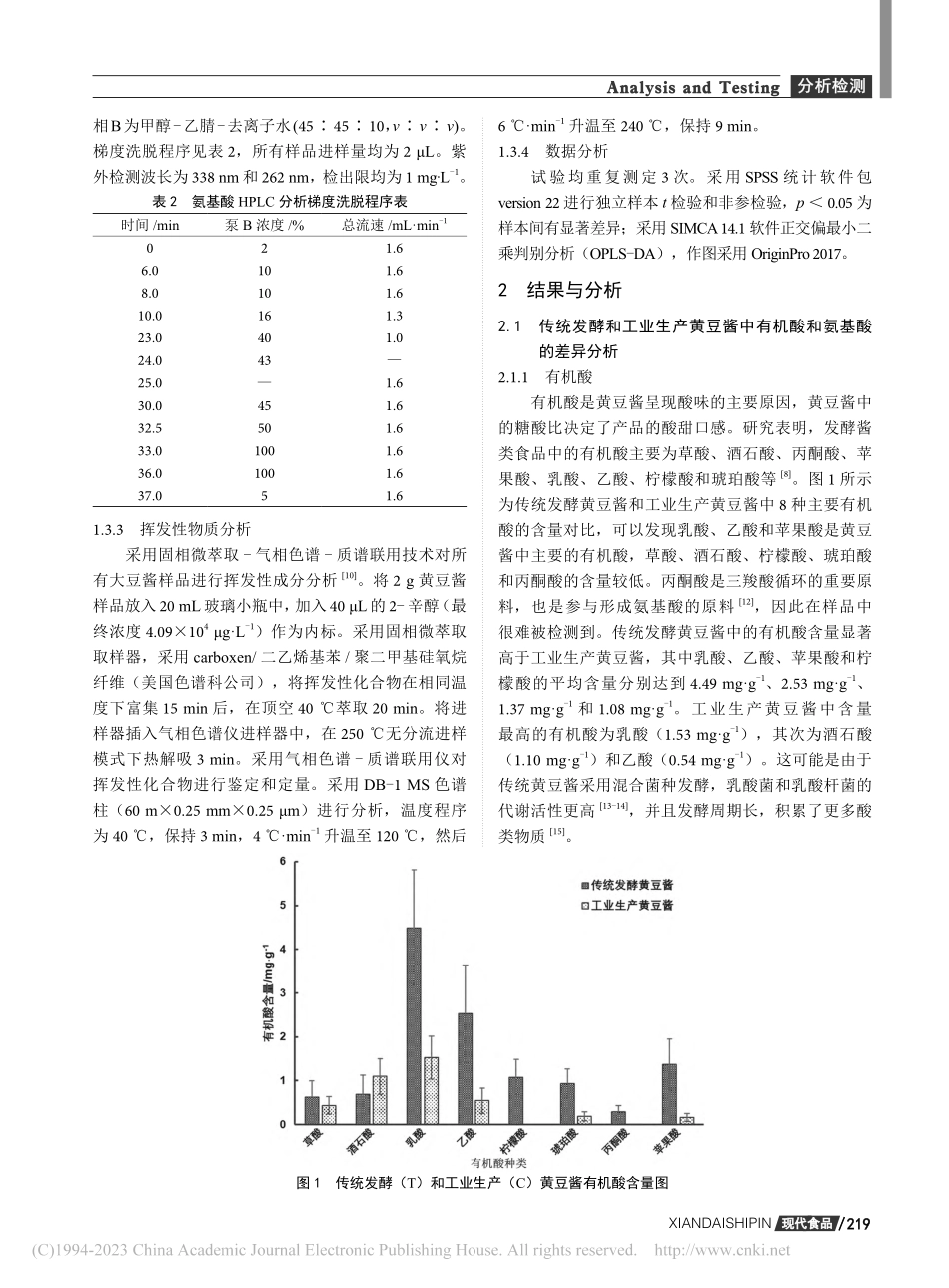

现代食品现代食品XIANDAISHIPIN217217/分析检测分析检测AnalysisandTestingdoi:10.16736/j.cnki.cn41-1434/ts.2022.24.057传统发酵和工业生产黄豆酱中风味物质的差异分析DifferencesBetweenTraditionallyFermentedandIndustriallyProducedSoybeanPaste◎张晓1,3,葛谦2,3,贾航3,曾雪君3,岳田利3,4,袁亚宏3,4(1.苏州农业职业技术学院食品科技学院,江苏苏州215008;2.宁夏农产品质量标准与检测技术研究所,宁夏银川750002;3.西北农林科技大学食品科学与工程学院,陕西杨凌712100;4.西北大学食品科学与工程学院,陕西西安710069)ZHANGXiao1,3,GEQian2,3,JIAHang3,ZENGXuejun3,YUETianli3,4,YUANYahong3,4(1.FacultyofFoodScienceandTechnology,SuzhouPolytechnicInstituteofAgriculture,Suzhou215008,China;2.NingxiaResearchInstituteofQualityStandardsandTestingTechnologyofAgriculturalProducts,Yinchuan750002,China;3.CollegeofFoodScienceandEngineering,NorthwestA&FUniversity,Yangling712100,China;4.CollegeofFoodScienceandTechnology,NorthwestUniversity,Xi’an710069,China)摘要:为了探究传统发酵黄豆酱特殊风味的来源,提高工业生产黄豆酱的风味品质,采集了东北地区传统发酵和工业生产黄豆酱样品共49份,采用高效液相色谱和固相微萃取-气相色谱-质谱联用技术对样品中的有机酸、氨基酸及挥发性风味物质进行测定,并通过正交偏最小二乘法判别分析获得对两类样品差异有主要影响的风味物质。结果表明,传统发酵黄豆酱中的有机酸和挥发性风味物质含量显著高于工业生产黄豆酱,且种类更加丰富,而氨基酸含量略低于工业生产黄豆酱;乳酸、乙酸、苹果酸、谷氨酸、丙氨酸、醇类、酯类和酸类可能是导致两类样品风味差异的主要物质。研究结果为工业生产黄豆酱风味多样化及品质提高提供了方向。关键词:黄豆酱;有机酸;氨基酸;挥发性风味物质;差异分析Abstract:Inordertoexplorethematerialsourcesofthespecialflavoroftraditionallyfermentedsoybeanpasteandimprovetheflavorqualityofindustriallyproducedsoybeanpaste,49samplescollectedfromNortheastChinawereinvolvedinthisresearch.Highperformanceliquidchromatographyandsolidphasemicroextraction-gaschromatography-massspectrometrywereusedtoanalysetheorganicacid,aminoacidandvolatileflavorcompoundinthesamples.Theflavorcompoundsthathadamajorimpactonthediffe...