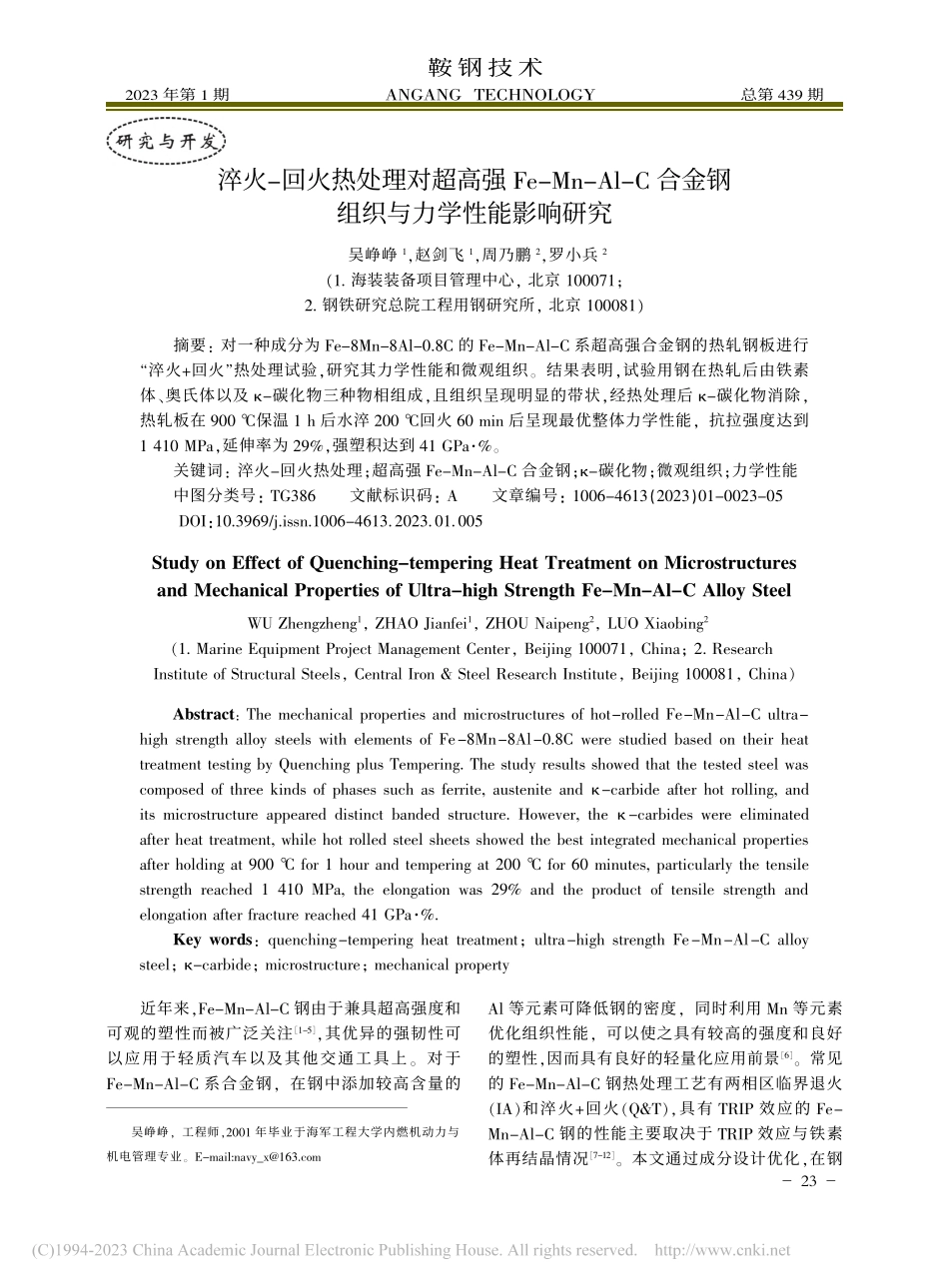

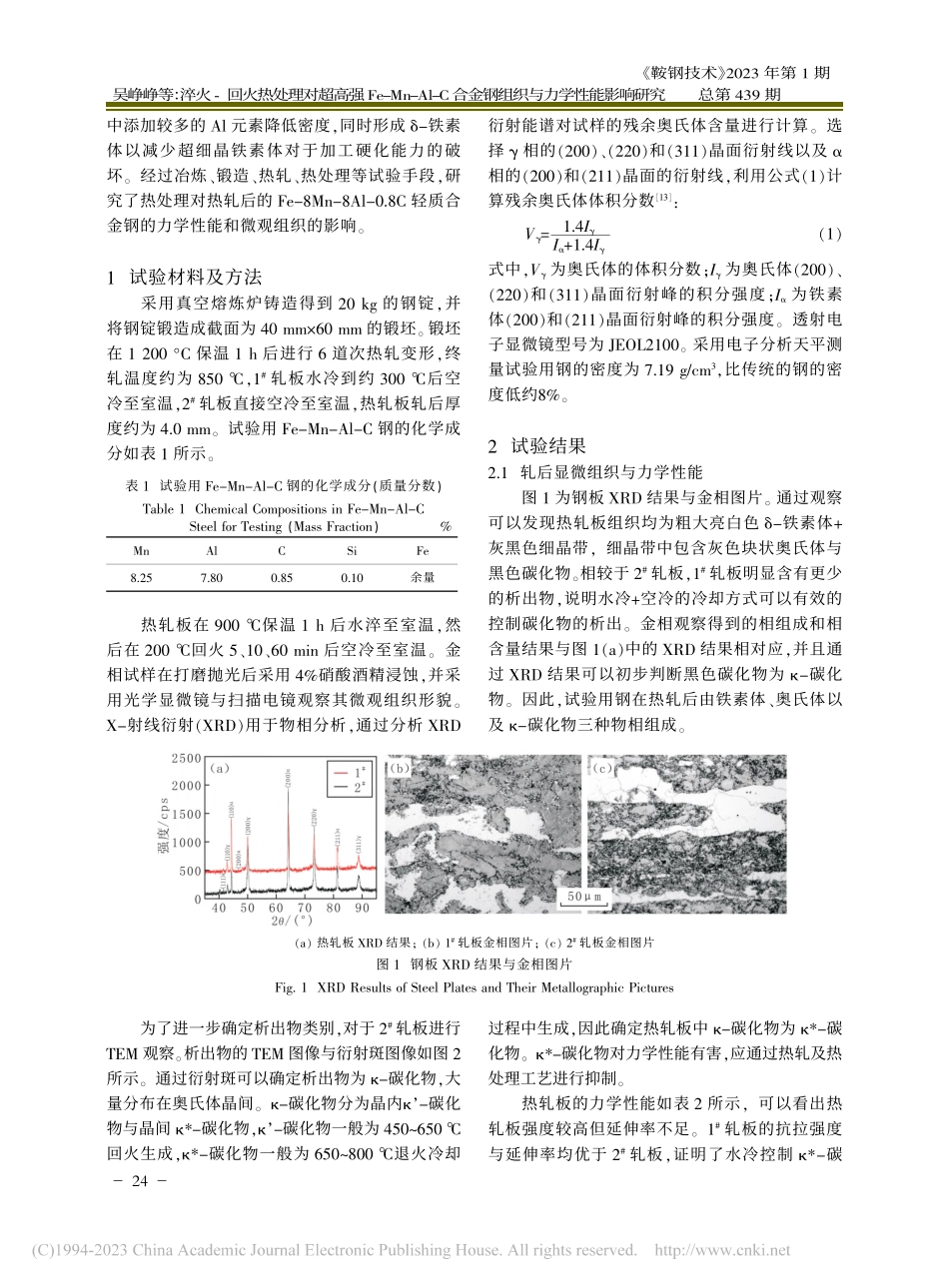

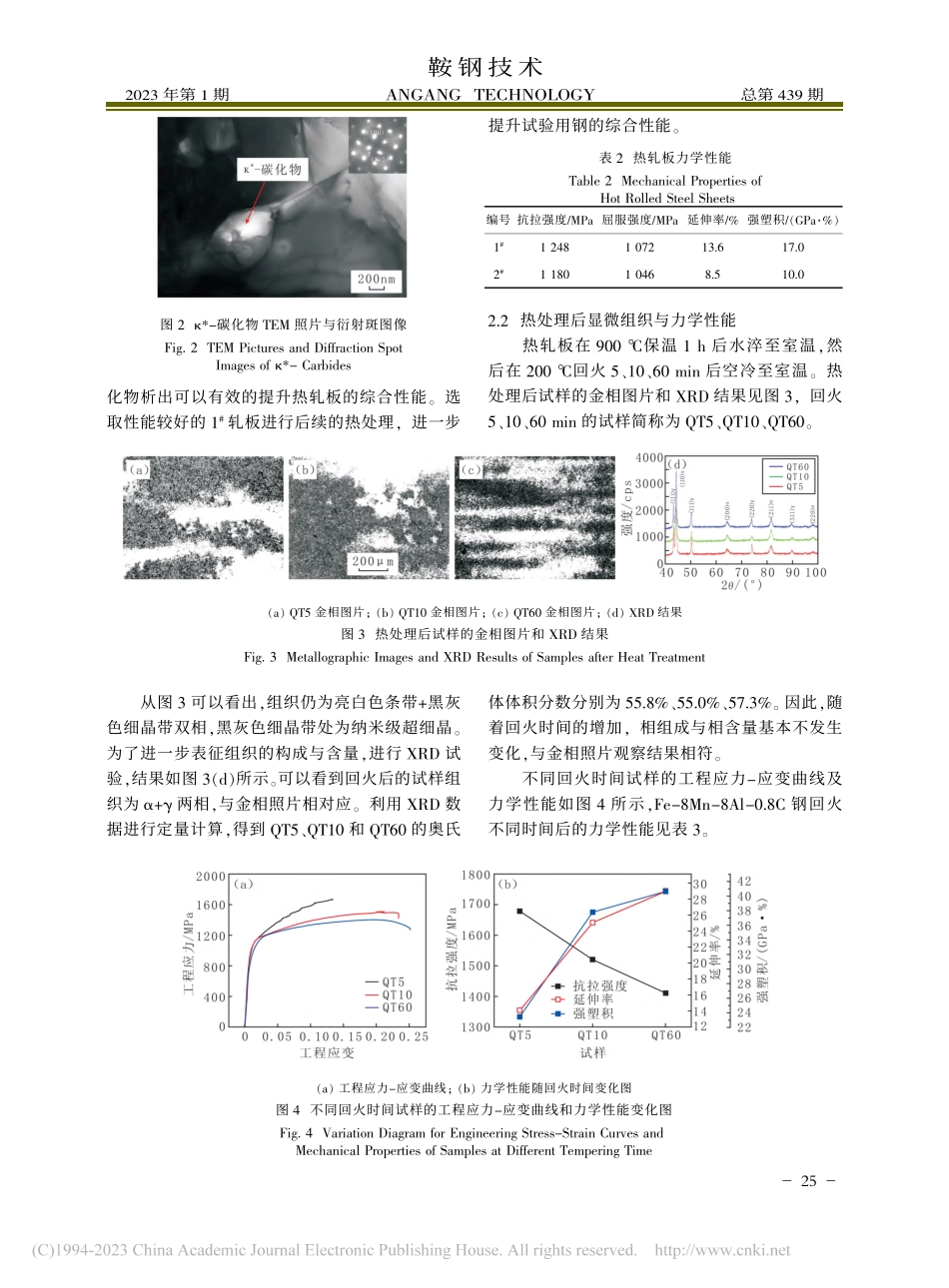

吴峥峥,工程师,2001年毕业于海军工程大学内燃机动力与机电管理专业。E-mail:navy_x@163.com淬火-回火热处理对超高强Fe-Mn-Al-C合金钢组织与力学性能影响研究吴峥峥1,赵剑飞1,周乃鹏2,罗小兵2(1.海装装备项目管理中心,北京100071;2.钢铁研究总院工程用钢研究所,北京100081)摘要:对一种成分为Fe-8Mn-8Al-0.8C的Fe-Mn-Al-C系超高强合金钢的热轧钢板进行“淬火+回火”热处理试验,研究其力学性能和微观组织。结果表明,试验用钢在热轧后由铁素体、奥氏体以及κ-碳化物三种物相组成,且组织呈现明显的带状,经热处理后κ-碳化物消除,热轧板在900℃保温1h后水淬200℃回火60min后呈现最优整体力学性能,抗拉强度达到1410MPa,延伸率为29%,强塑积达到41GPa·%。关键词:淬火-回火热处理;超高强Fe-Mn-Al-C合金钢;κ-碳化物;微观组织;力学性能中图分类号:TG386文献标识码:A文章编号:1006-4613(2023)01-0023-05DOI:10.3969/j.issn.1006-4613.2023.01.005StudyonEffectofQuenching-temperingHeatTreatmentonMicrostructuresandMechanicalPropertiesofUltra-highStrengthFe-Mn-Al-CAlloySteelWUZhengzheng1,ZHAOJianfei1,ZHOUNaipeng2,LUOXiaobing2(1.MarineEquipmentProjectManagementCenter,Beijing100071,China;2.ResearchInstituteofStructuralSteels,CentralIron&SteelResearchInstitute,Beijing100081,China)Abstract:Themechanicalpropertiesandmicrostructuresofhot-rolledFe-Mn-Al-Cultra-highstrengthalloysteelswithelementsofFe-8Mn-8Al-0.8CwerestudiedbasedontheirheattreatmenttestingbyQuenchingplusTempering.Thestudyresultsshowedthatthetestedsteelwascomposedofthreekindsofphasessuchasferrite,austeniteandκ-carbideafterhotrolling,anditsmicrostructureappeareddistinctbandedstructure.However,theκ-carbideswereeliminatedafterheattreatment,whilehotrolledsteelsheetsshowedthebestintegratedmechanicalpropertiesafterholdingat900℃for1hourandtemperingat200℃for60minutes,particularlythetensilestrengthreached1410MPa,theelongationwas29%andtheproductoftensilestrengthandelongationafterfracturereached41GPa·%.Keywords:quenching-temperingheattreatment;ultra-highstrengthFe-Mn-Al-Calloysteel;κ-carbide;microstructure;mechanicalproperty近年来,Fe-Mn-Al-C钢由于兼...