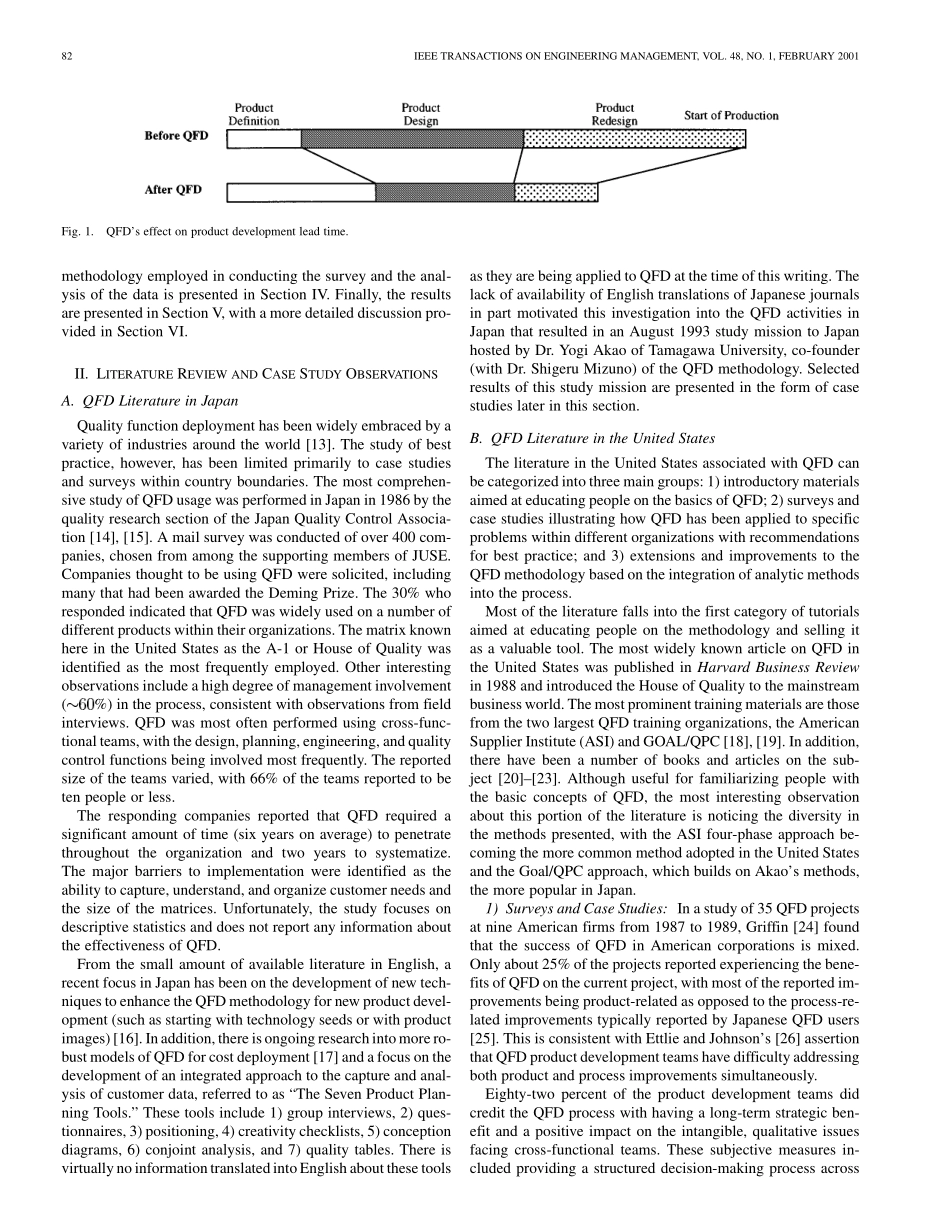

IEEETRANSACTIONSONENGINEERINGMANAGEMENT,VOL.48,NO.1,FEBRUARY200181KeyFactorsintheSuccessfulApplicationofQualityFunctionDeployment(QFD)JohnJ.Cristiano,JeffreyK.Liker,andChelseaC.White,III,Fellow,IEEEAbstract—Intheproductdesignanddevelopmentprocess,qualityfunctiondeployment(QFD)providesacomprehensive,systematicapproachtoensurethatnewproductsmeetorexceedcustomerexpectations.Thispaperreportsontheresultsofasurveyofmorethan400companiesintheUnitedStatesandJapanusingQFD.TheobjectiveofthestudywastounderstandthekeyfactorsthatresultinthesuccessfulapplicationofQFD.TheresearchquestionsinvestigatedinthisstudyweredevelopedbothinductivelyfromQFDcasestudiesintheUnitedStatesandJapananddeductivelyfromtheliterature.Regressionanalysisestimatestheeffectsoforganizationalcharacteristics,datasources,andQFDtoolsandtechniquesonQFDimprovementsintheproductandprocess.TheresultsshowthatQFDismostlikelytohaveapositiveimpactwhenthereismanagementsupportforQFDandnewcustomerdataspecificallycollectedfortheQFDstudyareused.ThebenefitsofQFDareindependentofthetoolsandtechniquesusedaspartoftheQFDstudy.IndexTerms—Adoptionoftechnology,implementationoftech-nology,QFD,qualityfunctiondeployment,qualitytools.I.INTRODUCTIONSUCCESSFULcompaniesintoday’sdynamicglobaleconomyarethosethatareabletoefficientlydesign,develop,andmanufactureproductsthatwillbepreferredbycustomersoverthoseofferedbycompetitors.Theemergenceofaglobaleconomycharacterizedbyintenseinternationalcompetition,fragmentedmarketsofdiscriminatingcustomers,andrapidtechnologicalchangehasprovokedanewindustrialrevolution[1].Atthecenterofthisrevolutionisaneedtodeliverproductdesignsthatmeetthesecustomerneedswhilemakingthedesignsmanufacturableatacompetitivecostwithinveryshorttimeframes.Aphilosophyforrestructuringtheseprocesses,calledconcurrentengineering(CE)(a.k.a.simul-taneousengineeringoroverlappingtasks),wasrediscoveredbyU.S.industrythroughthestudyofsuccessfulJapaneseautomobilemanufacturersduringthe1980s[1],[2].Inthisperiod,companiesrealignedtheirentireorg...