLiang(LanzhouPetrochemicalUniversityofVocationalTechnology,Lanzhou730207,China)Abstract:Inordertoimprovetheweldstrengthoffracturedgearteethandreducetheunqualifiedrateofweldedpartsafterweldingrepair,thedesignandresearchofautomaticweldingrepairmethodsforfracturedgearteethinminingmachinerygeartransmissionequipmentarecarriedout.Inordertoachievethemaximumdelayedcoolingrateandreducetheprobabilityofcoldcracking,preheatingandcleaningoftheweldsinthefracturedgearteethshouldbecarriedoutaccordingtospecificationsbeforeweldingandrepairingthem;Usinganautomatedweldingmachine,designwireembeddingandgearrepairweldingforbrokengearteeth;Adoptingslowcoolingorpostheatingmethods,designingcoolingtreatmentforfracturedgearteethafterweldingrepairtopreventcracksintheweldedparts,andcompletingthedesignofautomatedweldingrepairtechnology.Takingalarge-scaleminingmachineryandequipmentproductionandmanufacturingunitinacertainregionasanexample,anapplicationexperimentwasdesigned.Theexperimentalresultsshowedthatthismethodcanimprovethestr...