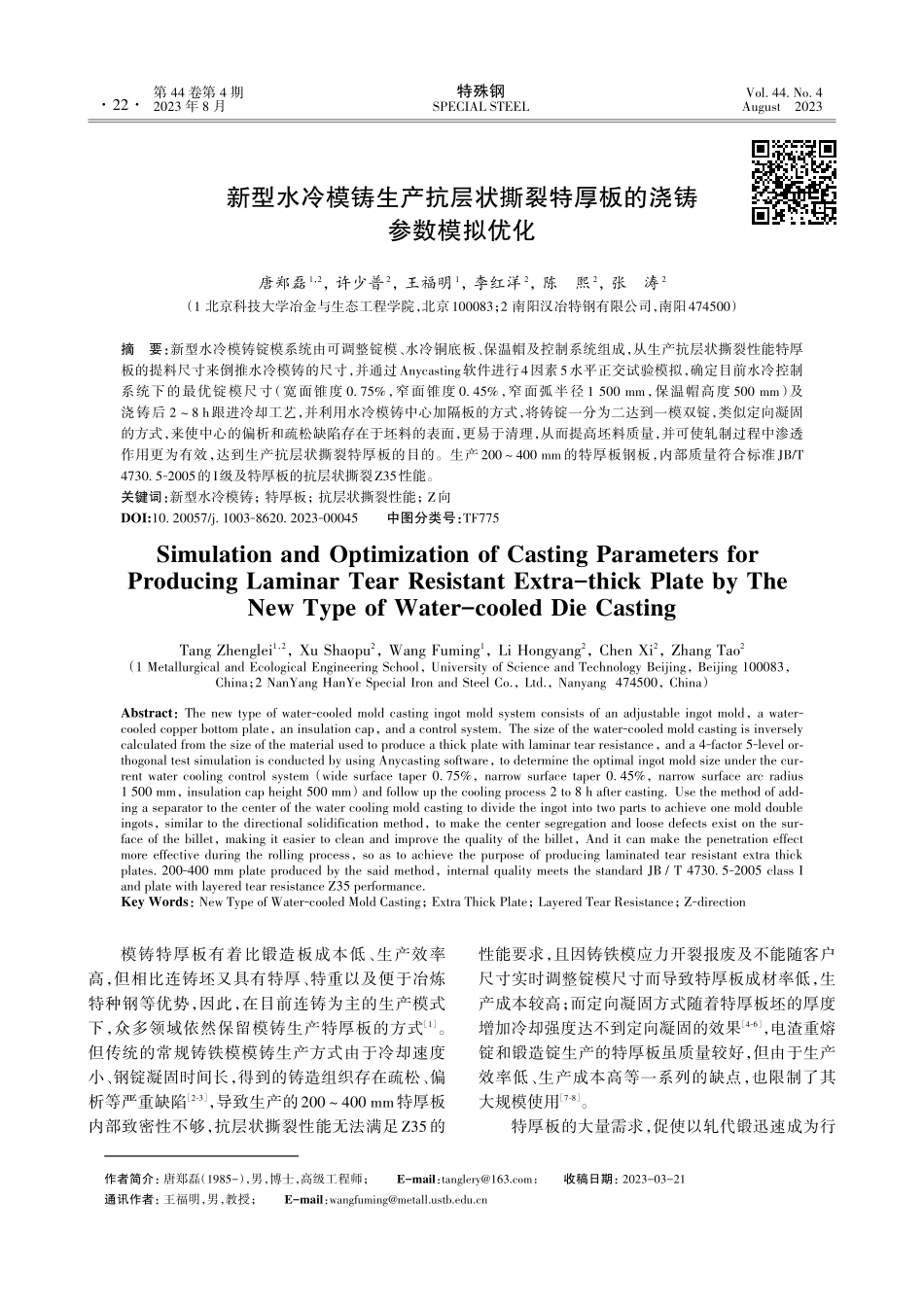

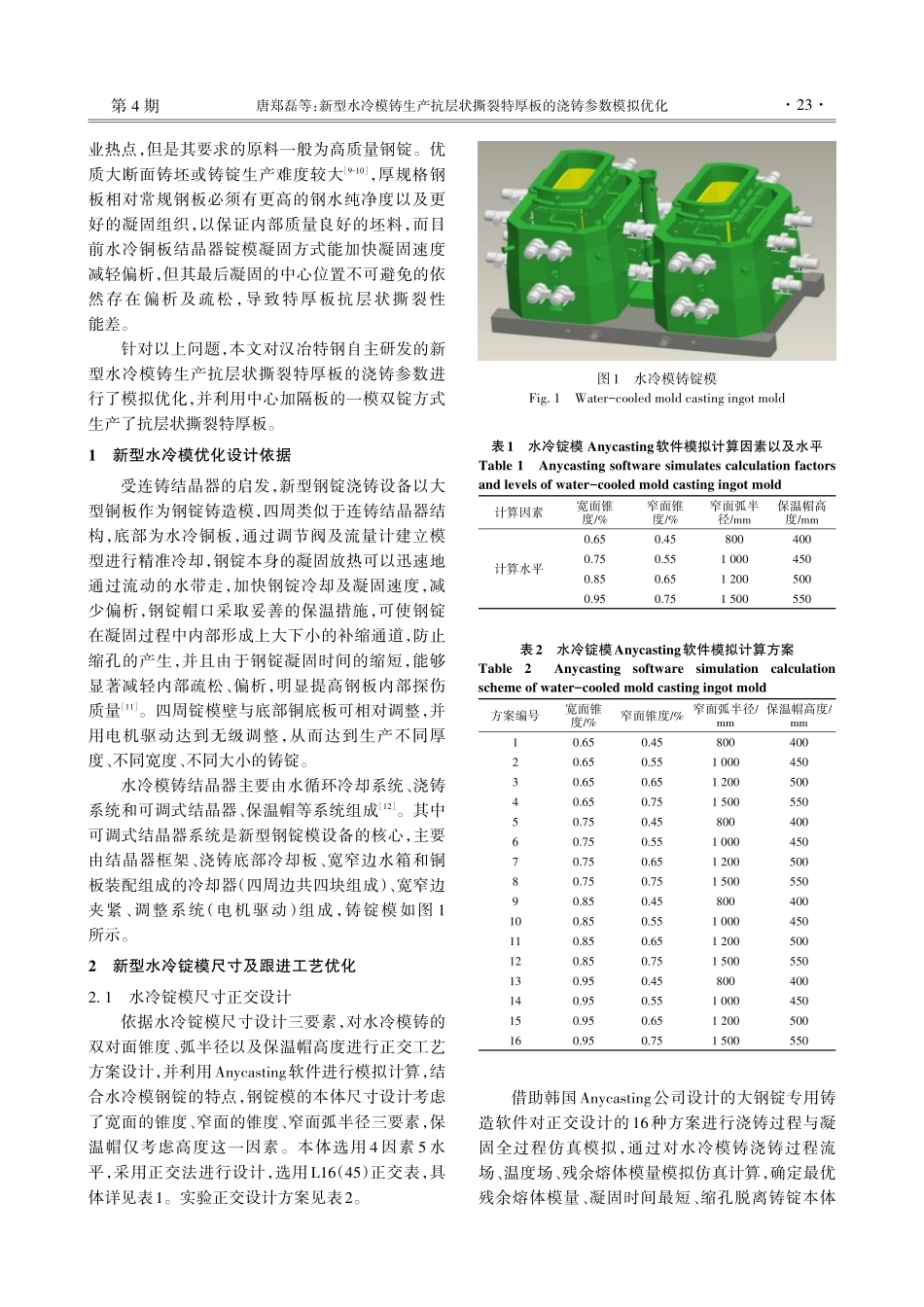

第44卷第4期2023年8月Vol.44.No.4August2023特殊钢SPECIALSTEEL新型水冷模铸生产抗层状撕裂特厚板的浇铸参数模拟优化唐郑磊1,2,许少普2,王福明1,李红洋2,陈熙2,张涛2(1北京科技大学冶金与生态工程学院,北京100083;2南阳汉冶特钢有限公司,南阳474500)摘要:新型水冷模铸锭模系统由可调整锭模、水冷铜底板、保温帽及控制系统组成,从生产抗层状撕裂性能特厚板的提料尺寸来倒推水冷模铸的尺寸,并通过Anycasting软件进行4因素5水平正交试验模拟,确定目前水冷控制系统下的最优锭模尺寸(宽面锥度0.75%,窄面锥度0.45%,窄面弧半径1500mm,保温帽高度500mm)及浇铸后2~8h跟进冷却工艺,并利用水冷模铸中心加隔板的方式,将铸锭一分为二达到一模双锭,类似定向凝固的方式,来使中心的偏析和疏松缺陷存在于坯料的表面,更易于清理,从而提高坯料质量,并可使轧制过程中渗透作用更为有效,达到生产抗层状撕裂特厚板的目的。生产200~400mm的特厚板钢板,内部质量符合标准JB/T4730.5-2005的I级及特厚板的抗层状撕裂Z35性能。关键词:新型水冷模铸;特厚板;抗层状撕裂性能;Z向DOI:10.20057/j.1003-8620.2023-00045中图分类号:TF775SimulationandOptimizationofCastingParametersforProducingLaminarTearResistantExtra-thickPlatebyTheNewTypeofWater-cooledDieCastingTangZhenglei1,2,XuShaopu2,WangFuming1,LiHongyang2,ChenXi2,ZhangTao2(1MetallurgicalandEcologicalEngineeringSchool,UniversityofScienceandTechnologyBeijing,Beijing100083,China;2NanYangHanYeSpecialIronandSteelCo.,Ltd.,Nanyang474500,China)Abstract:Thenewtypeofwater-cooledmoldcastingingotmoldsystemconsistsofanadjustableingotmold,awater-cooledcopperbottomplate,aninsulationcap,andacontrolsystem.Thesizeofthewater-cooledmoldcastingisinverselycalculatedfromthesizeofthematerialusedtoproduceathickplatewithlaminartearresistance,anda4-factor5-levelor⁃thogonaltestsimulationisconductedbyusingAnycastingsoftware,todeterminetheoptimalingotmoldsizeunderthecur⁃rentwatercoolingcontrolsystem(widesurfacetaper0.75%,narrowsurfacetaper0.45%,narrowsurfacearcradius1500mm,insulationcapheight500mm)andfollowupthecoolingprocess2to8haftercasting.Usethemethodofadd⁃ingaseparatortothecenterofthewaterc...