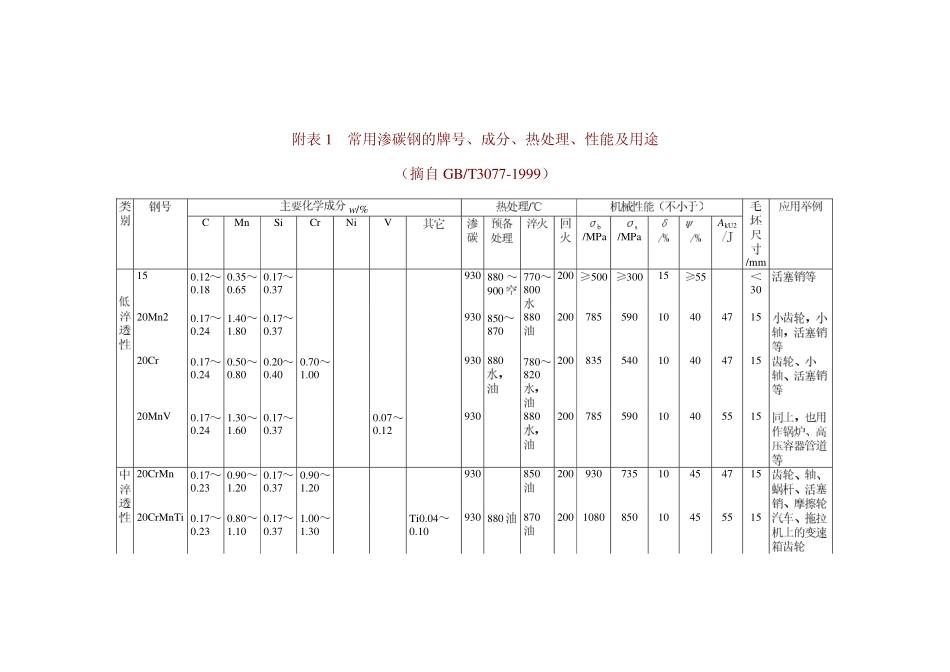

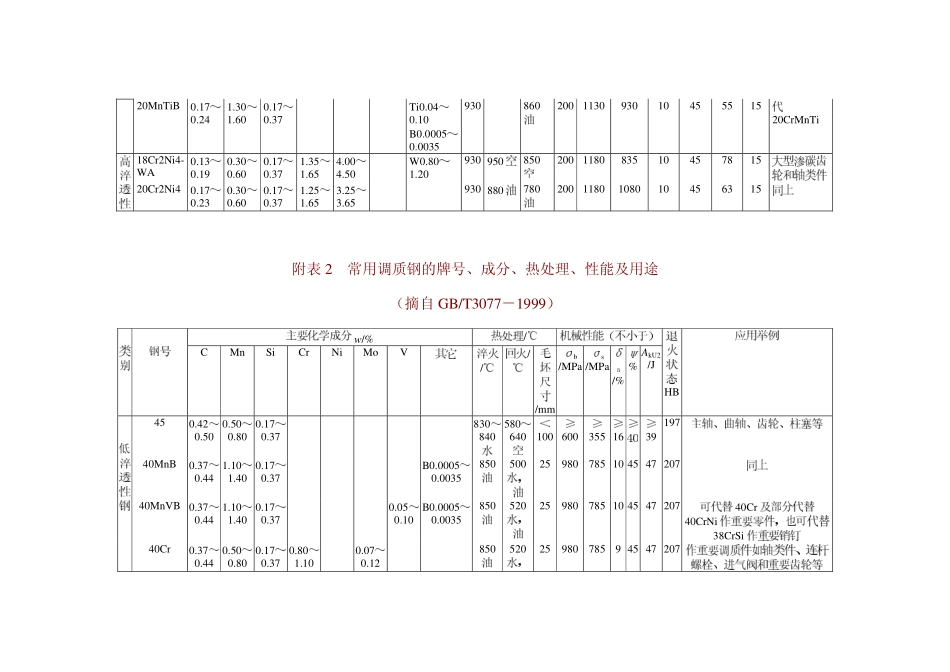

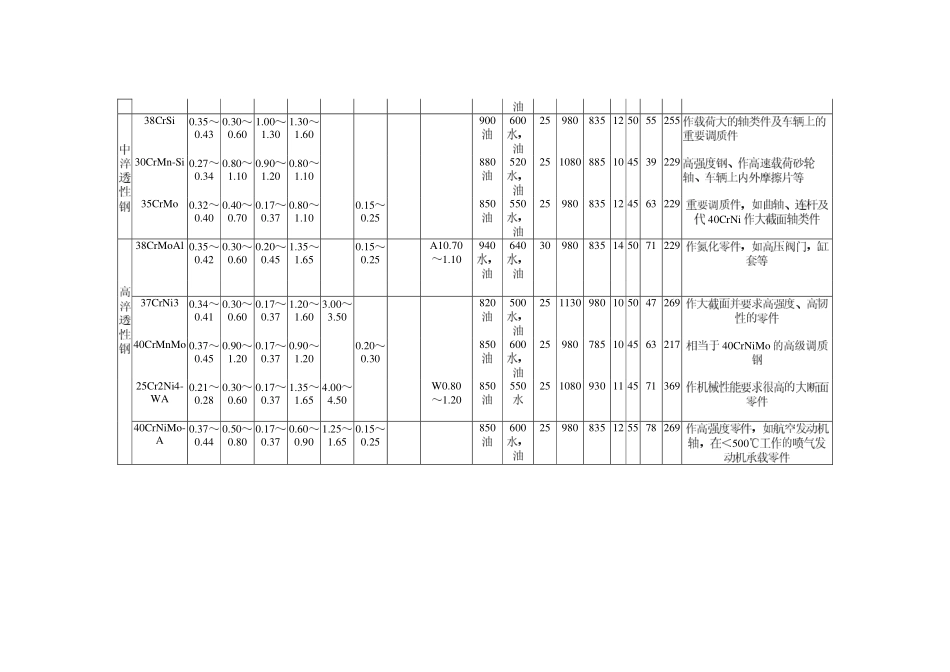

附表1常用渗碳钢的牌号、成分、热处理、性能及用途(摘自GB/T3077-1999)主要化学成分w/%热处理/℃机械性能(不小于)类别钢号CMnSiCrNiV其它渗碳预备处理淬火回火σb/MPaσs/MPaδ/%ψ/%AkU2/J毛坯尺寸/mm应用举例150.12~0.180.35~0.650.17~0.37930880~900空770~800水200≥500≥30015≥55<30活塞销等20Mn20.17~0.241.40~1.800.17~0.37930850~870880油20078559010404715小齿轮,小轴,活塞销等20Cr0.17~0.240.50~0.800.20~0.400.70~1.00930880水,油780~820水,油20083554010404715齿轮、小轴、活塞销等低淬透性20MnV0.17~0.241.30~1.600.17~0.370.07~0.12930880水,油20078559010405515同上,也用作锅炉、高压容器管道等20CrMn0.17~0.230.90~1.200.17~0.370.90~1.20930850油20093073510454715齿轮、轴、蜗杆、活塞销、摩擦轮中淬透性20CrMnTi0.17~0.230.80~1.100.17~0.371.00~1.30Ti0.04~0.10930880油870油200108085010455515汽车、拖拉机上的变速箱齿轮20MnTiB0.17~0.241.30~1.600.17~0.37Ti0.04~0.10B0.0005~0.0035930860油200113093010455515代20CrMnTi18Cr2Ni4-WA0.13~0.190.30~0.600.17~0.371.35~1.654.00~4.50W0.80~1.20930950空850空200118083510457815大型渗碳齿轮和轴类件高淬透性20Cr2Ni40.17~0.230.30~0.600.17~0.371.25~1.653.25~3.65930880油780油2001180108010456315同上附表2常用调质钢的牌号、成分、热处理、性能及用途(摘自GB/T3077-1999)主要化学成分w/%热处理/℃机械性能(不小于)类别钢号CMnSiCrNiMoV其它淬火/℃回火/℃毛坯尺寸/mmσb/MPaσs/MPaδ5/%ψ%AkU2/J退火状态HB应用举例450.42~0.500.50~0.800.17~0.37830~840水580~640空<100≥600≥355≥16≥40≥39197主轴、曲轴、齿轮、柱塞等40MnB0.37~0.441.10~1.400.17~0.37B0.0005~0.0035850油500水,油25980785104547207同上40MnVB0.37~0.441.10~1.400.17~0.370.05~0.10B0.0005~0.0035850油520水,油25980785104547207可代替40Cr及部分代替40CrNi作重要零件,也可代替38CrSi作重要销钉低淬透性钢40Cr0.37~0.440.50~0.800.17~0.370.80~1.100.07~0.12850油520水,2598078594547207作重要调质件如轴类件、连杆螺栓、进气阀和重要齿轮等油38CrSi0.35~0.430.30~0.601.00~1.301.30~1.60900油600水,油25980835125055255作载荷大的轴类件及车辆上的重要调质件30CrMn-Si0.27~0.340.80~1.100.90~1.200.8...