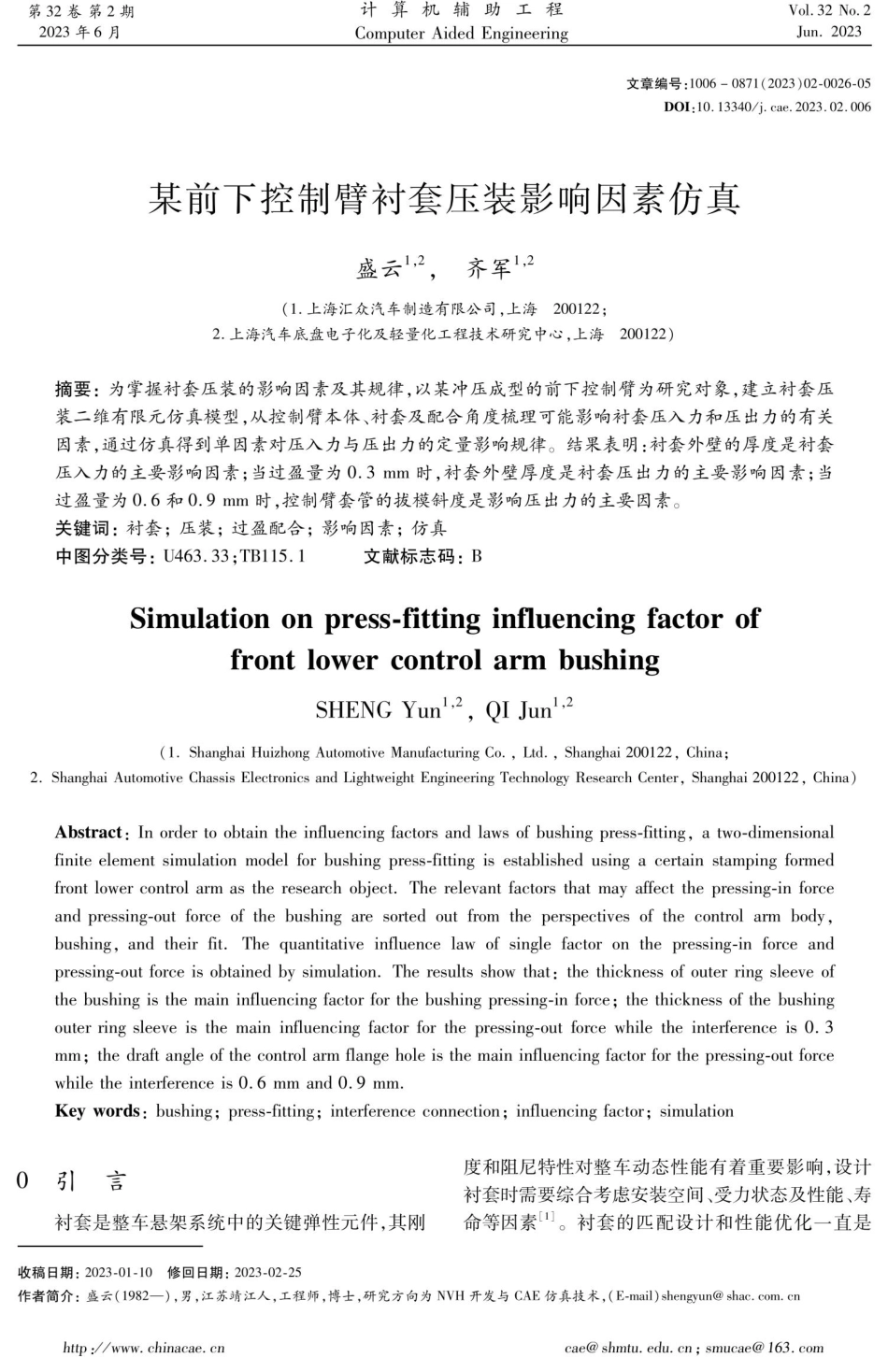

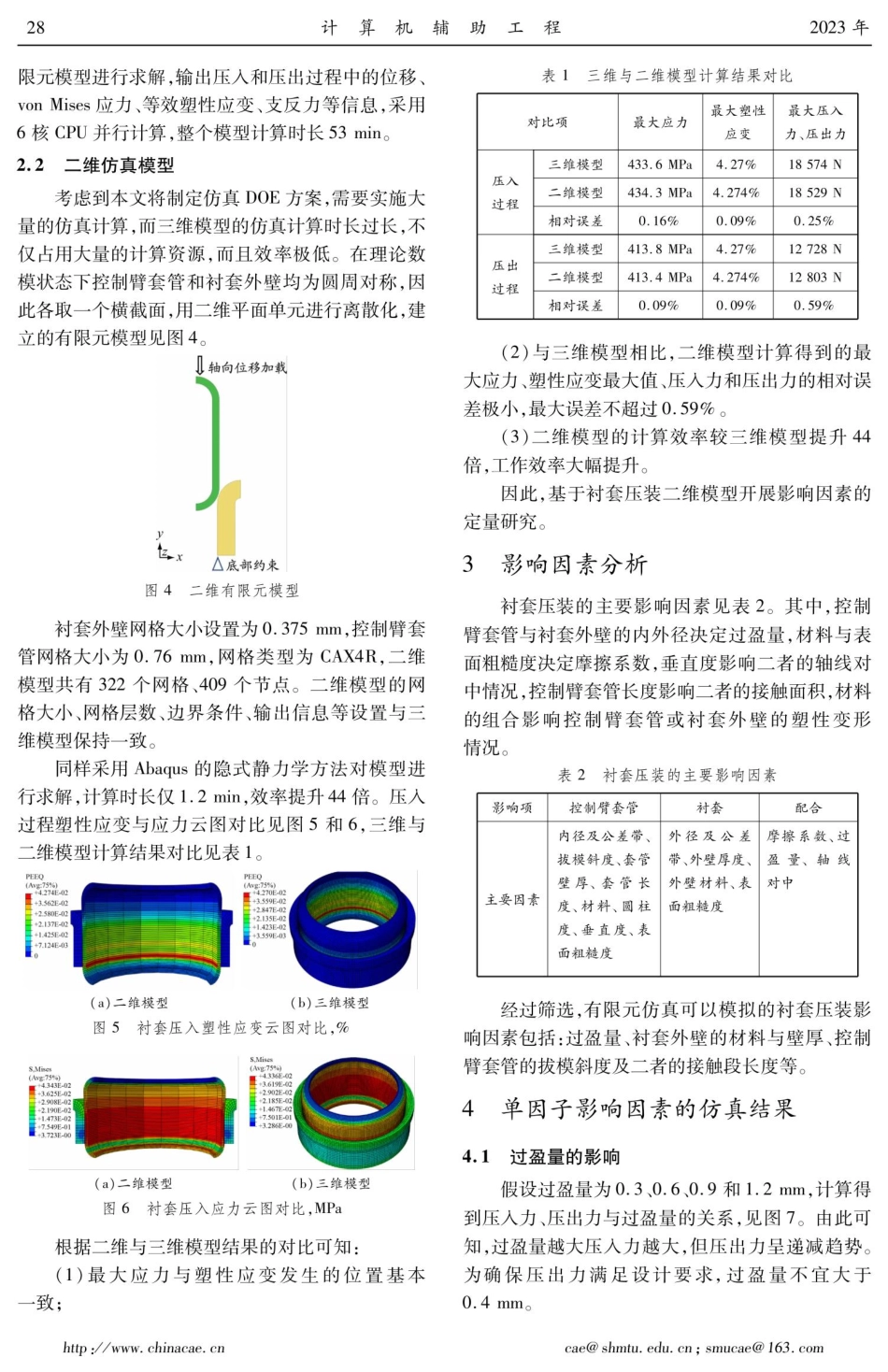

第32卷第2期2023年6月计算机辅助工程ComputerAidedEngineeringVol.32No.2Jun.2023文章编号:1006-0871(2023)02-0026-05D01:10.13340/j.cae.2023.02.006某前下控制臂衬套压装影响因素仿真盛云1.2,齐军1.2(1.上海汇众汽车制造有限公司,上海200122;2.上海汽车底盘电子化及轻量化工程技术研究中心,上海200122)摘要:为掌握衬套压装的影响因素及其规律,以某冲压成型的前下控制臂为研究对象,建立衬套压装二维有限元仿真模型,从控制臂本体、衬套及配合角度梳理可能影响衬套压入力和压出力的有关因素,通过仿真得到单因素对压入力与压出力的定量影响规律。结果表明:衬套外壁的厚度是衬套压入力的主要影响因素;当过盈量为0.3mm时,衬套外壁厚度是衬套压出力的主要影响因素;当过盈量为0.6和0.9mm时,控制臂套管的拔模斜度是影响压出力的主要因素。关键词:衬套;压装;过盈配合;影响因素;仿真中图分类号:U463.33;TB115.1Simulationonpress-fittinginfluencingfactoroffrontlowercontrolarmbushingSHENGYun'2,QIJun'.2(1.ShanghaiHuizhongAutomotiveManufacturingCo.,Ltd.,Shanghai200122,China;2.ShanghaiAutomotiveChassisElectronicsandLightweightEngineeringTechnologyResearchCenter,Shanghai200122,China)Abstract:Inordertoobtaintheinfluencingfactorsandlawsofbushingpress-ftting,atwo-dimensionalfiniteelementsimulationmodelforbushingpress-fttingisestablishedusingacertainstampingformedfrontlowercontrolarmastheresearchobject.Therelevantfactorsthatmayaffectthepressing-inforceandpressing-outforceofthebushingaresortedoutfromtheperspectivesofthecontrolarmbody,bushing,andtheirfit.Thequantitativeinfluencelawofsinglefactoronthepressing-inforceandpressing-outforceisobtainedbysimulation.Theresultsshowthat:thethicknessofouterringsleeveofthebushingisthemaininfluencingfactorforthebushingpressing-inforce;thethicknessofthebushingouterringsleeveisthemaininfluencingfactorforthepressing-outforcewhiletheinterferenceisO.3mm;thedraftangleofthecontrolarmflangeholeisthemaininfluencingfactorforthepressing-outforcewhiletheinterferenceis0.6mmand0.9mm.Keywords:bushing;press-ftting;interferenceconnection;influencingfactor;simulation0引言衬套是整车悬架系统中的关键弹性元件,其刚收...