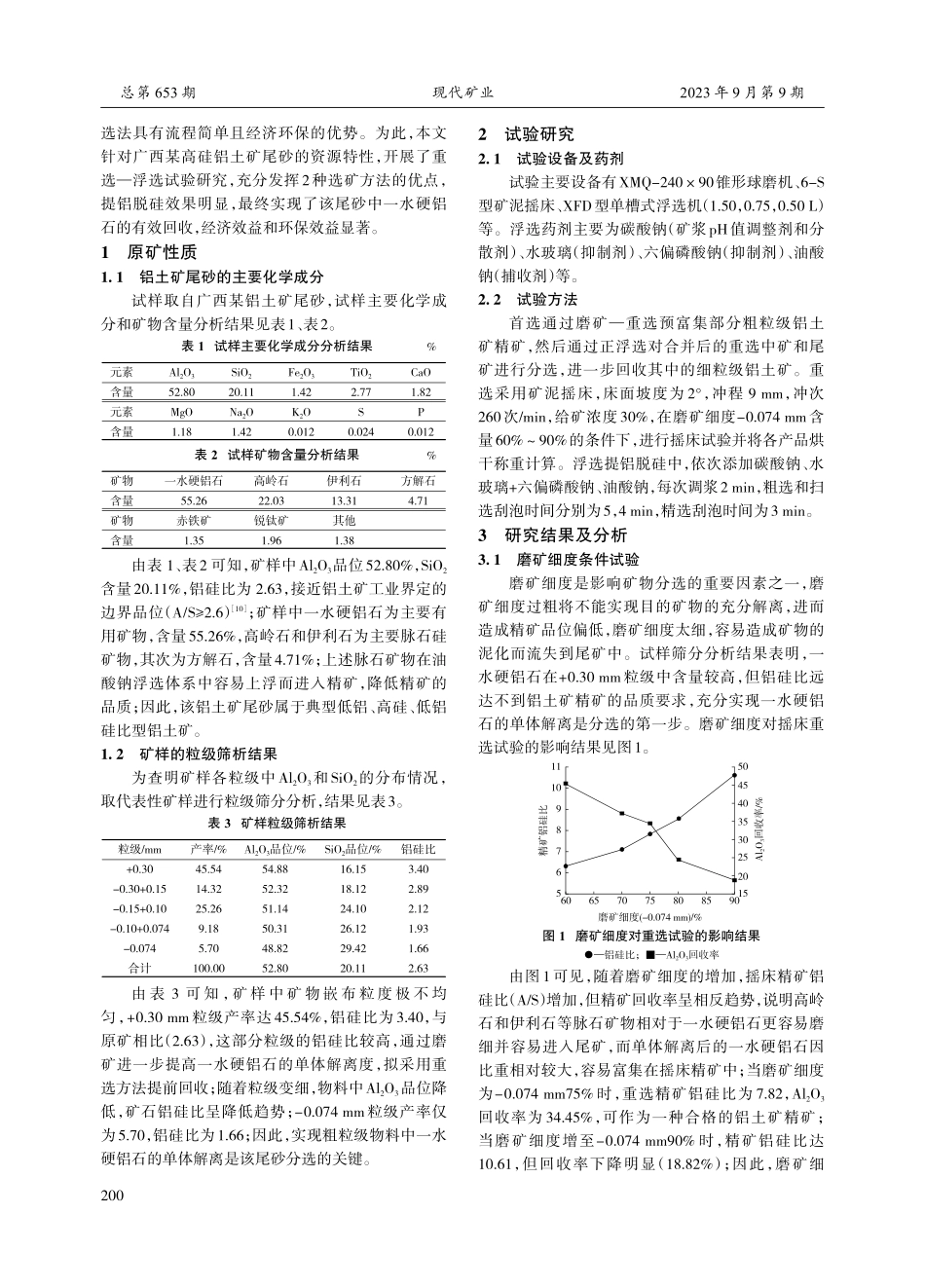

龚祥(2001—),男,650031云南省昆明市。广西某高硅铝土矿尾砂分选试验研究龚祥1郭秀兰1李苏琦1袁加巧1余安美1丁湛1柏少军1,2(1.昆明理工大学国土资源工程学院;2.云南省战略金属矿产资源绿色分离与富集重点实验室)摘要广西某高硅铝土矿为实现其尾砂中含铝矿物的回收利用,进行了选矿工艺试验研究。试验结果表明:在磨矿细度为-0.074mm75%时,经1次重选,重选中矿、尾矿合并后进行1粗1扫3精1精扫、中矿顺序返回的闭路正浮选脱硅流程,获得了Al2O3品位65.80%、铝硅比7.95、Al2O3综合回收率68.98%的铝土矿精矿,重选—浮选联合工艺流程的提铝脱硅效果显著,可为类似低铝高硅型铝土矿资源的开发利用提供技术支撑。关键词高硅铝土矿重选正浮选脱硅联合工艺流程DOI:10.3969/j.issn.1674-6082.2023.09.046ExperimentalStudyonTailingsSeparationofHigh-silicaBauxiteinGuangxiGONGXiang1GUOXiulan1LISuqi1YUANJiaqiao1YUAnmei1DINGZhan1BAIShaojun1,2(1.FacultyofLandandResourcesEngineering,KunmingUniversityofScienceandTechnology;2.YunnanProvincialKeyLaboratoryofGreenSeparationandEnrichmentofStrategicMetalMineralResources)AbstractInordertorealizetherecoveryandutilizationofaluminum-containingmineralsinthetail⁃ingsofhigh-siliconbauxiteinGuangxi,thebeneficiationprocesstestwascarriedout.Thetestresultsshowedthatwhenthegrindingfinenesswas-0.074mm75%,theclosed-circuitpositiveflotationdesilica⁃tionprocessofoneroughing,onescavenging,threecleaningandonecleaningscavengingwascarriedoutaf⁃teronegravityseparationandthecombinationofgravityseparationmiddleoreandtailings.Thebauxitecon⁃centratewithAl2O3gradeof65.80%,Al/Siratioof7.95andAl2O3comprehensiverecoveryrateof68.98%wasobtained.Thecombinedprocessofgravityseparationandflotationhasasignificanteffectonaluminumextractionanddesilication,whichcanprovidetechnicalsupportforthedevelopmentandutilizationofsimi⁃larlow-aluminaandhigh-silicabauxiteresources.Keywordshighsilicabauxite,gravityseparation,positivefloatationdesilication,combinedprocess总第653期2023年9月第9期现代矿业MODERNMININGSerialNo.653September.2023中国的铝土矿资源储量约为2.65亿t,约占全球总储量的10%,主要分布在贵州、广西、云南...