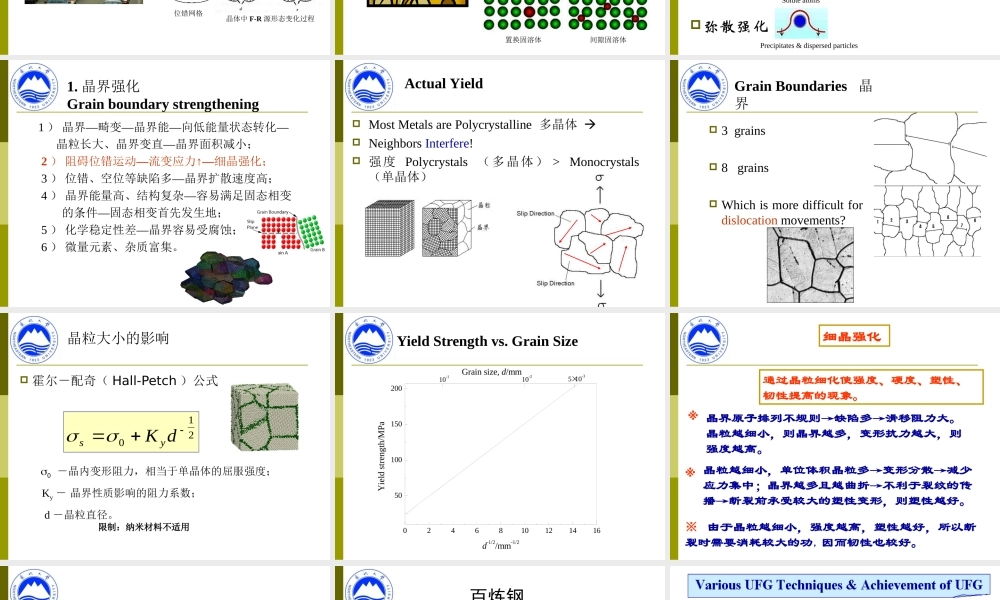

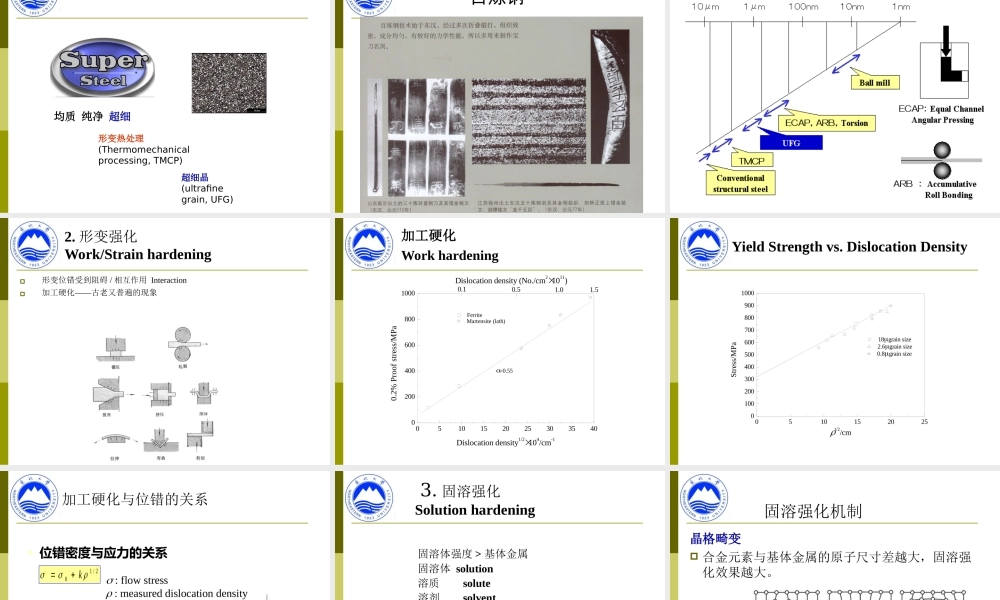

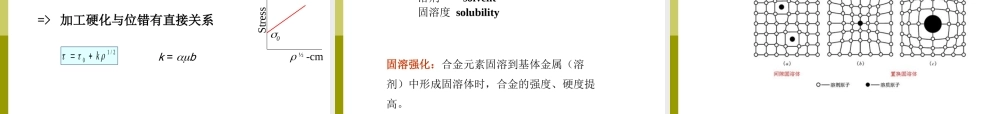

Chap.8材料的组织性能控制8.1金属的强化机制Strengtheningmechanism强度Strength强化Strengthening汽车工业的要求:safer,lighter,stronger3因素:新设计/材料选择/新制造方法强度高、成形性好“减重/节能/降低排放/提高安全性”10%weightreduction/6%increaseinefficiencySlipsystemsarefreewaysfordislocations滑移系-位错运动的高速公路滑移与高速公路Slip:TheHighwayAnalogyThreereasonsfortraffic交通阻塞的3种原因:BlockedFreeways(construction)TooManyCarsPedestrians,StoppedCarsTrafficBroken/BlockedFreeways-ConstructionSlip滑移GrainBoundaries晶界滑移与高速公路Slip:TheHighwayAnalogyTrafficTooManyCarsSlip滑移DislocationDensity位错密度滑移与高速公路Slip:TheHighwayAnalogy位错网格晶体中F-R源形态变化过程TrafficPedestrians,StoppedCarsSlip滑移Solute溶质原子Impurities杂质Secondphaseparticles第二相粒子滑移与高速公路Slip:TheHighwayAnalogy置换固溶体间隙固溶体Al合金第二相主要强化机制Strengtheningmechanisms晶界强化应变强化-加工硬化固溶强化弥散强化SoluteatomsPrecipitates&dispersedparticlesInteractingdislocationsGBstrengthening1.晶界强化Grainboundarystrengthening1)晶界—畸变—晶界能—向低能量状态转化—晶粒长大、晶界变直—晶界面积减小;2)阻碍位错运动—↑流变应力—细晶强化;3)位错、空位等缺陷多—晶界扩散速度高;4)晶界能量高、结构复杂—容易满足固态相变的条件—固态相变首先发生地;5)化学稳定性差—晶界容易受腐蚀;6)微量元素、杂质富集。MostMetalsarePolycrystalline多晶体NeighborsInterfere!强度Polycrystals(多晶体)>Monocrystals(单晶体)ActualYield3grains8grainsWhichismoredifficultfordislocationmovements?GrainBoundaries晶界晶粒大小的影响霍尔-配奇(Hall-Petch)公式210dKys0-晶内变形阻力,相当于单晶体的屈服强度;Ky-晶界性质影响的阻力系数;d-晶粒直径。限制:纳米材料不适用YieldStrengthvs.GrainSize024681012141650100150200Yieldstrength/MPad-1/2/mm-1/2510-310-210-1Grainsize,d/mm细晶强化通过晶粒细化使强度、硬度、塑性、韧性提高的现象。晶界原子排列不规则→缺陷多→滑移阻力大。晶粒越细小,则晶界越多,变形抗力越大,则强度越高。※※晶粒越细小,单位体积晶...