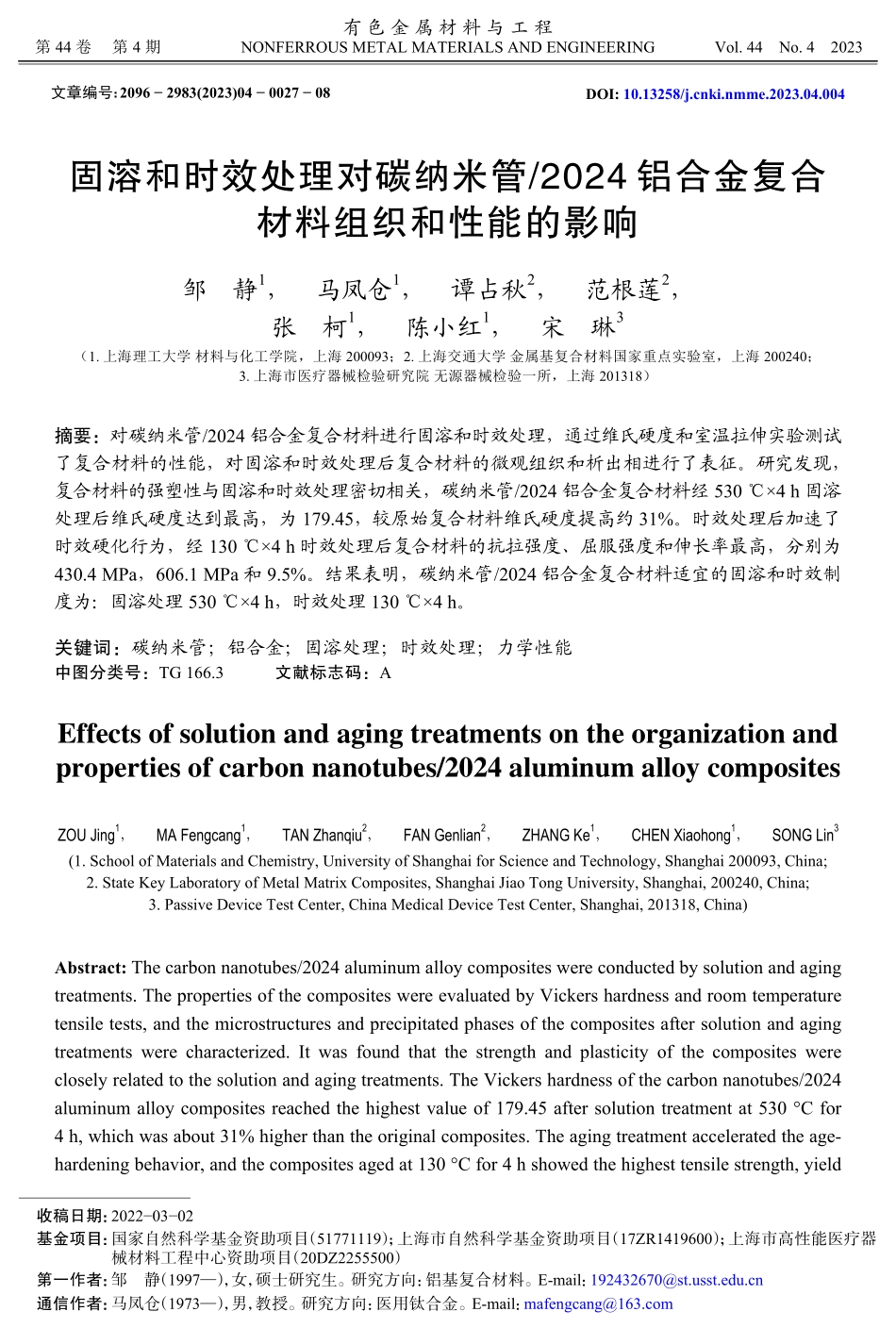

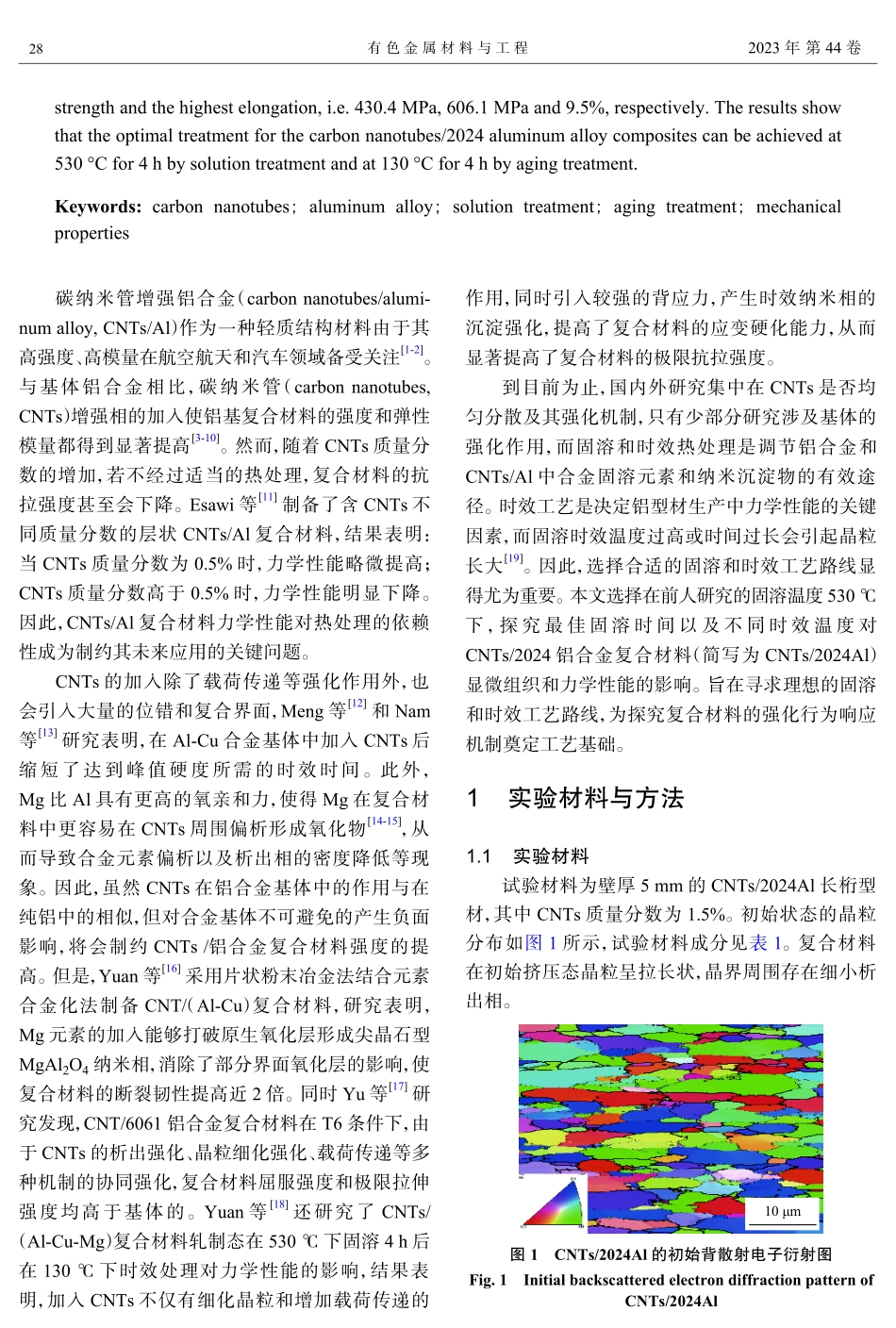

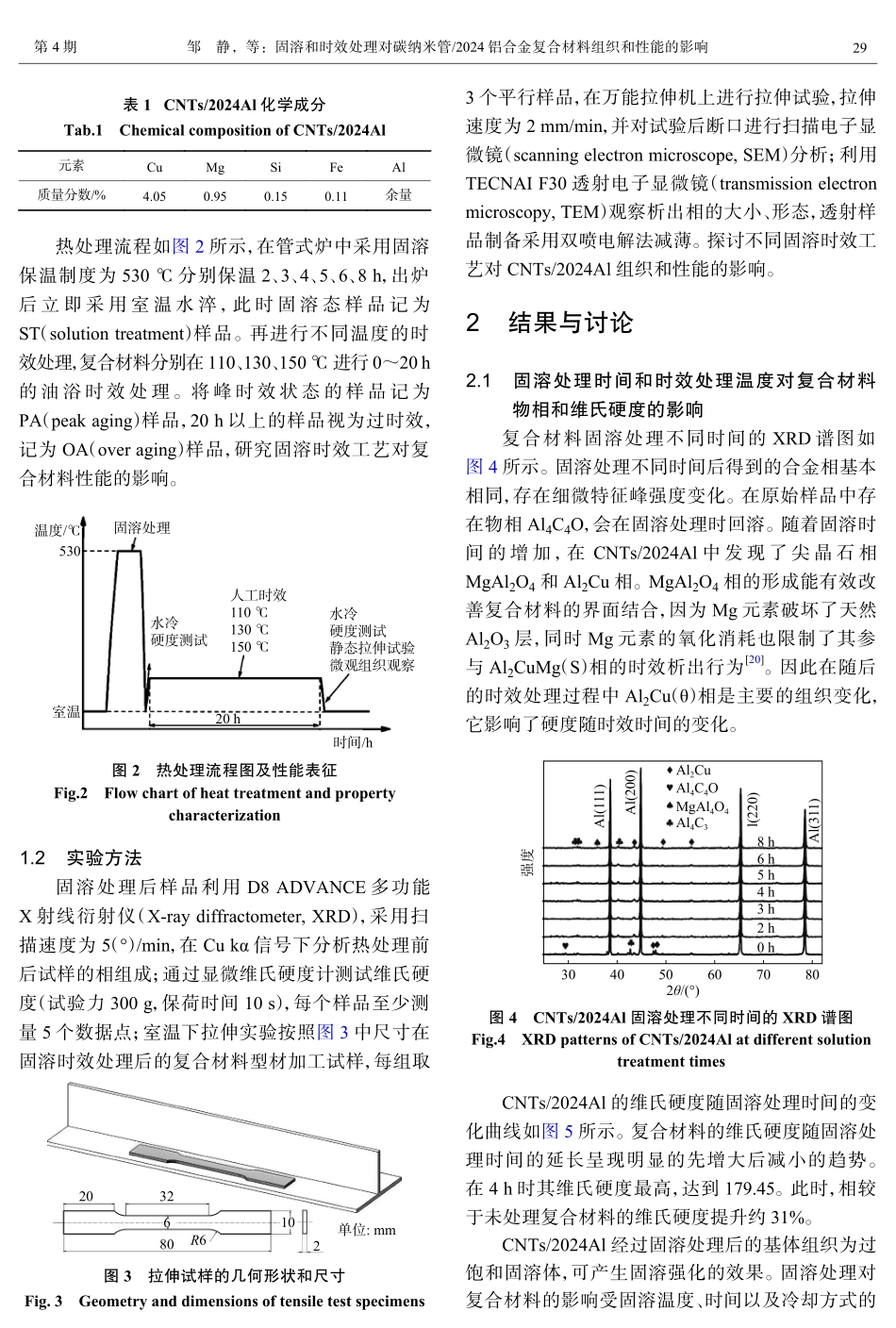

文章编号:2096−2983(2023)04−0027−08DOI:10.13258/j.cnki.nmme.2023.04.004固溶和时效处理对碳纳米管/2024铝合金复合材料组织和性能的影响邹静1,马凤仓1,谭占秋2,范根莲2,张柯1,陈小红1,宋琳3(1.上海理工大学材料与化工学院,上海200093;2.上海交通大学金属基复合材料国家重点实验室,上海200240;3.上海市医疗器械检验研究院无源器械检验一所,上海201318)摘要:对碳纳米管/2024铝合金复合材料进行固溶和时效处理,通过维氏硬度和室温拉伸实验测试了复合材料的性能,对固溶和时效处理后复合材料的微观组织和析出相进行了表征。研究发现,复合材料的强塑性与固溶和时效处理密切相关,碳纳米管/2024铝合金复合材料经530℃×4h固溶处理后维氏硬度达到最高,为179.45,较原始复合材料维氏硬度提高约31%。时效处理后加速了时效硬化行为,经130℃×4h时效处理后复合材料的抗拉强度、屈服强度和伸长率最高,分别为430.4MPa,606.1MPa和9.5%。结果表明,碳纳米管/2024铝合金复合材料适宜的固溶和时效制度为:固溶处理530℃×4h,时效处理130℃×4h。关键词:碳纳米管;铝合金;固溶处理;时效处理;力学性能中图分类号:TG166.3文献标志码:AEffectsofsolutionandagingtreatmentsontheorganizationandpropertiesofcarbonnanotubes/2024aluminumalloycompositesZOUJing1,MAFengcang1,TANZhanqiu2,FANGenlian2,ZHANGKe1,CHENXiaohong1,SONGLin3(1.SchoolofMaterialsandChemistry,UniversityofShanghaiforScienceandTechnology,Shanghai200093,China;2.StateKeyLaboratoryofMetalMatrixComposites,ShanghaiJiaoTongUniversity,Shanghai,200240,China;3.PassiveDeviceTestCenter,ChinaMedicalDeviceTestCenter,Shanghai,201318,China)Abstract:Thecarbonnanotubes/2024aluminumalloycompositeswereconductedbysolutionandagingtreatments.ThepropertiesofthecompositeswereevaluatedbyVickershardnessandroomtemperaturetensiletests,andthemicrostructuresandprecipitatedphasesofthecompositesaftersolutionandagingtreatmentswerecharacterized.Itwasfoundthatthestrengthandplasticityofthecompositeswerecloselyrelatedtothesolutionandagingtreatments.TheVickershardnessofthecarbonnanotubes/2024aluminumalloycompositesreachedthehighestvalueof179.45aftersolutiontreatmentat530°Cfor4h,whichwasabout31%higherthantheorigina...